Permanent magnet motor assembling mould

A technology of permanent magnet motor and mould, applied in the field of machinery, can solve problems such as parts and insulation damage, affecting the quality of the motor, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

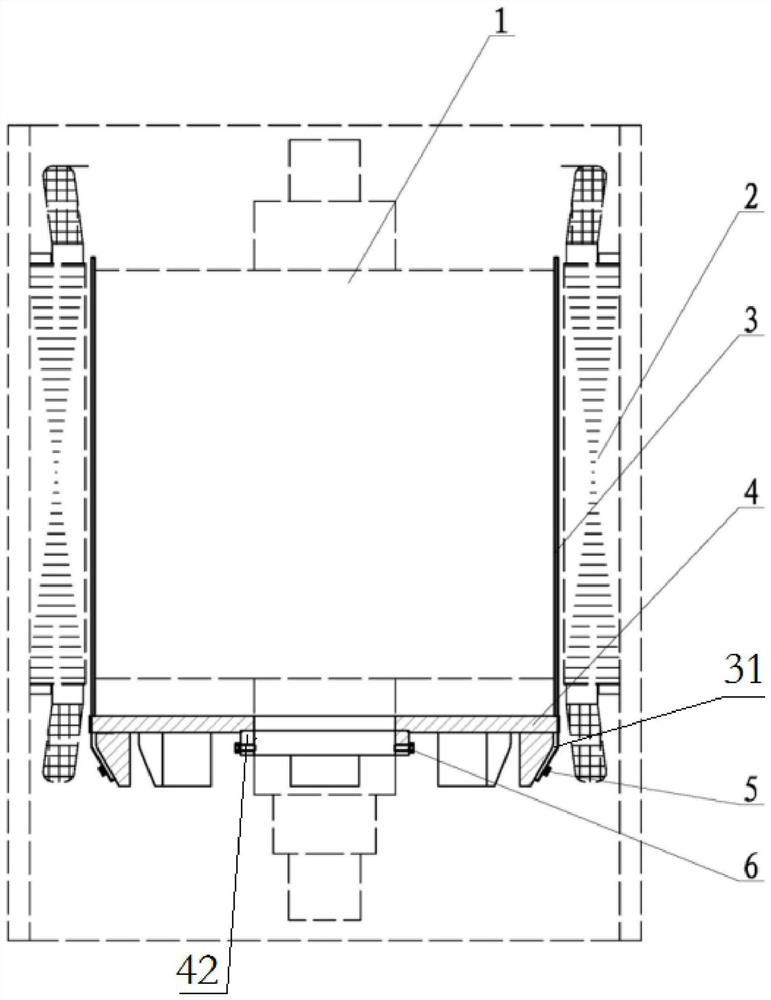

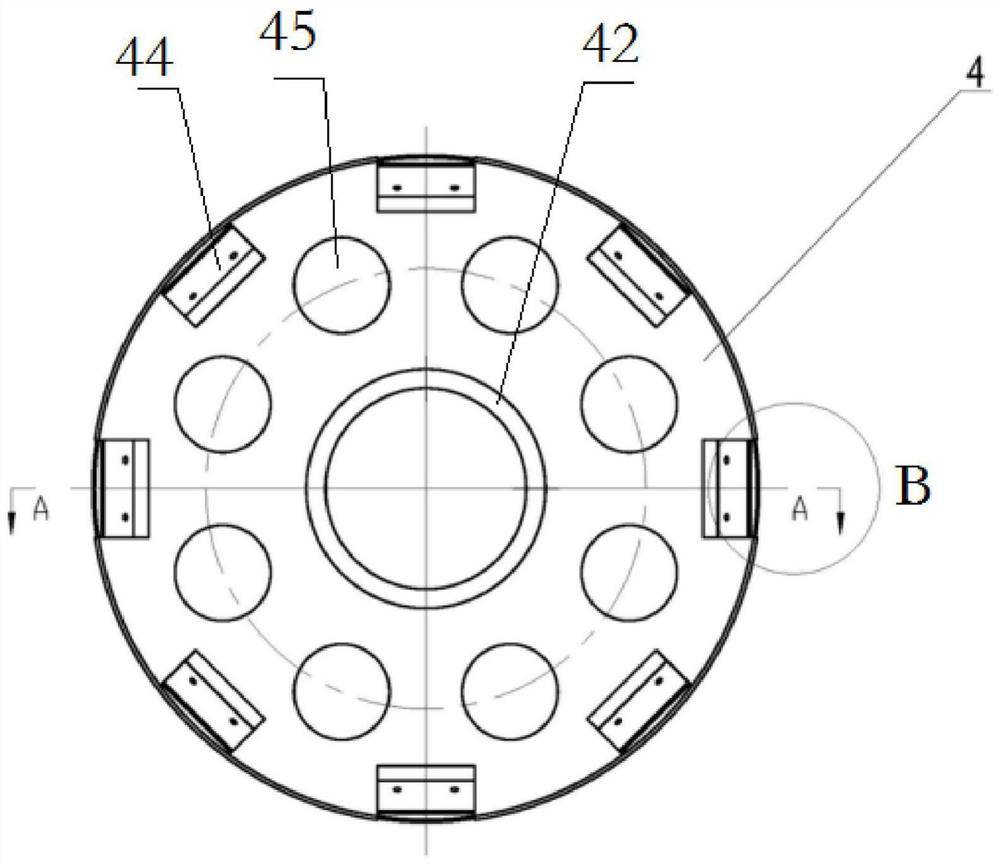

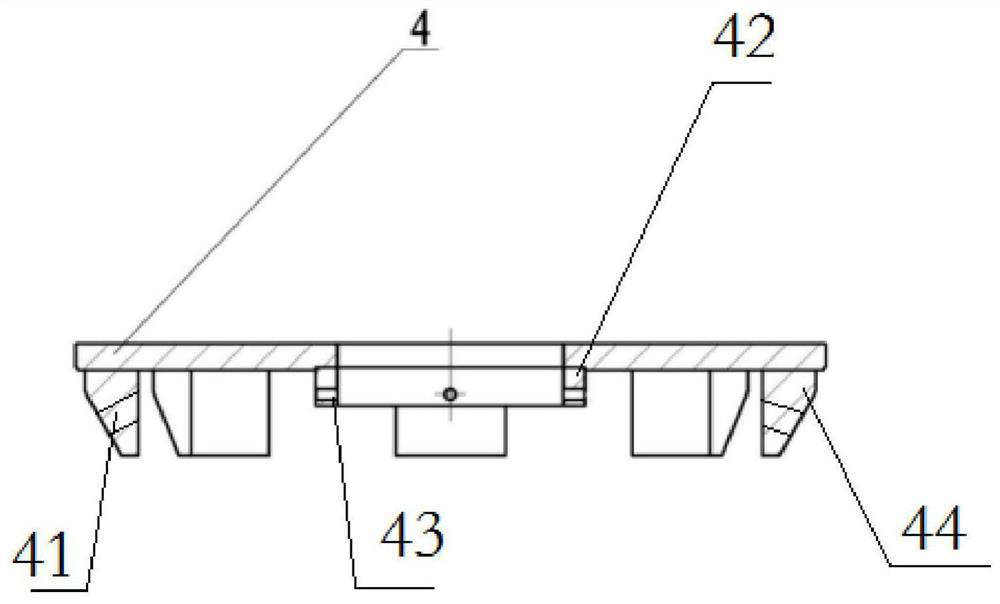

[0016] The present invention will be described in detail below in conjunction with the accompanying drawings. As shown in the figure, the present invention includes a disc-shaped base 4, the upper end of the base abuts against the axial end of the rotor 1, and the lower end of the base 4 is provided with a limit ring 42, so that A radial screw hole 43 is set on the limit ring 42, the front end of the main shaft of the rotor passes through the limit ring 42 and is locked by the first positioning screw 6 tightened on the limit ring; the outer ring of the lower end of the base is provided with multiple A positioning post 44, screw holes 41 are set on the positioning post, and through holes are set at the lower end of the magnetic separation strip 3, and the second positioning screw 5 is screwed on the positioning post 44 after passing through the through hole; the upper end of the magnetic separation strip Fit snugly on the outside of the rotor. When in use, in order to prevent t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com