Preparation method of high-transmittance anti-skid spot brick and high-transmittance anti-skid spot brick

A non-slip and speckle technology, applied in the field of ceramic tiles, can solve the problems of the glaze layer of speckled tiles being too thick, difficult to achieve high permeability, and the influence of speckle transparency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

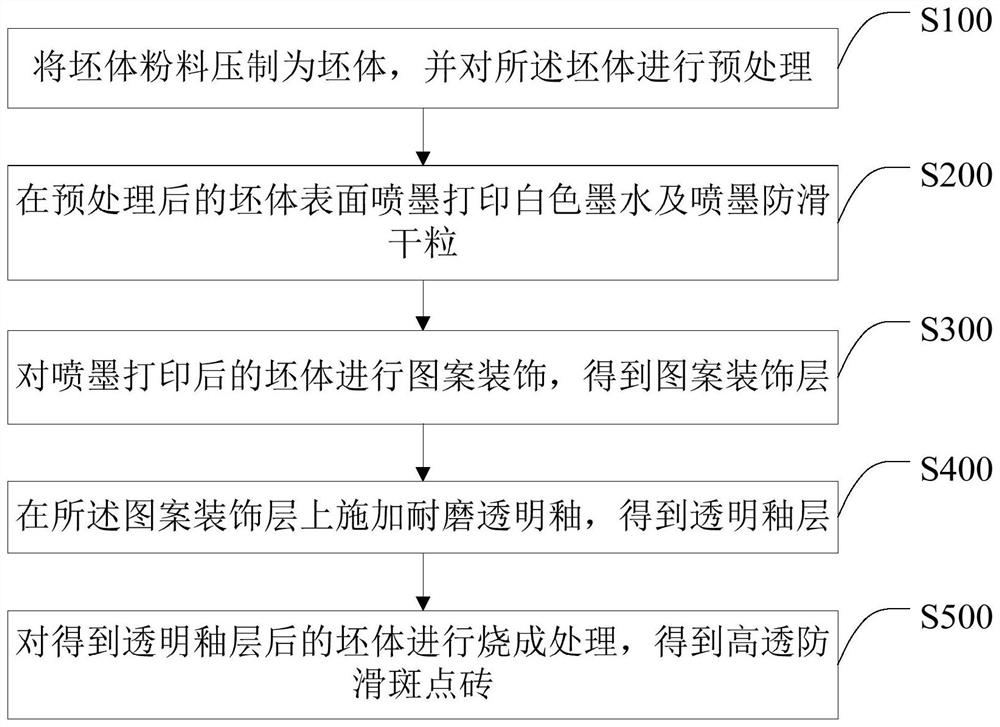

[0038] See figure 1 , figure 1 It is a flow chart of the preparation method of the high-transparency anti-skid spotted brick in the present invention. Such as figure 1 As shown, the preparation method of the high-transparency anti-skid spot brick described in the embodiment of the present invention comprises the following steps:

[0039] Step S100, pressing the green body powder into a green body, and performing pretreatment on the green body.

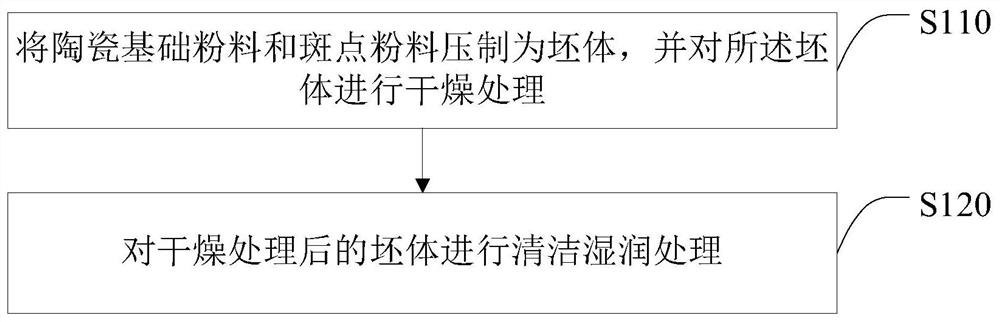

[0040] In an implementation manner, the green body powder includes ceramic base powder and speckle powder. see figure 2 , the step S100 specifically includes:

[0041] Step S110, pressing the ceramic base powder and spot powder into a green body, and drying the green body;

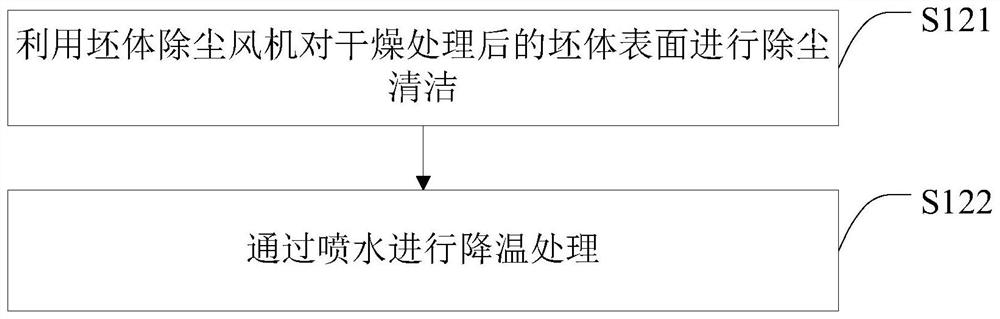

[0042] Step S120, performing cleaning and wetting treatment on the dried green body.

[0043] Specifically, the green body powder is composed of ceramic base powder and spot powder, the particle size of the ceramic base powder is 0.3-0.6 mm, and the chemica...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com