Down jacket and production system thereof

A production system and down jacket technology, applied in the field of garment production, can solve the problems of affecting the compression work, down affecting the compression work, unable to guarantee the overall shape of the down jacket, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

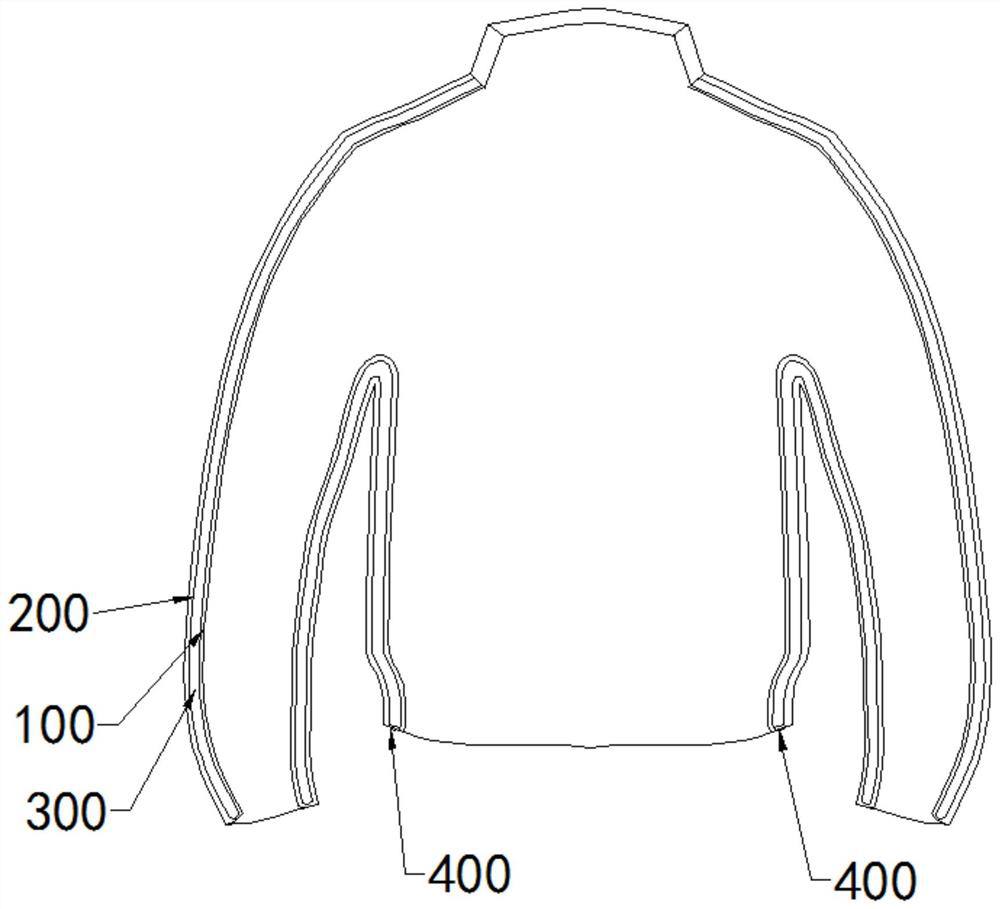

[0041] Such as figure 1 As shown, the present invention discloses a down jacket. In a specific embodiment of the invention, it includes a front panel, a rear panel, sleeves and a collar, and the front panel, the rear panel, the sleeves and the collar are sewed together to form a down jacket body , the front panel, the rear panel, and the sleeves are all provided with a down liner, and the collar is filled with down; the down liner includes an inner layer 100 and an outer layer 200, and the inner layer and the outer layer An inflatable cavity 300 is arranged between them, the lower end of the rear panel is provided with a valve body 400 communicating with the inflatable cavity 300, the inflatable cavity of the rear panel communicates with the inflatable cavity of the front panel and the inflatable cavity of the sleeves, the front panel, The rear panel and the end of the sleeve facing the inflatable cavity are provided with mesh cloth, which facilitates the passage of gas; in th...

Embodiment 2

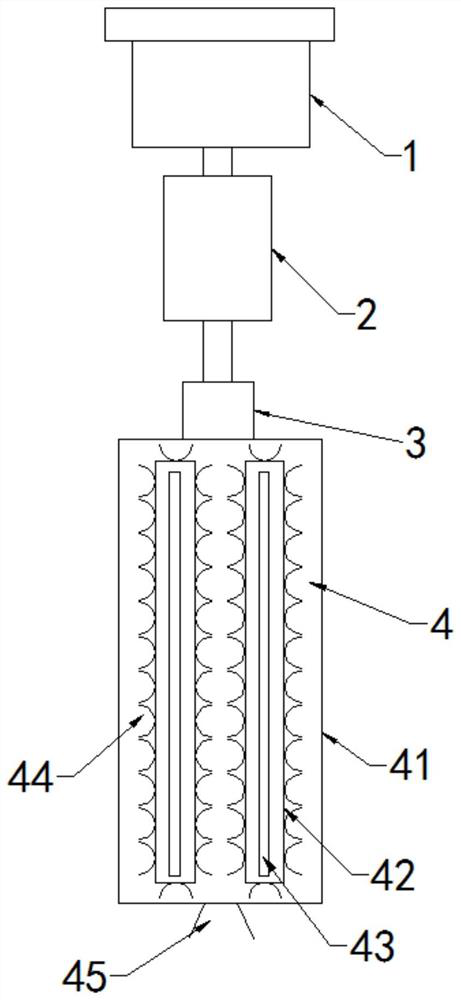

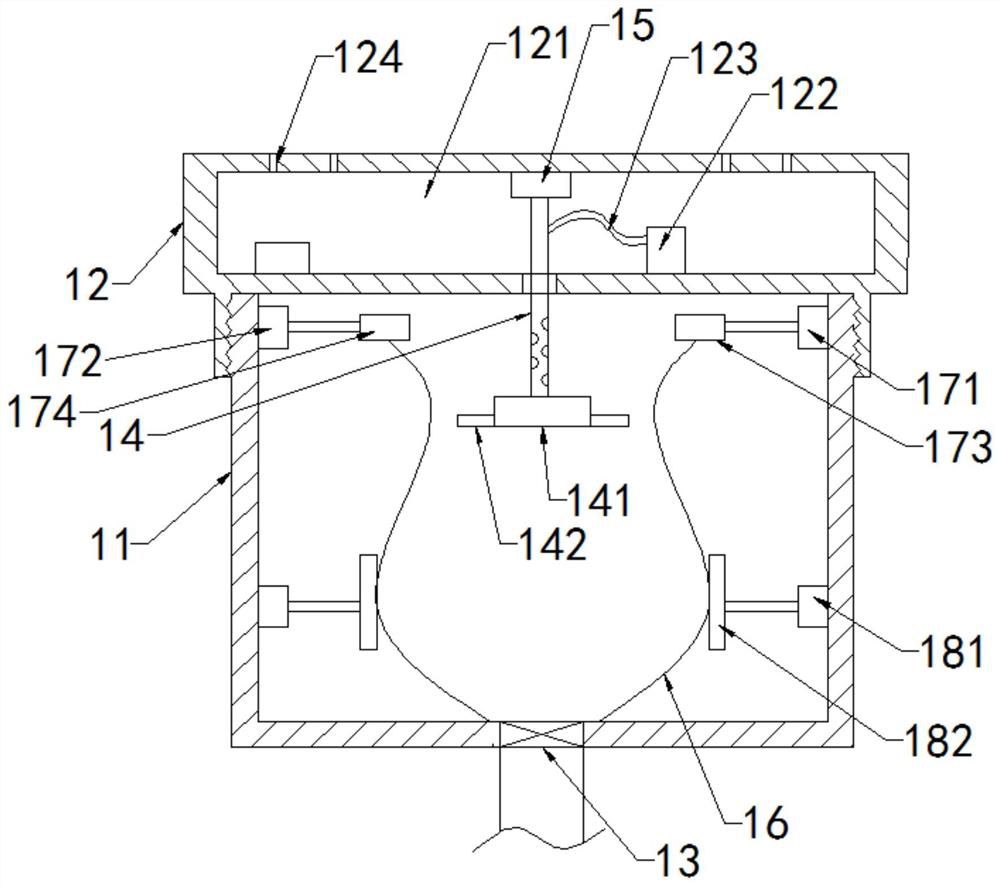

[0044] Such as figure 2 As shown, the present invention discloses a production system for down jackets. In a specific embodiment of the present invention, it includes a cutting unit for cutting the outer fabric according to the pattern, and cutting it into front panels, rear panels, sleeves and jackets. collar; a pretreatment unit, including a cleaning device, for cleaning the down to be treated; a treatment tank, for soaking and heating the cleaned down in alkaline water; an air-drying device, for air-drying the heated down for standby; The down ball preparation unit includes a compression device 1 for compressing the down; a shaping device 2 for wrapping and shaping the down with a water-soluble adhesive; a cutting device for cutting the compressed down into down balls; a drying device 4 for The shaped down balls are dried; the stuffing unit is used to evenly stuff the prepared down balls into the inner and outer layers of the down liner according to the number; the sewing ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com