Dust removal device for plate

A technology for a dust removal device and a board, which is applied in the directions of removing smoke and dust, cleaning methods and utensils, and a cleaning method using gas flow, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

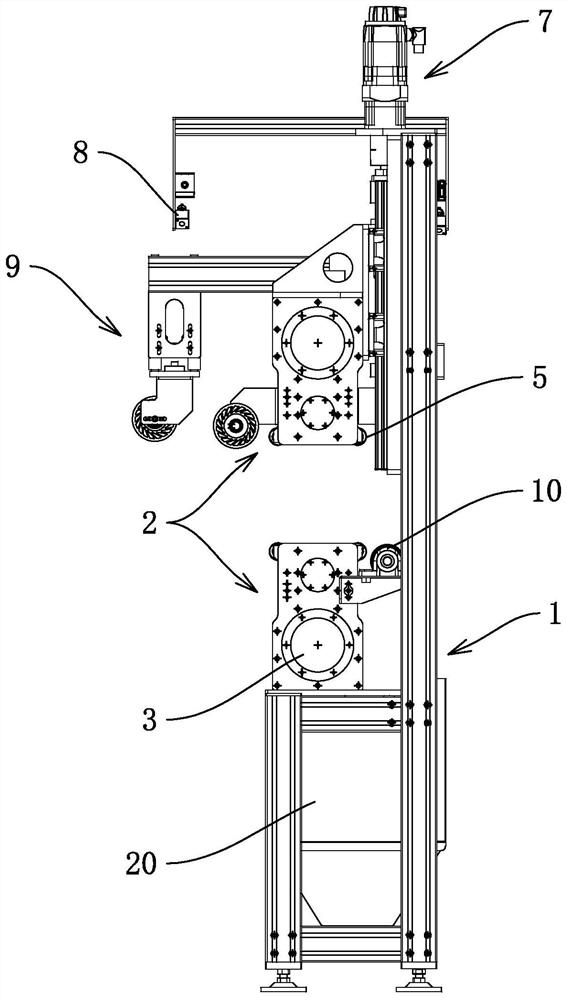

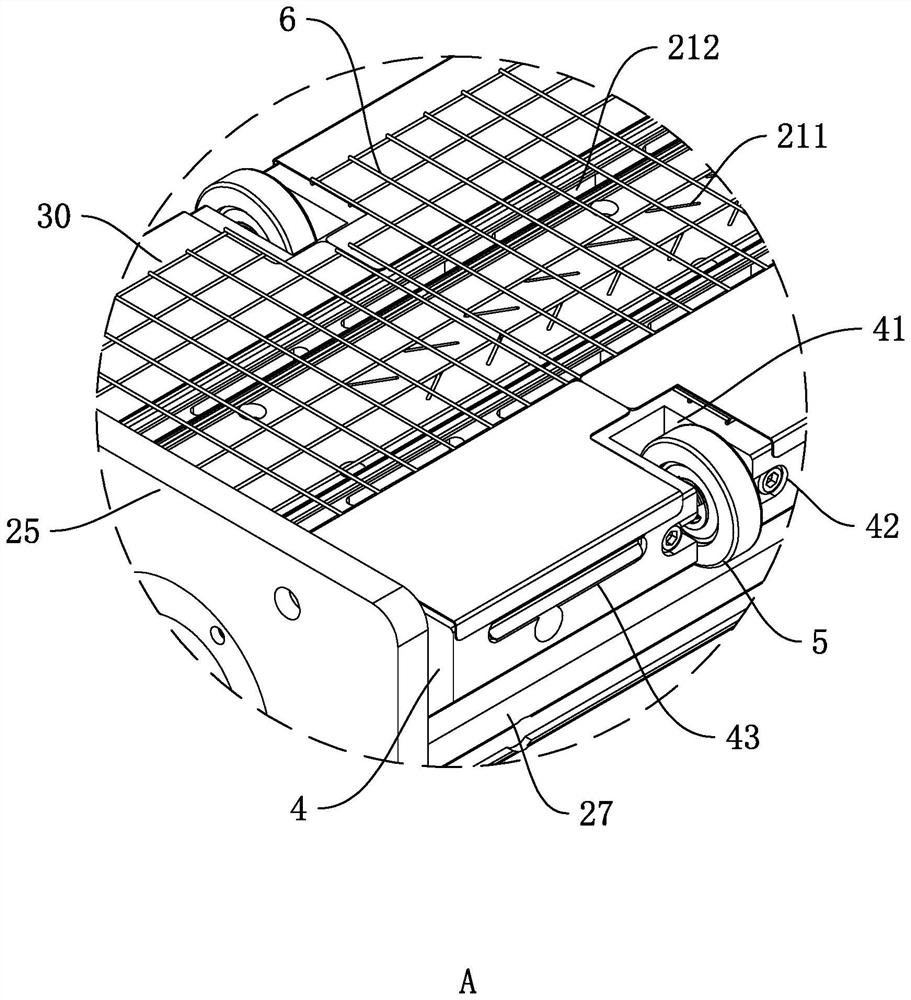

[0037] Attached to the following Figure 1-8 The present invention will be described in further detail.

[0038] The embodiment of the present invention discloses a dust removal device for plates.

[0039] refer to figure 1 and figure 2 , The dust removal device for plates includes a dust removal frame 1 , two dust removal assemblies 2 installed on the dust removal frame 1 , and an adjustment assembly 7 for adjusting the distance between the two dust removal assemblies 2 . The two dust removal assemblies 2 have the same structure and are arranged up and down. The two dust removal assemblies 2 are arranged in a horizontal mirror image, and a cleaning gap is formed between the two dust removal assemblies 2. A dust removal assembly 2 cleans the dust on and below the board. Among them, the dust removal component 2 can perform blowing and dust collection operations at the same time, the dust removal component 2 can blow off the dust on the surface of the board, and the dust re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com