Intelligent inspection system for transformer substation

An intelligent inspection and substation technology, applied in the field of substation inspection, can solve the problems of limited range of robot activities, low efficiency of substation inspection, and incapable equipment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

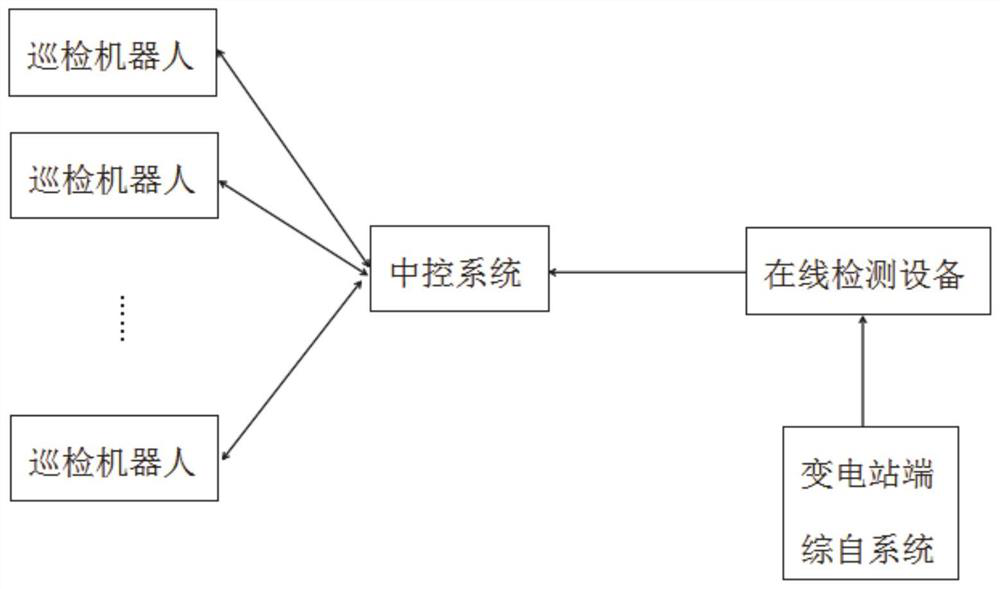

[0022] Such as Figure 1-2 As shown, a substation intelligent inspection system includes:

[0023] Central control system, multiple inspection robots and online monitoring equipment;

[0024] Among them, the online monitoring equipment is connected with the substation-side comprehensive self-system to obtain the remote signaling and telemetry data of the substation-side comprehensive self-system in real time, such as substation monitoring video, environmental monitoring data, fire alarm signal, security alarm signal, lighting power control signal, etc. And feed back the above data to the central control system in real time;

[0025] The inspection robot includes a data acquisition device, a robot data processing device, a robot driving device and a robot communication device; among them,

[0026] The data acquisition device is used to collect visible light photos, infrared spectra, equipment health status information and environmental information of the substation equipment;...

Embodiment 2

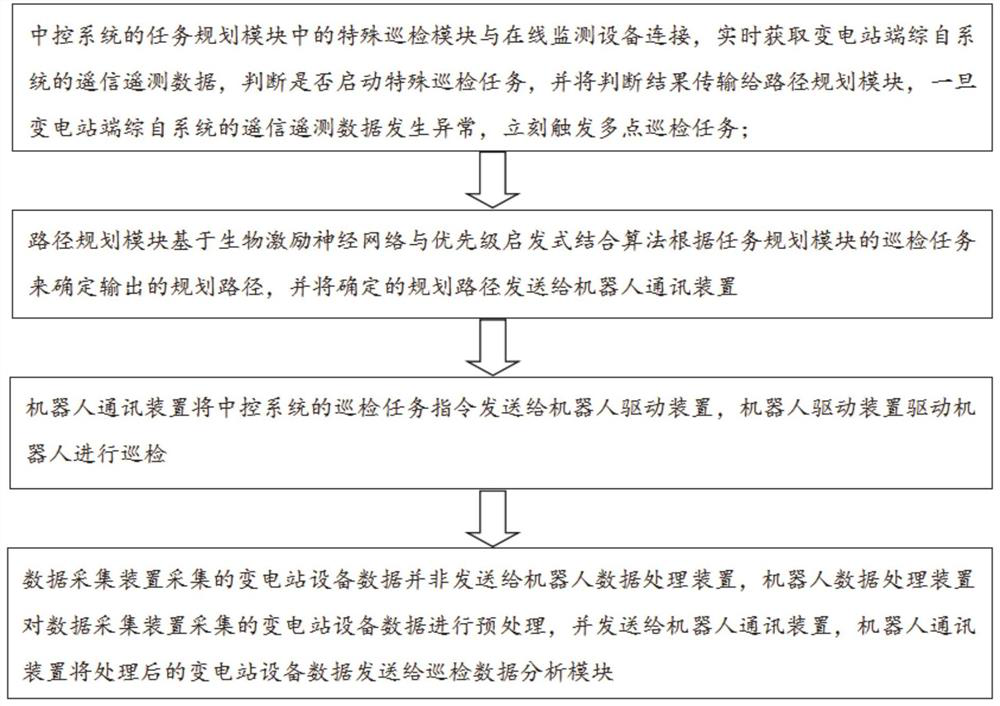

[0070] Such as image 3 The present embodiment shown provides a working method of a substation intelligent inspection system, including:

[0071] Step 1: The special inspection module in the task planning module of the central control system is connected with the online monitoring equipment to obtain the remote signaling and telemetry data of the substation-side integrated self-system in real time, judge whether to start the special inspection task, and transmit the judgment result to the path In the planning module, once the remote signaling and telemetry data of the substation-side integrated self-system is abnormal, the multi-point inspection task will be triggered immediately;

[0072] Step 2: The path planning module determines the output planning path according to the inspection task of the task planning module based on the combination algorithm of the bio-inspired neural network and the priority heuristic, and sends the determined planning path to the robot communicatio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com