Improved vacuumizing sealing machine capable of automatically locking cover

A vacuum sealing and vacuuming technology, used in packaging sealing/fastening, external support, transportation packaging, etc., can solve the problem of limited strength of solenoid valve on-off valve, large volume of vacuum sealing machine, and difficult to extract air from smooth bags, etc. problems, to achieve the effect of high pressure relief, improve vacuum sealing efficiency, and save vertical space.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0063] The following are only preferred embodiments of the present invention, and therefore do not limit the protection scope of the present invention.

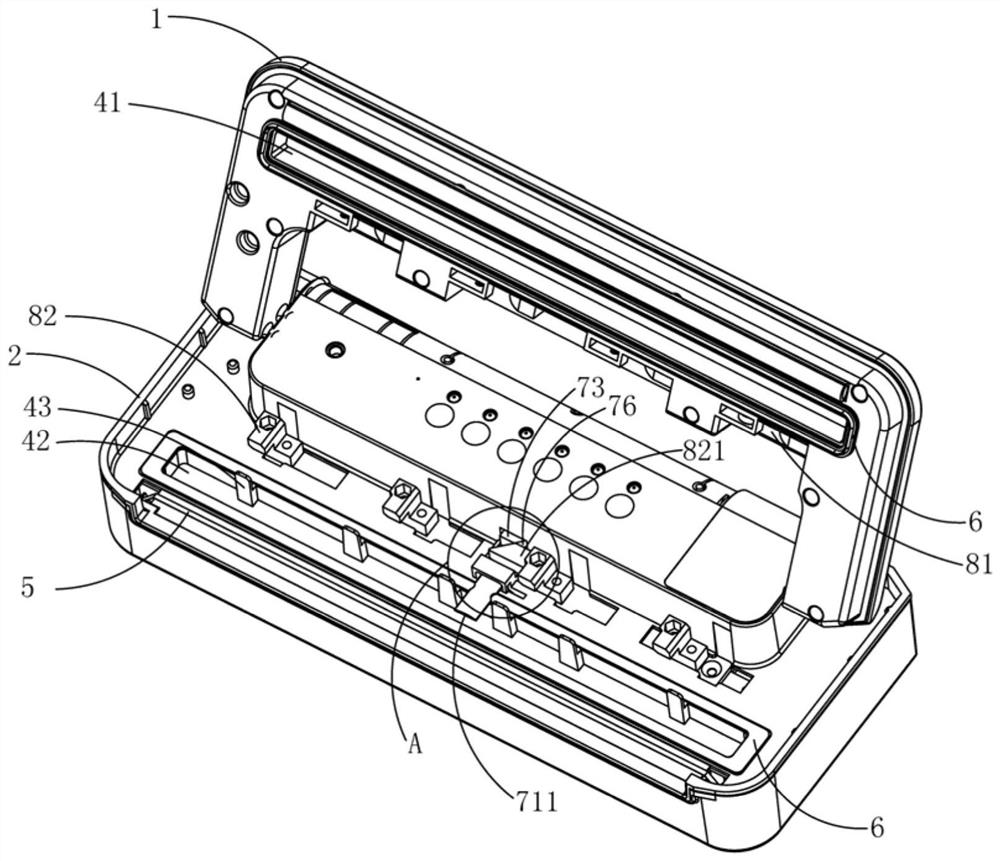

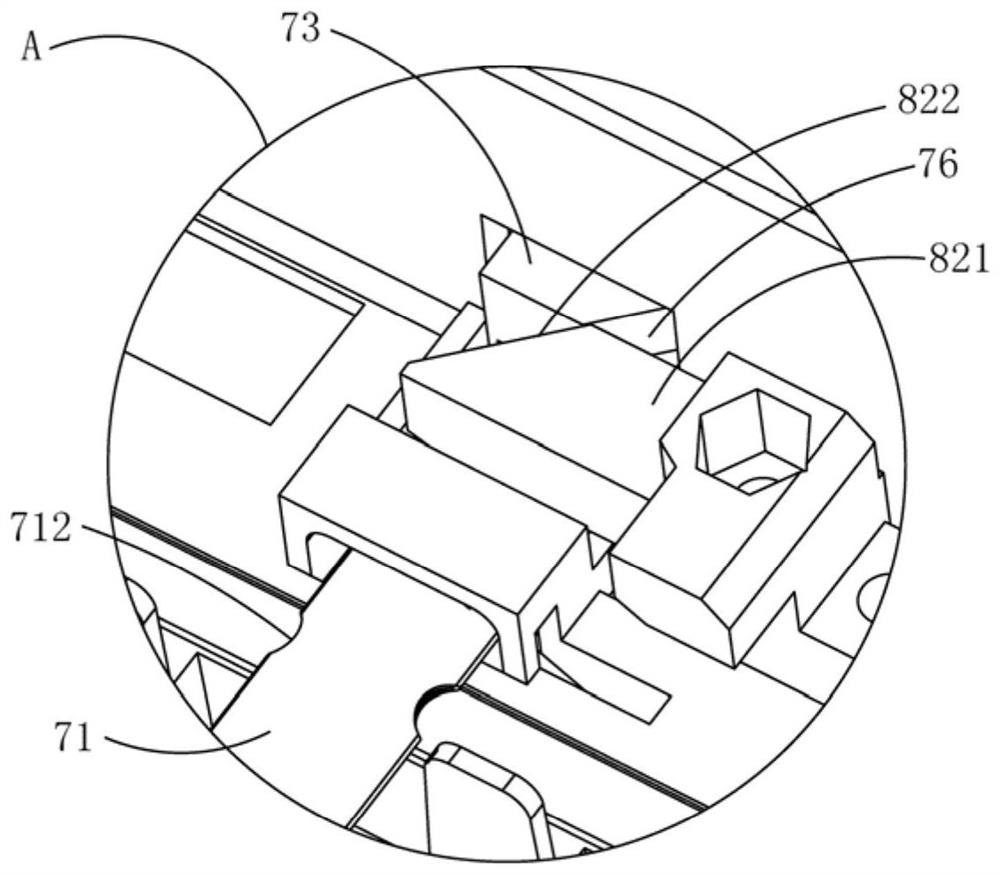

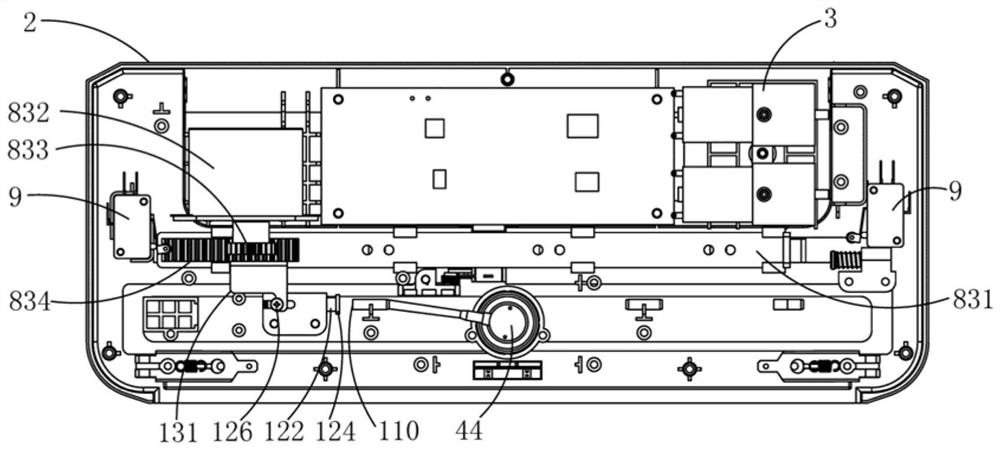

[0064] An improved vacuum sealing machine with automatic lid locking, such as Figure 1 to Figure 11 As shown, it includes an upper cover 1, a lower seat 2 hinged to the rear side of the upper cover 1, an automatic cover locking mechanism and a control circuit for locking the upper cover 1 and the lower seat 2, and a vacuum pump 3 electrically connected to the control circuit. , the upper cover 1 and / or the lower seat 2 is provided with a vacuum device electrically connected to the control circuit, and the front side of the upper cover 1 and / or the lower seat 2 is provided with a heat-sealing assembly 5 electrically connected to the control circuit, which is characterized in that : the automatic cover lock mechanism includes a cover drive mechanism, at least two cover slots 81, a cover slider 82 corresponding to each cover sl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com