Electric drive axle structure with double motors and working method of electric drive axle structure

An electric drive, dual-motor technology, applied in the field of automobile transmission system, can solve the problems of large layout space of high-power motors and reducers, affecting vehicle passability, low reliability, etc., to facilitate installation and later maintenance, and improve packaging flexibility The effect of low performance and low transmission efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

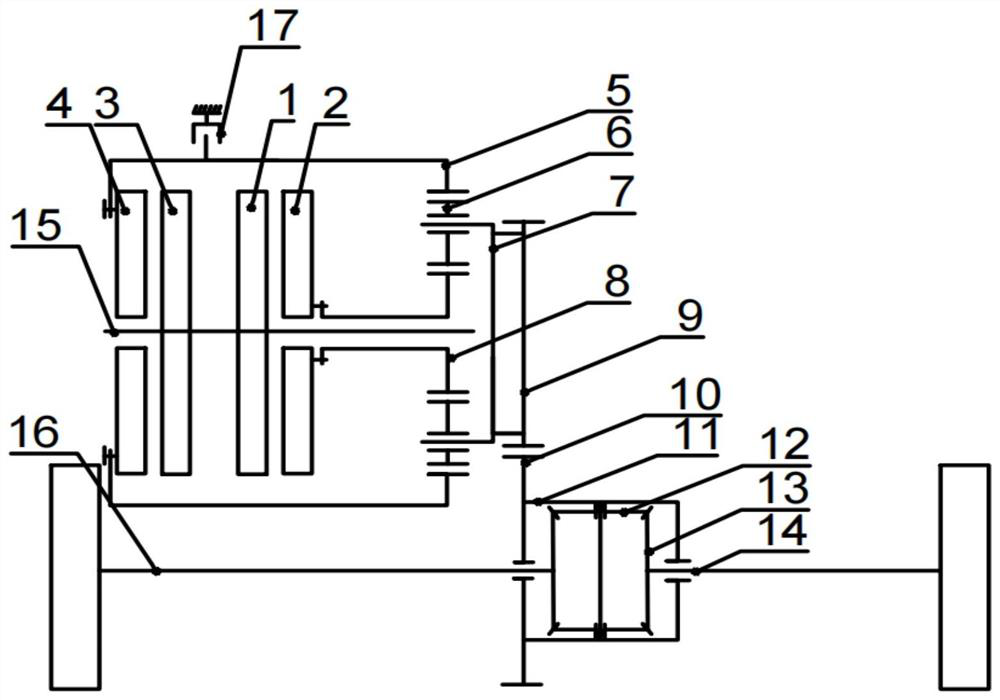

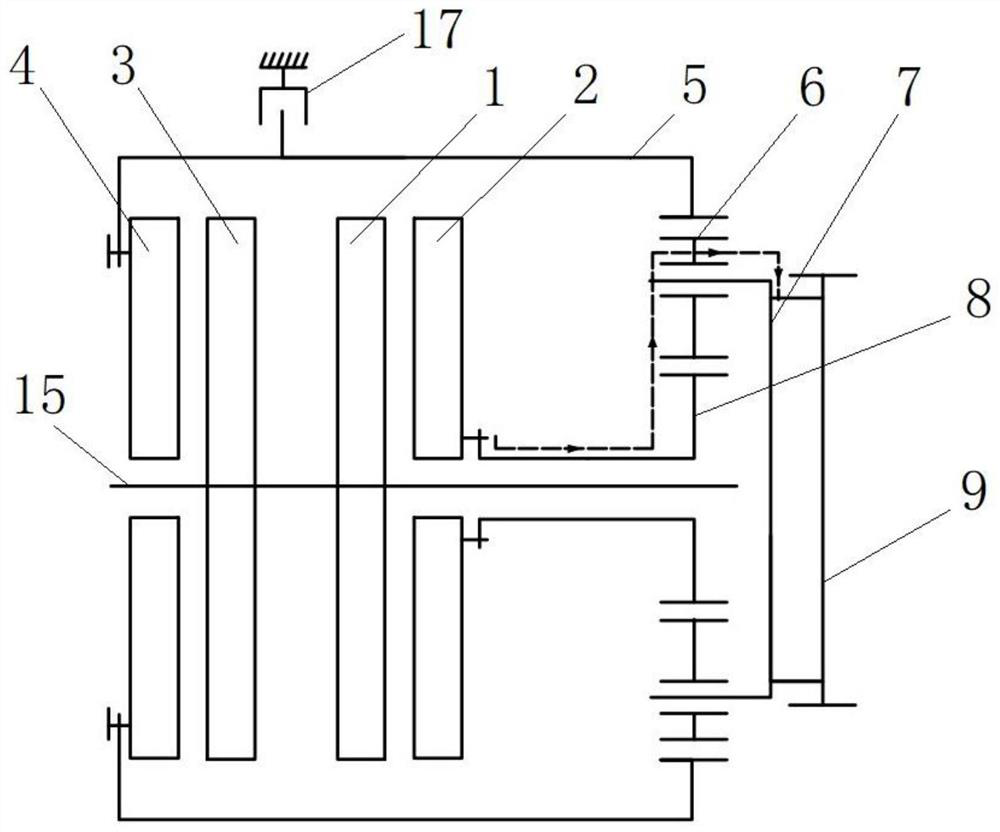

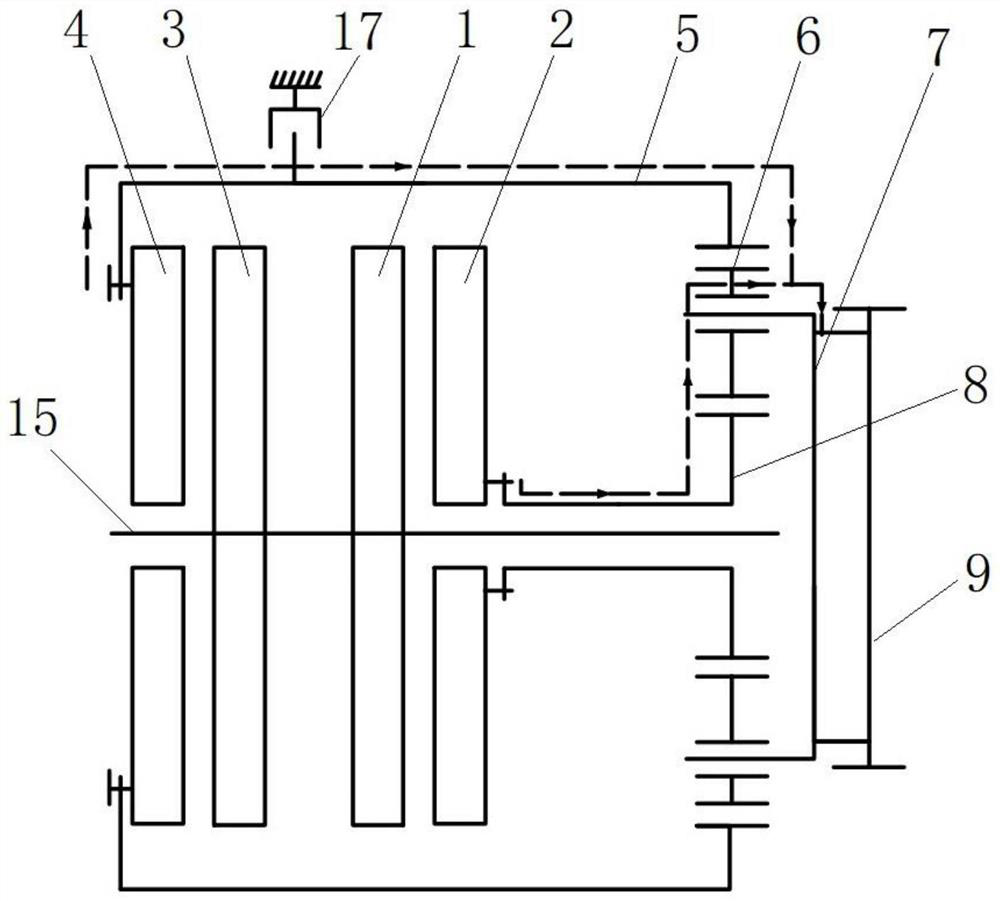

[0044] figure 1 It is a schematic diagram of the overall structure of the electric drive axle structure with dual motors of the present invention, including a first motor, a second motor, an epicyclic gear train, a driving gear 9, a driven gear 10, a differential, a driving half shaft and a brake 17;

[0045]The first motor comprises the first motor stator 1 and the first motor rotor 2, the second motor comprises the second motor stator 3 and the second motor rotor 4, the first motor stator 1, the first motor rotor 2, the second motor stator 3 and The second motor rotor 4 is successively arranged on the shaft 15 from left to right; the epicyclic gear train includes the ring gear 5, the planet carrier 7, the sun gear 8 and the planetary gear 6; the first motor rotor 2 is fixedly connected with the sun gear 8, and the second The motor rotor 4 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com