Simulation system and method for laser cutting production line

A technology of laser cutting and simulation system, which is applied in the direction of manufacturing computing system, data processing application, comprehensive factory control, etc., and can solve the problems of low control logic test efficiency and poor intuition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

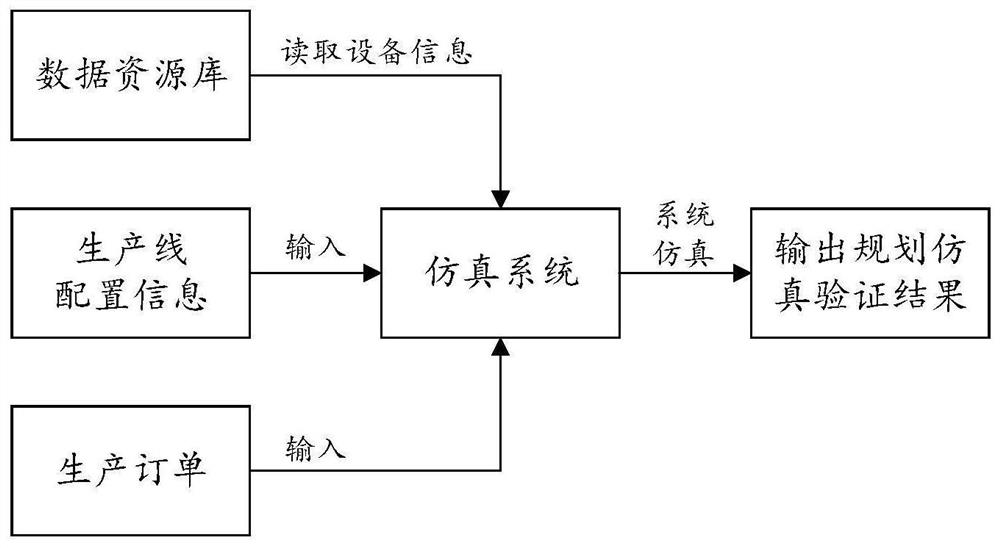

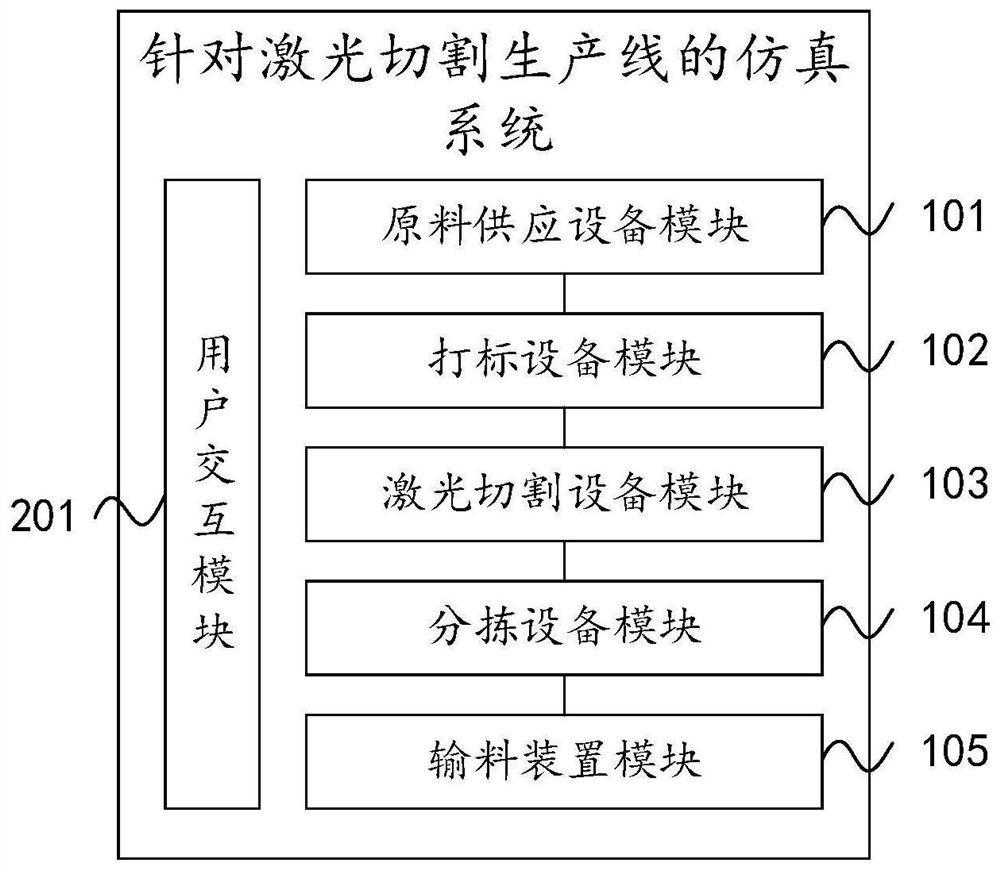

[0050] Aiming at the problems of low efficiency and poor intuitiveness in planning, verifying, and controlling logic testing of a real laser cutting production line in the prior art, this embodiment provides a simulation system for a laser cutting production line. It should be noted that the simulation It is to establish the same system model as the real system in the computer, and avoid the cost caused by the real system experiment through the simulation experiment. Based on this, the simulation system principle of this embodiment is as follows figure 1 shown. Its structure is as figure 2 As shown, including a user interaction module 201 and a simulation module;

[0051] The user interaction module 201 is used to send the laser cutting production line configuration information and production order information input by the user to the simulation module, and output the production line planning simulation result information to the user after the simulation ends;

[0052] The ...

no. 2 example

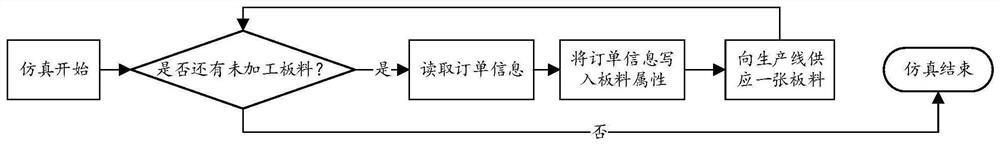

[0083] see Figure 12 , the present embodiment provides a simulation method for a laser cutting production line, including:

[0084] Receive the laser cutting production line configuration information and production order information input by the user, store the received laser cutting production line configuration information in the production line configuration table, and store the received production order information in the production planning task table; among them, the laser cutting production line Configuration information includes the model and planned location of each device in the laser cutting production line; production order information includes sheet metal processing time and marking time;

[0085] Read the parameter information of each equipment in the laser cutting production line in the preset data resource library, and generate the corresponding simulation model of the laser cutting production line according to the configuration information of the laser cuttin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com