Garment fabric production, conveying and winding machine

A technology of winding machine and fabric, which is applied in the field of clothing fabric winding, which can solve the problems of affecting the cleanliness of clothing fabrics, the inability to ensure the flatness of clothing fabrics, and loose clothing fabrics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The embodiments of the present invention will be described in detail below with reference to the accompanying drawings, but the present invention can be implemented in many different ways defined and covered by the claims.

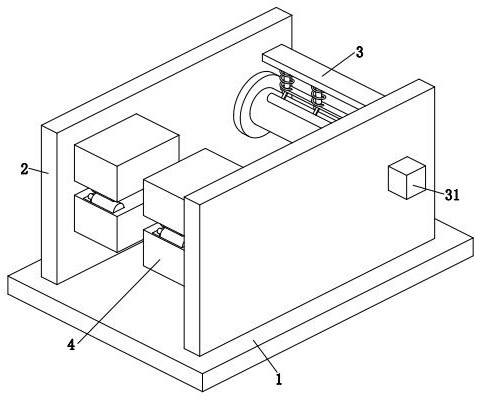

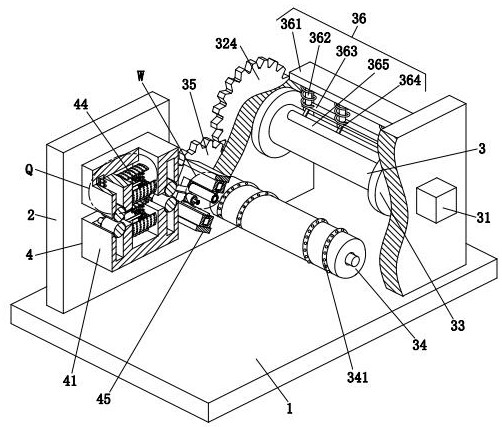

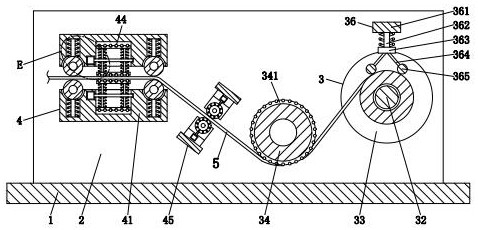

[0033] refer to figure 1 , figure 2 , image 3 , a conveyor and winding machine for garment fabric production, comprising a workbench 1, a support plate 2, a winding unit 3 and a flattening unit 4, the upper end of the workbench 1 is fixedly fixed with a support plate 2 front and back, and the right side of the opposite end of the support plate 2 A winding unit 3 is arranged on one side, and a leveling unit 4 is installed on the left side of the opposite end of the support plate 2 .

[0034] refer to figure 2 , image 3 , Figure 4 , the winding unit 3 includes a No. 1 motor 31, a linkage shaft 32, a winding roller 33, a positioning roller 34, an execution gear 35 and a tensioning assembly 36, wherein: No. 1 motor 31 is fixedly arranged on th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com