NVP/GO/CNT flexible integrated membrane electrode and preparation method thereof

A membrane electrode and flexible technology, applied in the field of flexible integrated NVP/GO/CNT membrane electrode and its preparation, can solve problems such as reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0021] The invention provides a method for preparing a flexible integrated NVP / GO / CNT membrane electrode, comprising the following steps:

[0022] (1) Configure NVP, GO, and CNT materials as solutions respectively;

[0023] (2) mixing the three solutions obtained in the step (1) to obtain a mixed solution;

[0024] (3) The mixed solution was vacuum filtered and dried to obtain the NVP / GO / CNT membrane electrode.

[0025] In the present invention, the NVP material is preferably prepared by a sol-gel method or a solid-phase method, more preferably by a sol-gel method. The NVP particles prepared by the sol-gel method are more uniform and nanoscale.

[0026] In the present invention, the GO is prepared by chemical method, preferably modified Hummer's method, Brodie method or Staudenmaier method, more preferably modified Hummer's method.

[0027] In the present invention, there is no special regulation on the source of the CNT material, and the CNT well-known to those skilled in ...

Embodiment 1

[0035] Add 80mg of NVP into 20mL of deionized water, sonicate for 60min, then stir for 40min to prepare NVP dispersion; add 10mg of GO to 10mL of deionized water, sonicate for 120min, then stir for 30min to prepare GO dispersion; add 10mg of CNT into 20mL of deionized water , sonicated for 160 min, and then stirred for 50 min to prepare the CNT dispersion; under the condition of GO stirring, use a disposable dropper to sequentially add the NVP and CNT dispersion into the GO dispersion, and stir at 400 r / min for 60 min. , using a disposable dropper to draw 3mL of the mixed solution dropwise onto the Celgard membrane for vacuum filtration, after peeling off at room temperature, put it in a vacuum oven at 110°C, and dry for 12h to obtain NVP / GO / CNT flexible integrated composite membrane electrode .

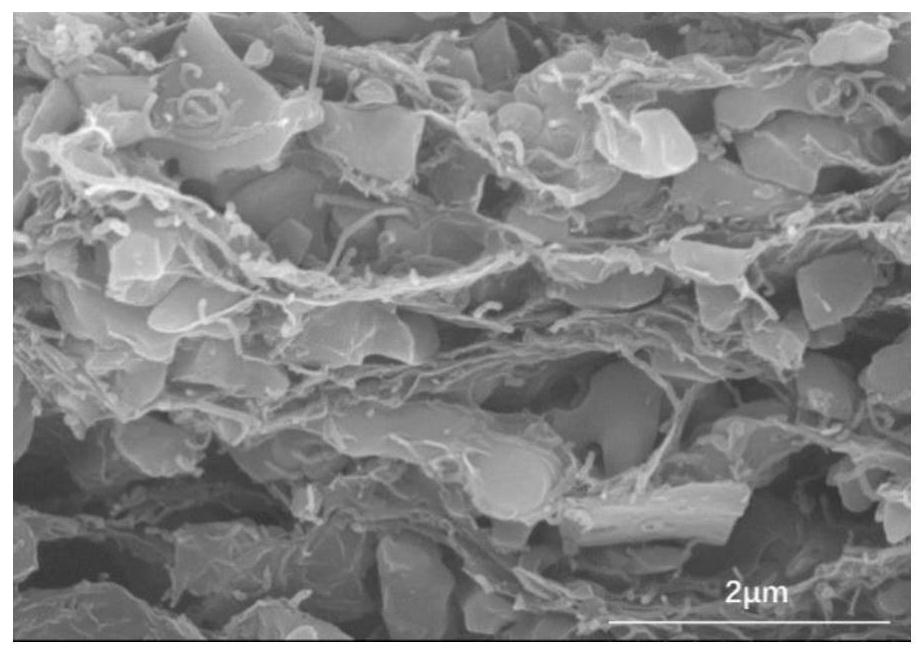

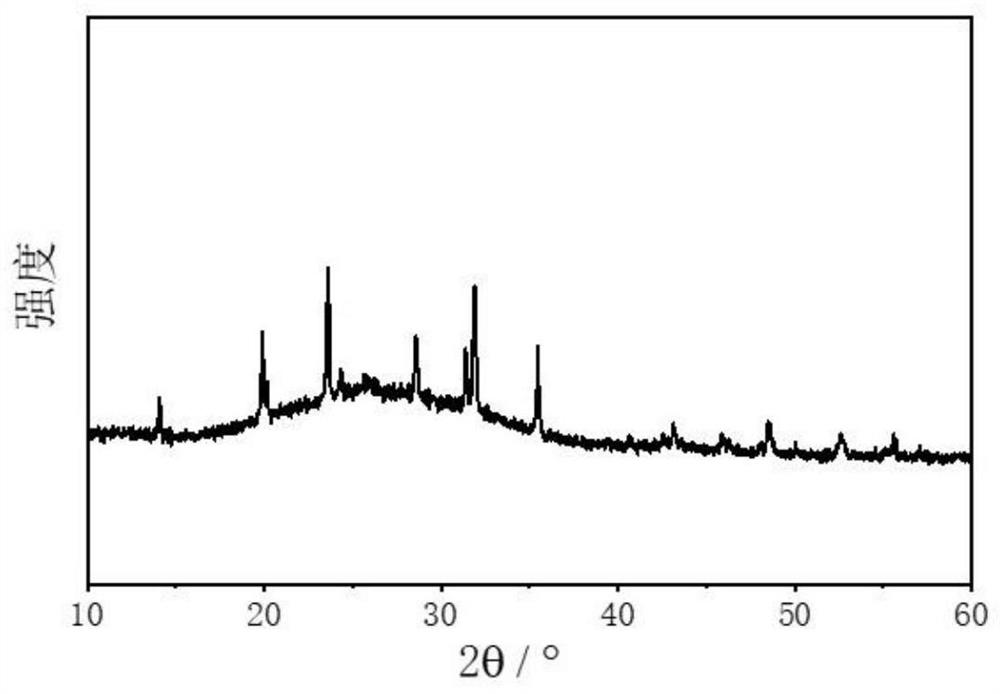

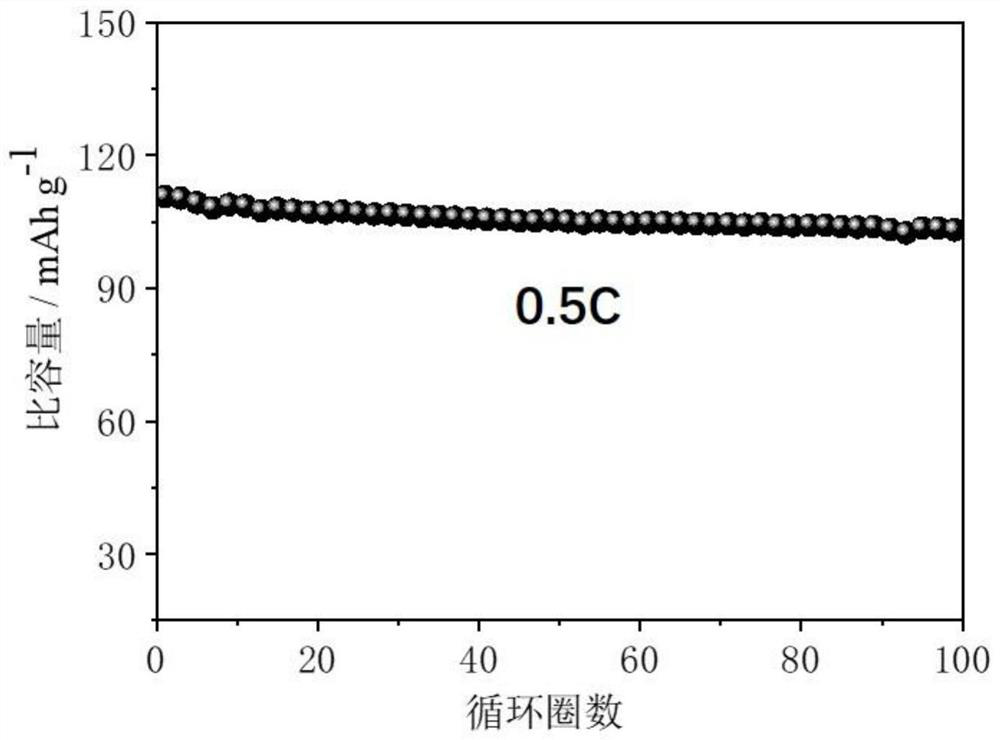

[0036] The obtained NVP / GO / CNT flexible integrated composite membrane electrode was scanned with an electron microscope, and the results are as follows: figure 1 shown; from figure...

Embodiment 2

[0050] Add 28mg of NVP into 10mL of deionized water, sonicate for 60min, then stir for 40min to prepare NVP dispersion; add 4mg of GO to 4mL of deionized water, sonicate for 150min, then stir for 60min to prepare GO dispersion; add 8mg of CNT into 16mL of deionized water , sonicated for 120min, and then stirred for 50min to prepare the CNT dispersion; under the condition of GO stirring, use a disposable dropper to sequentially add the NVP and CNT dispersion to the GO dispersion, and stir at 400r / min for 60min. , use a disposable dropper to draw 2mL of the mixed solution dropwise onto the Celgard membrane for vacuum filtration. After peeling off at room temperature, put it in a vacuum oven at 110°C and dry for 12h to obtain NVP / GO / CNT flexible integrated composite membrane electrode .

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com