Double-end terminal pressing machine for wire harness

A terminal crimping machine and terminal crimping technology, which is applied in the direction of line/collector components, electrical components, circuits, etc., can solve the problems of low degree of automation, cumbersome crimping processing operations, and low processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

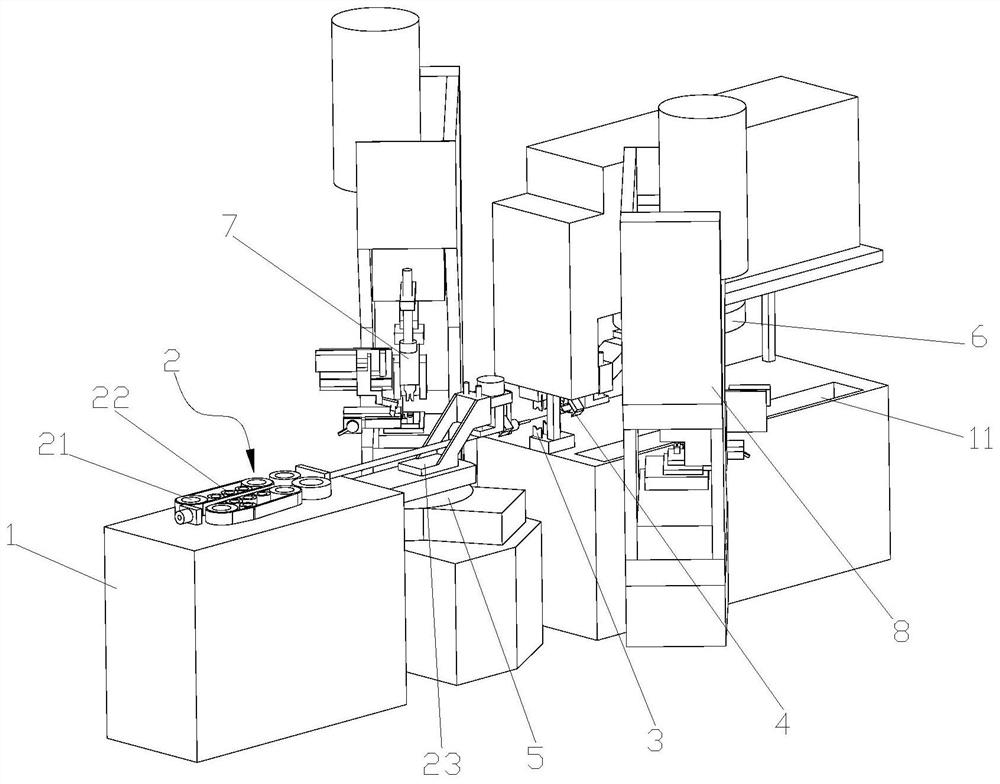

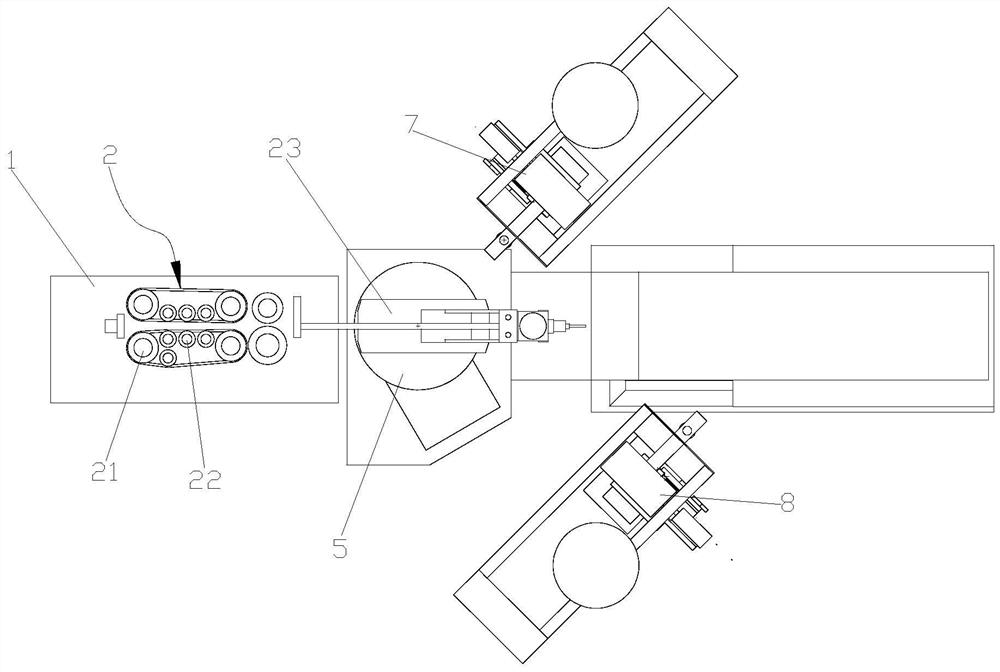

[0048] Such as Figure 1-Figure 7As shown, a double-head terminal crimping machine for wire harnesses described in the present disclosure includes a frame 1 and a wire harness module 2 , a cutting module 3 , a clamping module 4 , a first swing module 5 , and The second swing module 6, the first crimping terminal module 7, the second crimping terminal module 8 and the control module.

[0049] Rack 1 is usually in the shape of a long platform.

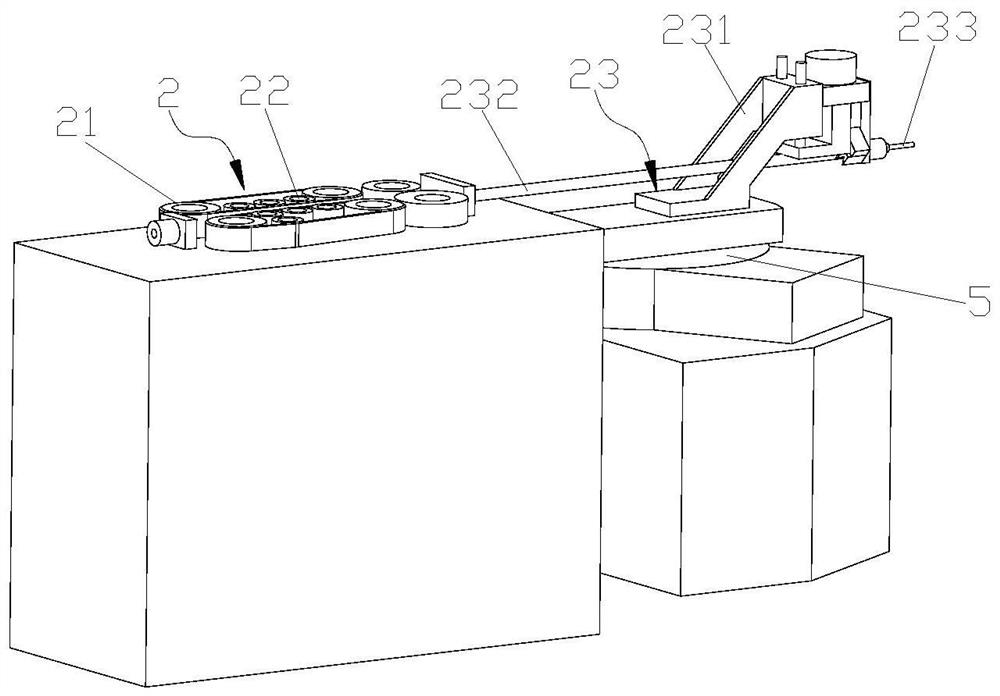

[0050] The wire harness feeding module 2 is used for feeding the wire harness along a straight path, specifically, along the length direction of the rack 1 . The wire harness module 2 includes a first driver 21 for driving the wire harness to move, a guide mechanism 22 for guiding the wire harness to move along a linear path, and a wire harness seat 23 for the wire harness to pass through. The wire harness seat 23 is arranged at the end of the wire harness conveying path. front section.

[0051] The cutting module 3 is arranged in the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com