Lithium ion battery low-voltage selection method

A lithium-ion battery and battery technology, which is applied in the direction of measuring electricity, measuring electrical variables, measuring devices, etc., can solve the problems of low-voltage battery leakage and misjudgment of lithium-ion batteries, and achieves low leakage and misjudgment rate, strict standards, and reduced leakage. The effects of judgment and misjudgment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

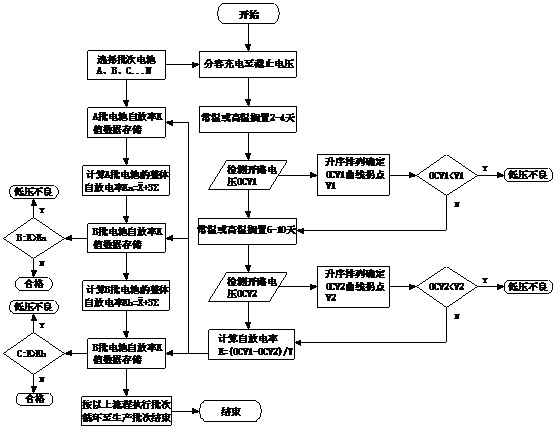

[0032] like Figure 1-7 As shown, a lithium-ion battery low-voltage selection method includes a low-voltage selection process and a low-voltage selection standard, and the low-voltage selection process includes the following steps:

[0033] Step 1): Select A, B, and C batches of batteries according to time (batch / 24H);

[0034] Step 2): Charge the battery to full charge at a constant current and constant voltage of 0.5C, cut off the current at 0.03C, discharge to empty at a constant current of 0.5C, cycle the above process twice, and the second time is 0.5C Current constant current constant voltage charge to half charge 3750mV, cut-off current 0.03C;

[0035] Step 3): Put the battery charged in the above steps at room temperature for 2 days;

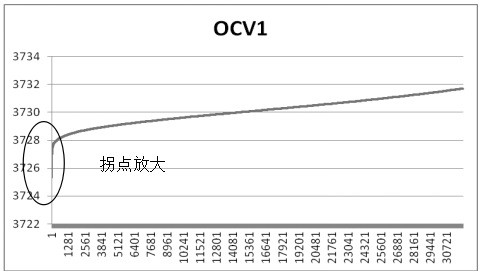

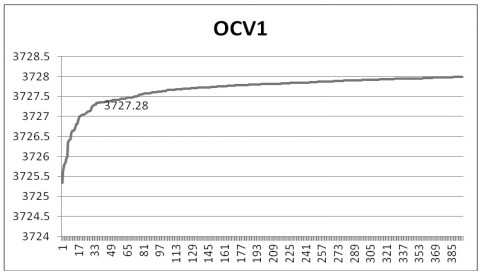

[0036] Step 4): Test the open circuit voltage OCV1 of the battery after the above steps are put on hold;

[0037] Step 5): Continue to store the battery after measuring OCV1 at room temperature for 7 days;

[0038] Step 6): Test the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com