Mid-infrared-transmitting and heat-insulating packaging mid-infrared heat supply and physiotherapy roller shutter

A technology of thermal insulation and infrared heat, applied in the fields of therapy, phototherapy, radiation therapy, etc., can solve the problems of insufficient mechanical strength of sandwich components to protect, curing of thinking, burns of skin contact screen, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0087] In some embodiments of the present invention, the preparation method of the mid-infrared emitting roller blind described in the present invention comprises:

[0088] (1) Electroporation mid-infrared emitting film layer is prepared by using nano-carbon plastic compound: the plastic is dispersed in an organic solvent to form the first mixed solution, and then the nano-carbon is dispersed in the above-mentioned first mixed solution to form the second mixed solution; The electrotransfer mid-infrared emitting film layer is prepared by a slurry film forming process;

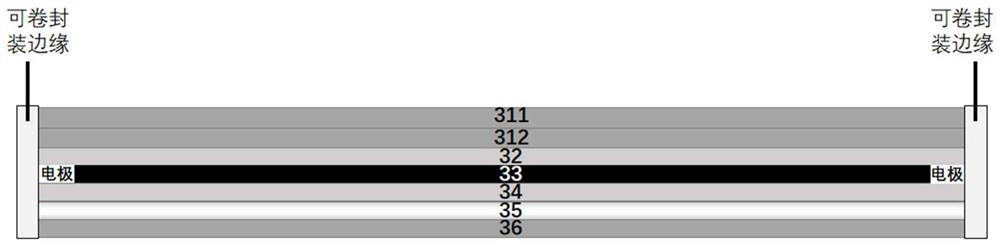

[0089] (2) The first electrical insulation layer and the second electrical insulation layer are stacked on the upper and lower sides of the electrotransfer mid-infrared emission film layer respectively to obtain the first electrical insulation layer, the electrotransfer mid-infrared emission film layer and the second electrical insulation layer. A laminated structure of layers, wherein the electro-converted mid-...

Embodiment

[0099] Some specific embodiments are described in detail below. It should be noted that the following content is only an illustration or description of the application of the principle of the present invention. Many modifications can be made and other components, methods and systems can be substituted without departing from the existing principles and scope. Additional requirements cover these modifications and schemes. Thus, while the invention has been described in detail above, the following examples provide further details of what is presently considered to be the most feasible solution.

no. 1 example

[0101] Preparation method and performance test of mid-infrared emitting roller blind made of porous polyethylene mid-infrared thermal insulation layer structure

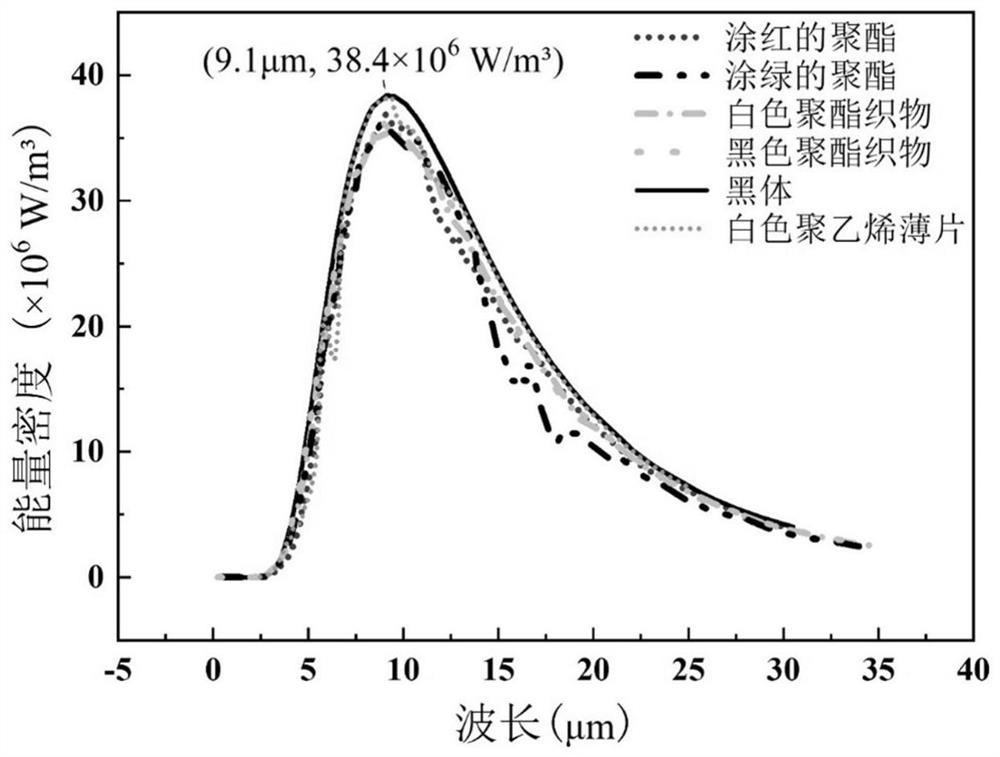

[0102] In this preferred embodiment of the invention, a high performance mid-infrared emitting roller blind is produced. First, using coal-based nano-carbon with high conductivity as ink, the mid-infrared emitting film of nano-carbon composite was prepared by standard film casting process. The sheet resistance of the obtained film is 26±2Ω / □ and the thickness is 80±2μm, and the size is 2500cm 2 electric heating film. Under the applied voltage of 35V, the rated power of the mid-infrared emitting roller blind is 150W and 0.060W / cm respectively 2 . The structure of the porous polyethylene transparent mid-infrared thermal insulation layer is composed of porous polyethylene whose thermal insulation effect is close to that of a 3mm air layer. The user-facing top layer is composed of colored polyethylene with nearly 100...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com