Recycling application of 5 '-AMP and 5'-UMP in nucleotide chromatographic separation

A nucleotide and alkali technology, applied in chemical instruments and methods, preparation of sugar derivatives, sugar derivatives, etc., can solve the problems of large water consumption, affecting the yield of separation, and low purity of nucleotide products.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

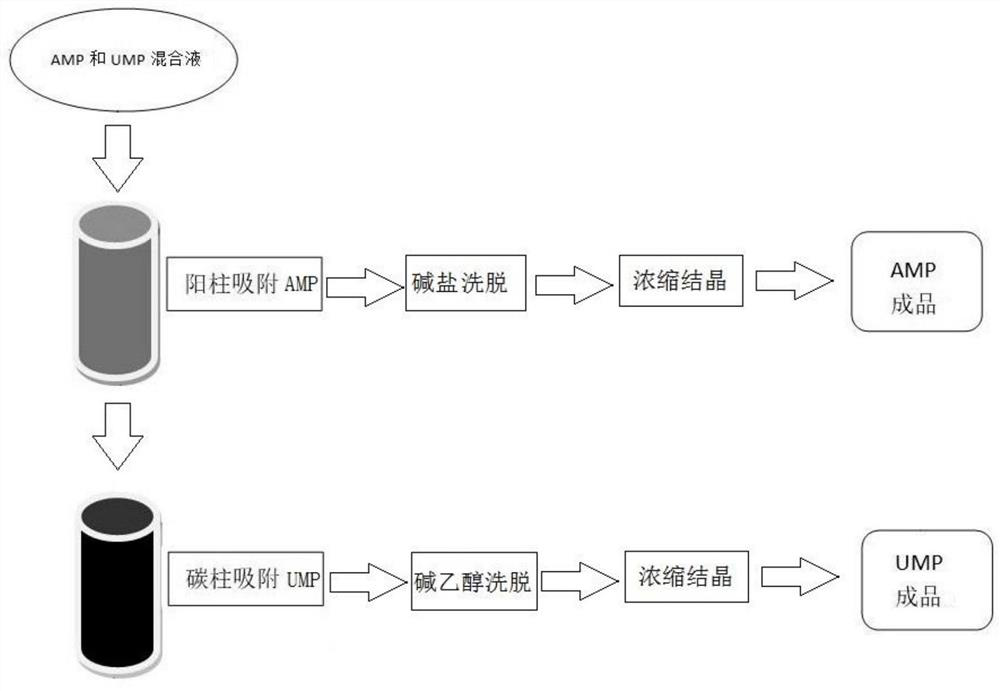

[0029] see Figure 1-2 , a recovery application of 5'-AMP and 5'-UMP in the chromatographic separation of nucleotides, comprising the following steps:

[0030] S1. Regeneration of cation resin: regenerate the cation resin with alkali and acid, wash with water to pH=3.0-4.0, wash off the impurities on the resin, charge the resin, and set aside;

[0031] S2, AMP, UMP mixed sample loading: Dilute the mixture of AMP and UMP to a concentration of 20-30g / L, adjust the pH=2.0-2.5, load the sample, AMP is adsorbed by the positive column, and UMP flows out directly to the carbon column without being adsorbed collection and adsorption;

[0032] S3. Washing with water: After loading the samples, AMP and UMP were washed with 4 times the column volume respectively;

[0033] S4. Elution: AMP is eluted with 2% NaCl; UMP is eluted with alkali ethanol;

[0034] S5. Concentrated crystallization: the eluted AMP and UMP are concentrated and crystallized to obtain finished AMP and UMP.

Embodiment 2

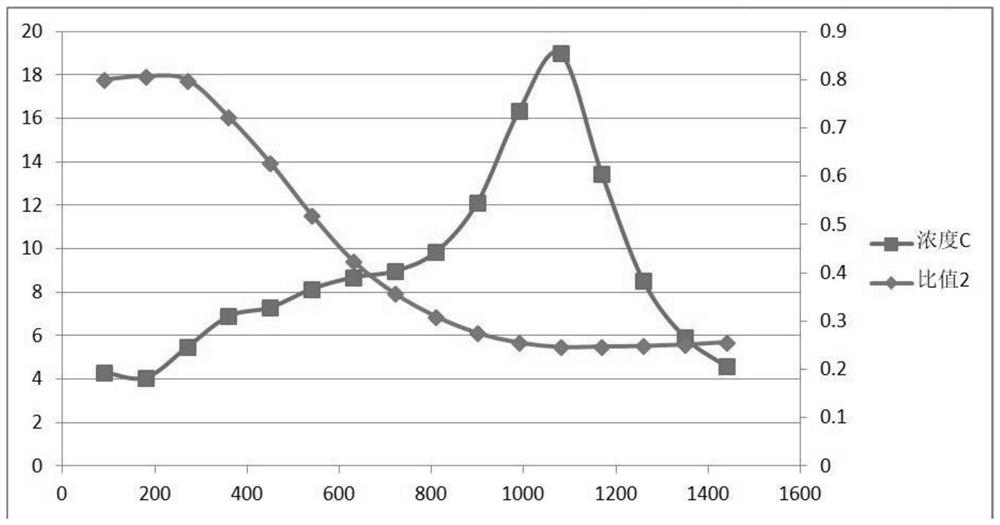

[0036] see figure 1 , 3 , a recovery application of 5'-AMP and 5'-UMP in the chromatographic separation of nucleotides, comprising the following steps:

[0037] S1. Regeneration of cation resin: regenerate the cation resin with alkali and acid, wash with water to pH=3.0-4.0, wash off the impurities on the resin, charge the resin, and set aside;

[0038] S2, AMP, UMP mixed sample loading: Dilute the mixture of AMP and UMP to a concentration of 20-30g / L, adjust the pH=2.0-2.5, load the sample, AMP is adsorbed by the positive column, and UMP flows out directly to the carbon column without being adsorbed collection and adsorption;

[0039] S3. Washing with water: After loading the samples, AMP and UMP were washed with 4 times the column volume respectively;

[0040] S4. Elution: AMP is eluted with 3% NaCl; UMP is eluted with alkali ethanol;

[0041] S5. Concentrated crystallization: the eluted AMP and UMP are concentrated and crystallized to obtain finished AMP and UMP.

Embodiment 3

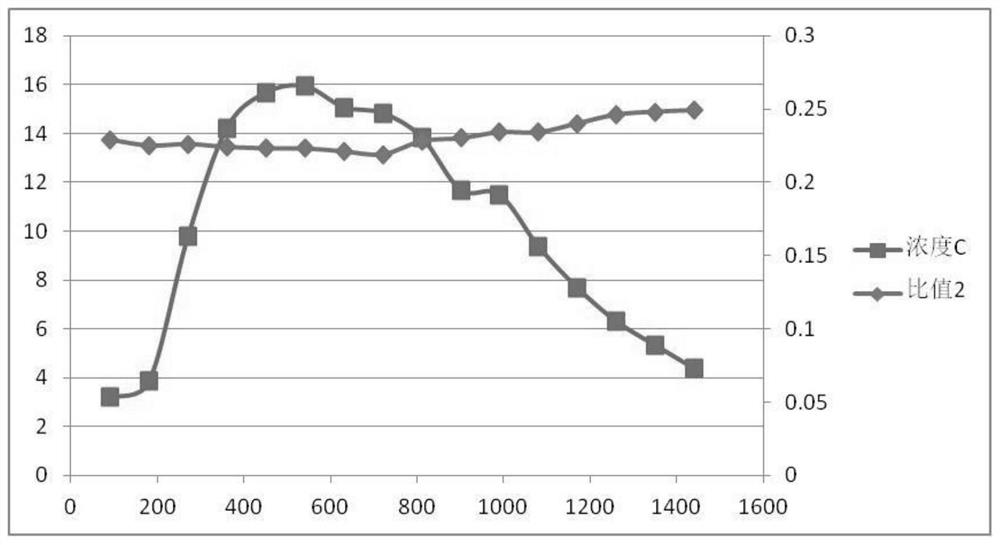

[0043] see figure 1 , 4 , a recovery application of 5'-AMP and 5'-UMP in the chromatographic separation of nucleotides, comprising the following steps:

[0044] S1. Regeneration of cation resin: regenerate the cation resin with alkali and acid, wash with water to pH=3.0-4.0, wash off the impurities on the resin, charge the resin, and set aside;

[0045] S2, AMP, UMP mixed sample loading: Dilute the mixture of AMP and UMP to a concentration of 20-30g / L, adjust the pH=2.0-2.5, load the sample, AMP is adsorbed by the positive column, and UMP flows out directly to the carbon column without being adsorbed collection and adsorption;

[0046] S3. Washing with water: After loading the samples, AMP and UMP were washed with 4 times the column volume respectively;

[0047] S4. Elution: AMP is eluted with 4% NaCl; UMP is eluted with alkali ethanol;

[0048] S5. Concentrated crystallization: the eluted AMP and UMP are concentrated and crystallized to obtain finished AMP and UMP.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com