Virtual assembly simulation method and system

A technology of virtual assembly and simulation method, which is applied in the field of virtual assembly simulation and system, and can solve the problems of matching size deviation of product parts and so on.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 2

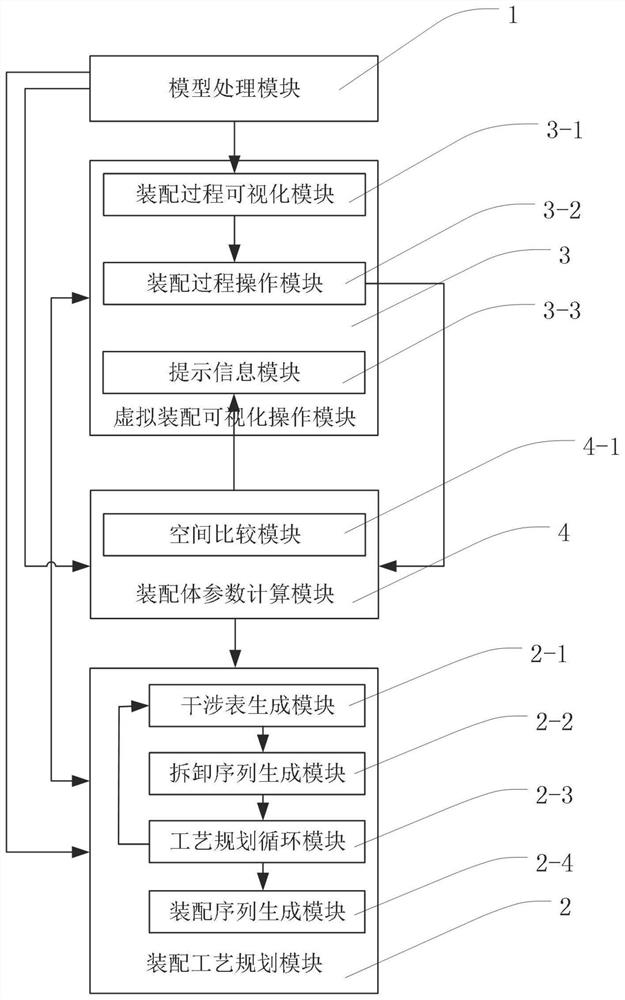

[0092] Specific embodiment two, a kind of virtual assembly simulation method of the present embodiment, namely the specific working steps of the virtual assembly simulation system are as follows:

[0093] Step 1. Enter the assembly training module 5 on the main interface, understand each component module of the virtual assembly simulation system through the structural diagram and description, and understand the interface logic relationship of the virtual assembly simulation system through the flow chart;

[0094] Step 2. Enter the model processing module 1, import the model of the designed product, set its scaling ratio, record the model information of each part, input its relevant parameters, such as quality characteristics, etc., and then generate collision boundaries for it, initialize the part model and the location of the tooling;

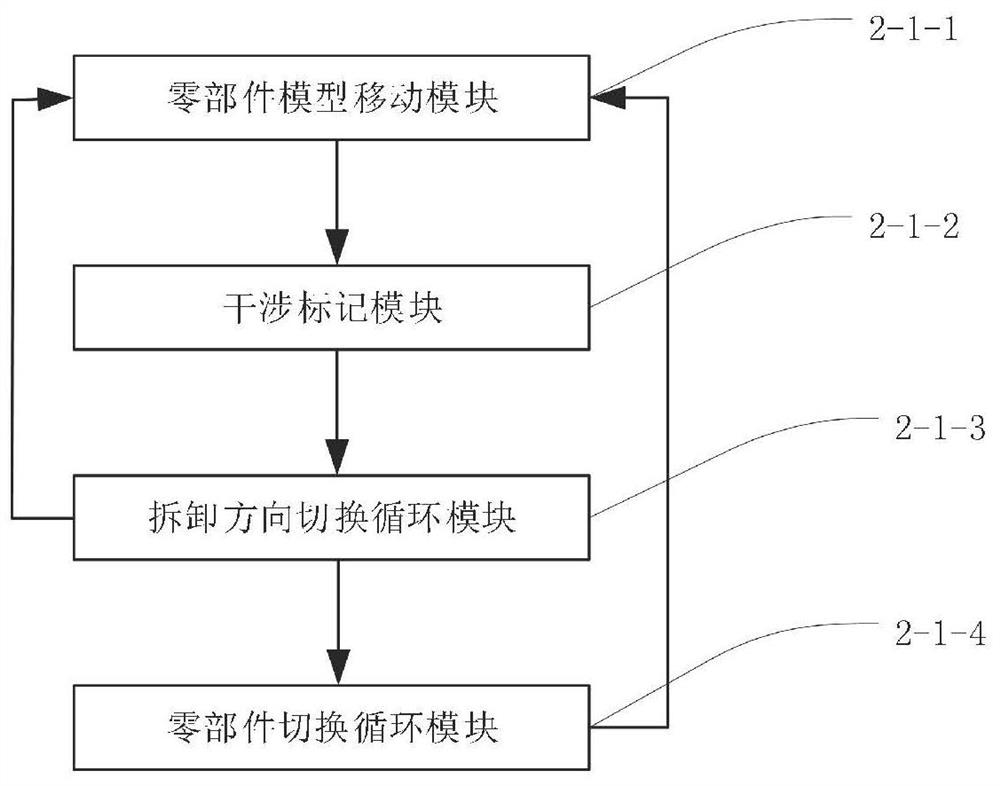

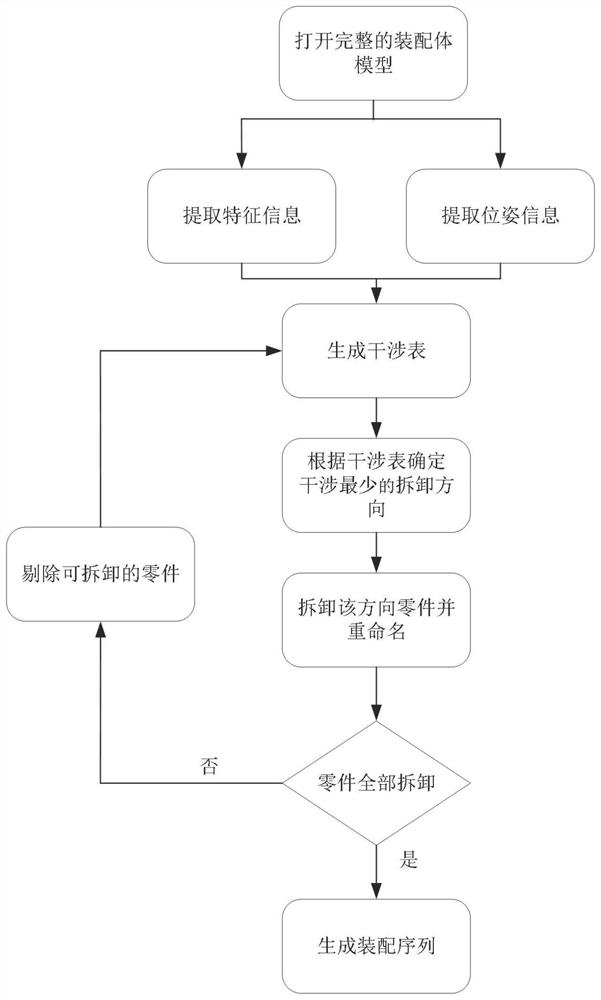

[0095] Step 3, enter the assembly process planning module 2, open the complete assembly model, and generate the assembly sequence by the syst...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com