Large-space 3D printing machine based on light mechanical arm

A 3D printer and robotic arm technology, used in manufacturing auxiliary devices, processing drive devices, and processing data acquisition/processing, etc., can solve the problems of lack of precision, space limitations, and high load-bearing of the robotic arm, so as to improve working space and save money. The effect of reducing vertical space and equipment cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The technical solutions of the present invention will be described below in conjunction with the drawings and embodiments.

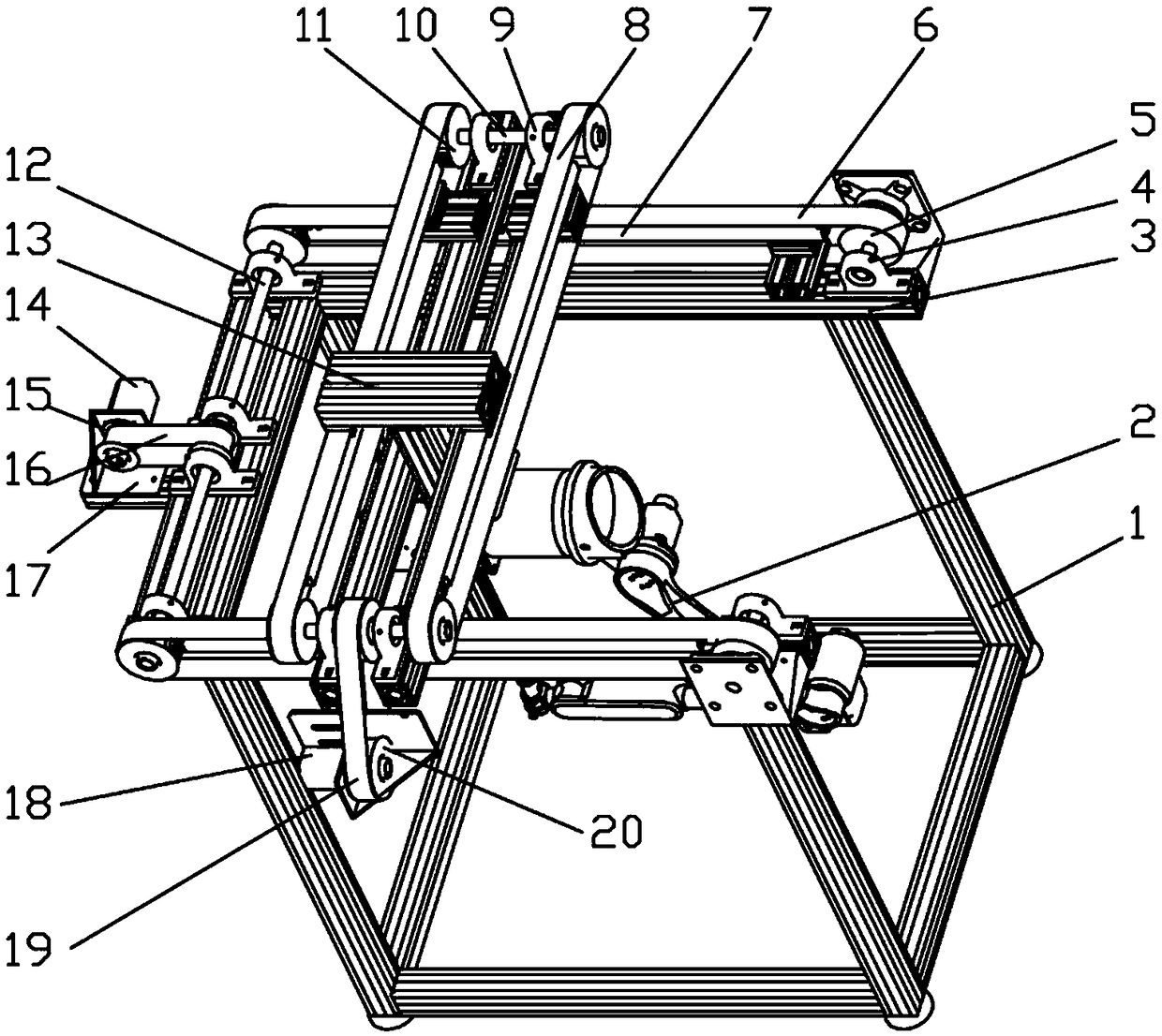

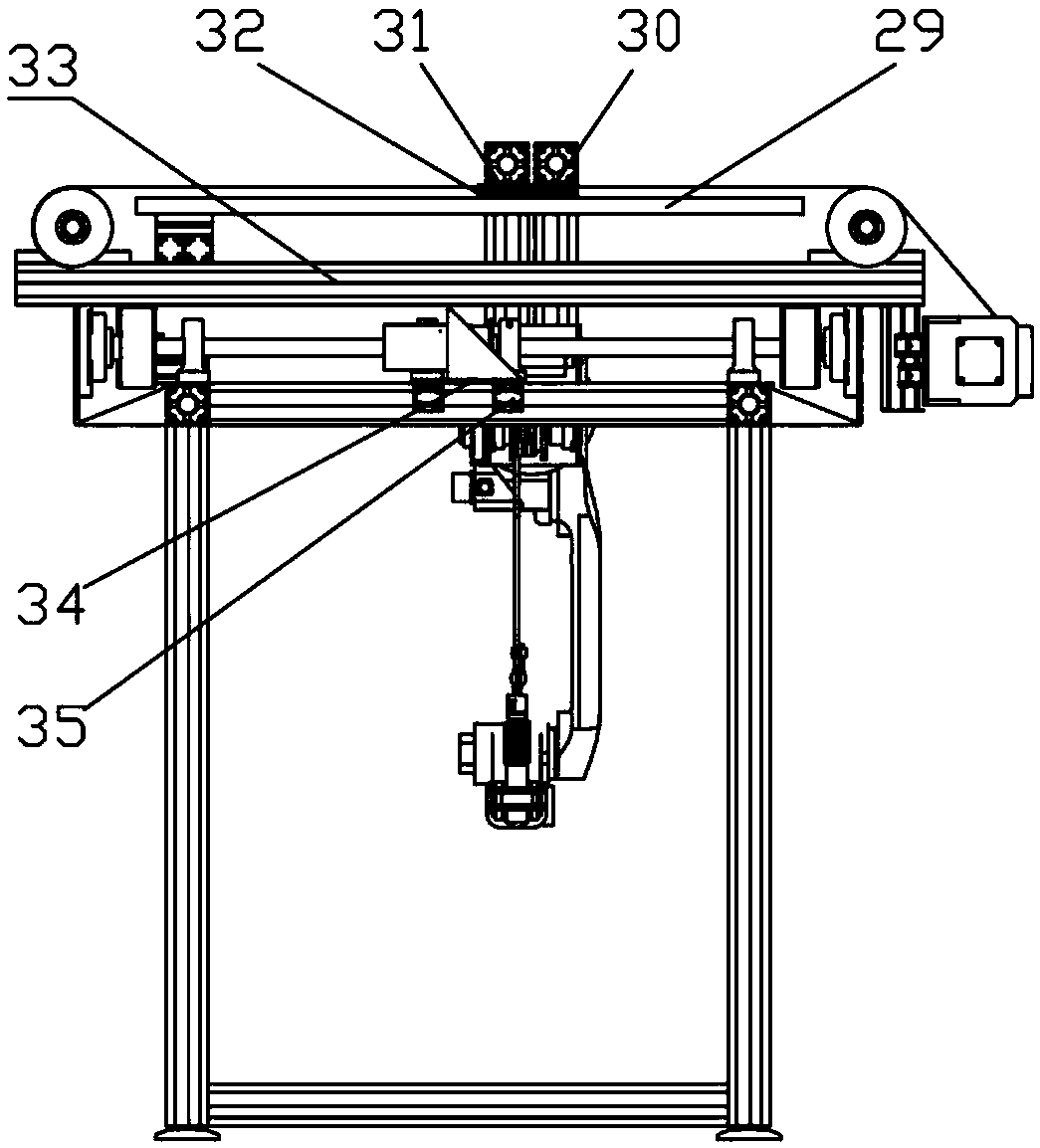

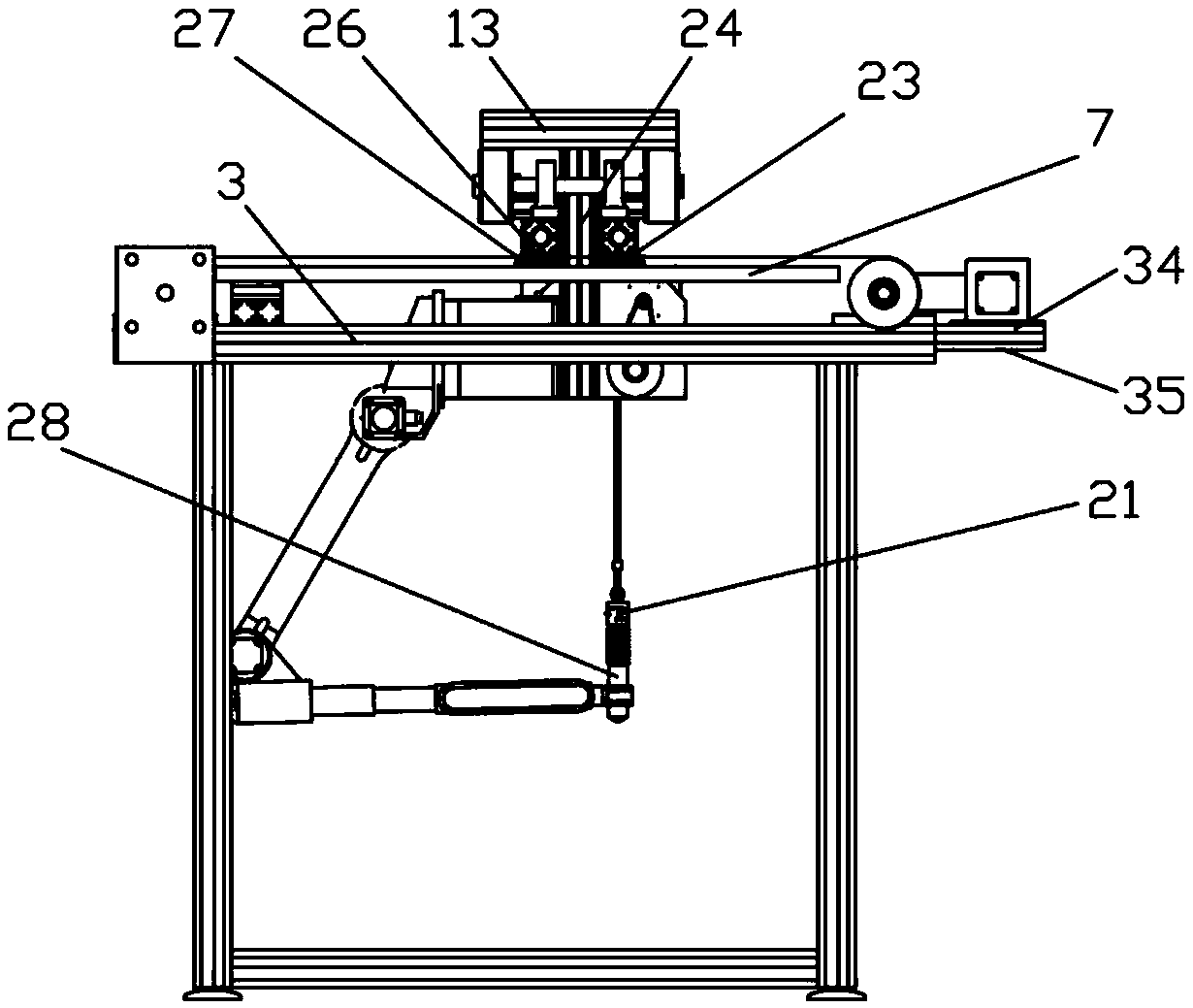

[0027] Such as Figure 1 to Figure 7 As shown, a large-space 3D printer based on a light-duty mechanical arm according to the present invention includes a support frame 1, an X-axis beam 3 is arranged on the support frame 1, and the X-axis beam 3 is provided with a The sliding Y-axis beam 33 is provided with a Z-axis beam 13 that can slide along the length direction of the Y-axis beam 33. The Z-axis beam 13 is connected with a three-degree-of-freedom mechanical arm 2 and a steel rope through a Z-axis vertical beam 24. - The spring traction device 21, the three-degree-of-freedom mechanical arm 2 is fixedly connected with the steel rope-spring traction device 21. The above constitutes the basic structure of the present invention.

[0028] In practical application, the supporting frame 1 of the present invention is composed of a plurality of column...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com