Automatic lathe capable of taking materials conveniently

A technology of a centering machine and a feeding mechanism, which is applied in the field of a centering machine that is convenient for retrieving materials, and can solve problems such as movement and unfavorable connection processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

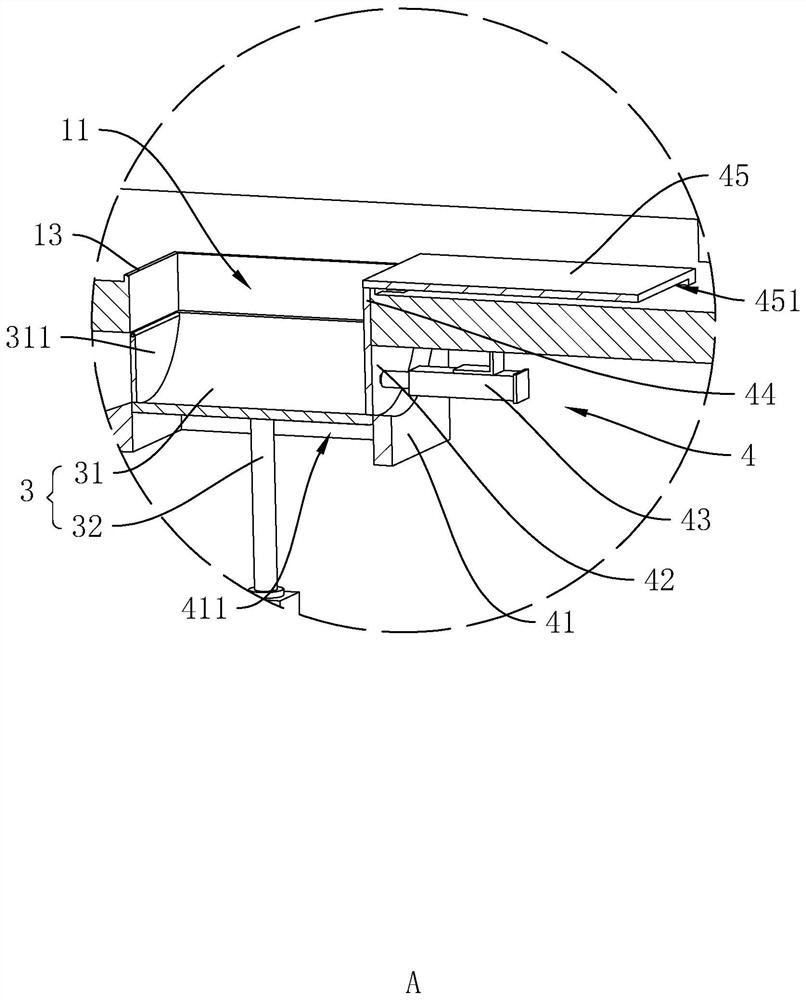

[0033] The following is attached Figure 1-5 The application is described in further detail.

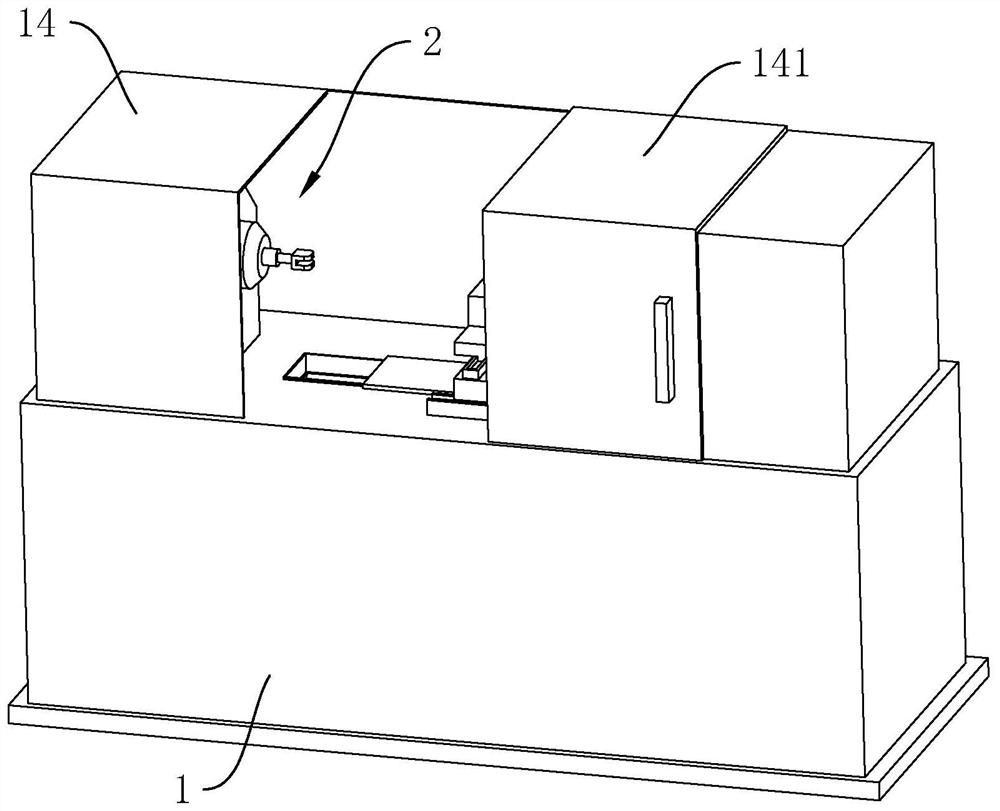

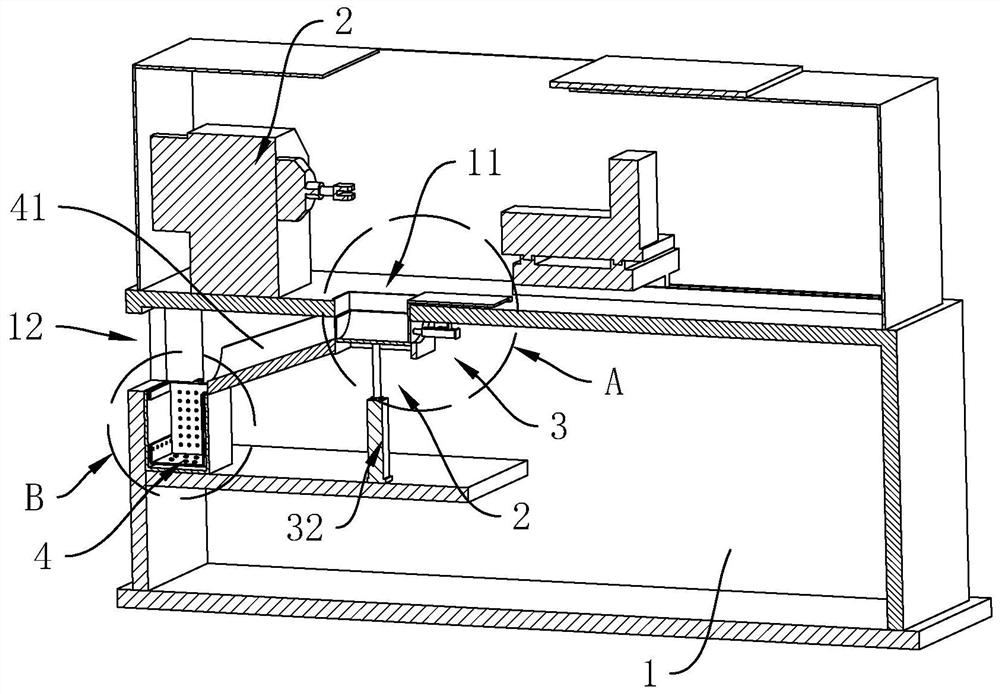

[0034] The embodiment of the present application discloses a centering machine that is convenient for taking out materials. refer to figure 1 and figure 2The centering machine includes a machine tool 1 and a clamping mechanism 2. The clamping mechanism 2 is installed on the top of the machine tool 1 for clamping the workpiece to be processed. around. One side of the protective cover 14 is equipped with a sliding door 141, and the staff can enter the protective cover 14 through the sliding door 141 to operate the equipment; The workpiece processed on the clamping mechanism 2 is picked up to the bottom of the machine tool 1, and then the workpiece is transported to the receiving mechanism 5 through the feeding mechanism 4 for centralized collection of the workpiece, without the need for staff to enter the protective cover 14 to take materials.

[0035] refer to figure 2 and i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com