Caramel color and preparation method thereof

A caramel color and color rate technology, applied in the field of caramel color and its preparation, can solve the problems of limited application range, difficulty in meeting high color rate and high red index at the same time, poor salt resistance stability, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

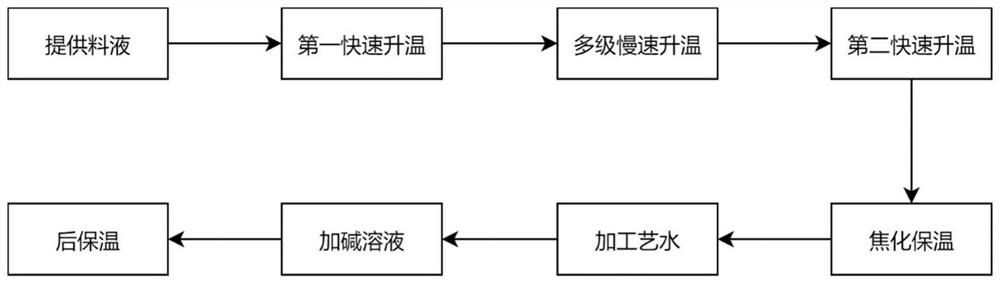

Method used

Image

Examples

Embodiment 1

[0079] Mix the sulfite and ammonium salt with the glucose syrup evenly. Sulfite and ammonium salt are based on 8% and 5% of the dry matter content of glucose syrup.

[0080] Then the mixed material is pumped into the reaction kettle through a high-pressure pump, the positive pressure in the reaction kettle is controlled to be (0.01±0.005) MPa, and the stirring speed is 20-30r / min.

[0081] Carry out the first rapid heating of the material, from room temperature to 115°C, which takes 30 minutes.

[0082] The material is heated up slowly in multiple stages, and the specific temperature control method is as follows:

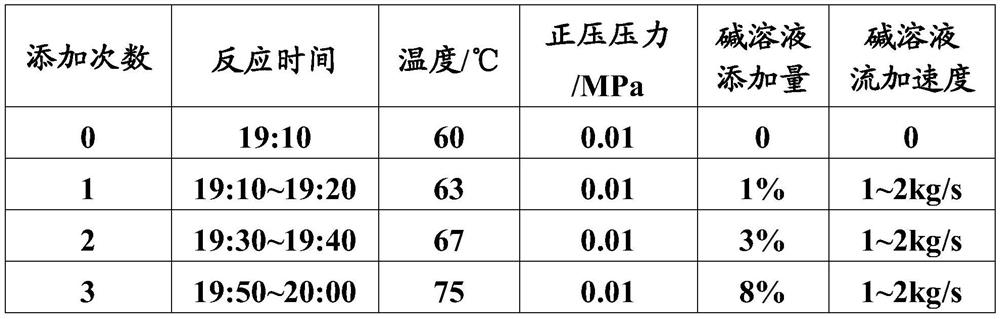

[0083] Table 1

[0084] Temperature control times Reaction time temperature / ℃ Positive pressure / MPa 0 14:30 115 0.01±0.005 1 14:30~15:00 115→120 0.01±0.005 2 15:00~15:20 120→125 0.01±0.005 3 15:20~15:30 125→130 0.01±0.005

[0085] After the multi-stage slow temperature rise is completed, start the second rapid tempe...

Embodiment 2

[0096] Mix the sulfite and ammonium salt with the glucose syrup evenly. Sulfite and ammonium salt are based on 10% and 6% of the dry matter content of glucose syrup.

[0097] Then the mixed material is pumped into the reaction kettle through a high-pressure pump, the positive pressure in the reaction kettle is controlled to be (0.02±0.005) MPa, and the stirring speed is 20-30r / min.

[0098] Carry out the first rapid heating of the material, from room temperature to 115°C, which takes 30 minutes.

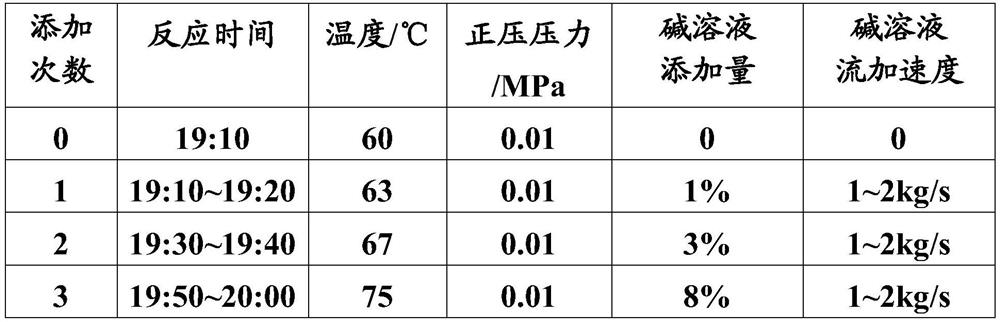

[0099] The material is heated up slowly in multiple stages, and the specific temperature control method is as follows:

[0100] Table 4

[0101] Temperature control times Reaction time temperature / ℃ Positive pressure / MPa 0 14:30 115 0.02±0.005 1 14:30~15:00 115→120 0.02±0.005 2 15:00~15:20 120→125 0.02±0.005 3 15:20~15:30 125→130 0.02±0.005

[0102] After the multi-stage slow temperature rise, start the second rapid temperature rise ...

Embodiment 3

[0112] Mix the sulfite and ammonium salt with the glucose syrup evenly. Sulfite and ammonium salt are based on 15% and 7.5% of the dry matter content of glucose syrup.

[0113] Then the mixed material is pumped into the reaction kettle through a high-pressure pump, the positive pressure in the reaction kettle is controlled to be (0.03±0.005) MPa, and the stirring speed is 20-30r / min.

[0114] Carry out the first rapid heating of the material, from room temperature to 115°C, which takes 30 minutes.

[0115] The material is heated up slowly in multiple stages, and the specific temperature control method is as follows:

[0116] Table 7

[0117] Temperature control times Reaction time temperature / ℃ Positive pressure / MPa 0 14:30 115 0.03±0.005 1 14:30~15:00 115→120 0.03±0.005 2 15:00~15:20 120→125 0.03±0.005 3 15:20~15:30 125→130 0.03±0.005

[0118] After the multi-stage slow temperature rise, start the second rapid temperature ris...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com