Preparation method of comb-shaped organic silicon modified waterborne polyurethane, obtained polyurethane and application of comb-shaped organic silicon modified waterborne polyurethane

A technology of water-based polyurethane and silicone, which is applied in the direction of improved hand-feeling fibers, wear-resistant fibers, textiles and papermaking, etc. It can solve the problems of affecting the appearance, reducing the hydrophilicity of fabrics, and poor hygroscopicity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

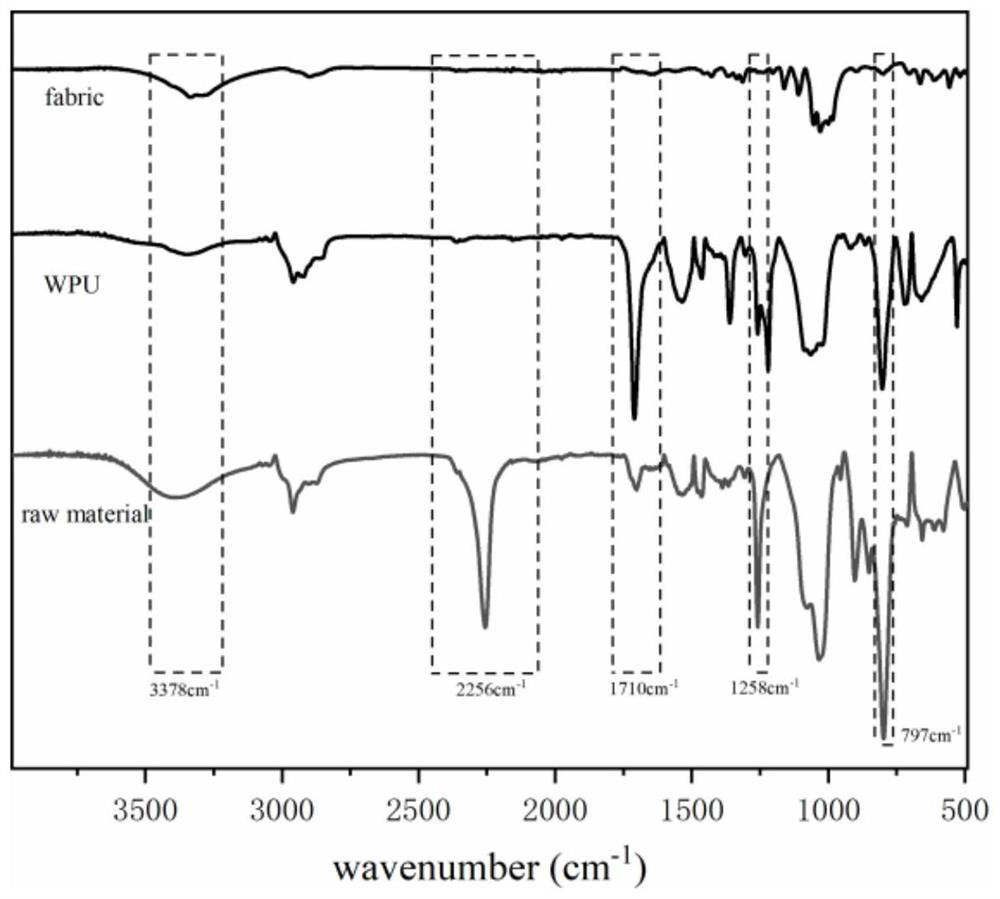

[0027] (1) Put polyether diol N120 with a molecular weight of 1000, hydroxyl silicone oil with a molecular weight of 400, and 2,2-dimethylolpropionic acid in a vacuum drying oven and heat at 80°C for 11 h to remove the moisture in the reaction raw materials ; Use a vacuum tube type high-temperature sintering furnace to heat the 4A molecular sieve at 600 ° C for 6 h for activation, then put it in tetrahydrofuran to absorb water, and use it after one week of treatment.

[0028] (2) Use oil bath heating and mechanical stirring to build a reaction device. Add 0.8 mol of hydroxyl silicone oil 400 to a three-necked flask with a condenser tube, then add 2 mol of IPDI and 0.5 mol of tetrahydrofuran, and react at 70°C for 2 h. Hydroxyl silicone oil 400 was added dropwise using a constant pressure funnel at a rate of 2 drops / s.

[0029] (3) Then add 0.8 mol of 2,2-dimethylolpropionic acid as a chain extender, and at the same time add 2 drops of dibutyltin dilaurate as a catalyst, and us...

Embodiment 2

[0035] (1) Put polyether diol N120 with a molecular weight of 1000, hydroxyl silicone oil with a molecular weight of 400, and 2,2-dimethylolpropionic acid in a vacuum drying oven and heat at 85°C for 10 h to remove the moisture in the reaction raw materials ; Use a vacuum tube type high-temperature sintering furnace to heat the 4A molecular sieve at 650 ° C for 5 h for activation, then put it in tetrahydrofuran to absorb water, and use it after one week of treatment.

[0036] (2) Use oil bath heating and mechanical stirring to build a reaction device. Add 0.6 mol of hydroxyl silicone oil 400 to a three-necked flask with a condenser tube, then add 2 mol of IPDI and 0.6 mol of tetrahydrofuran, and react at 75°C for 3 h. Hydroxyl silicone oil 400 was added dropwise using a constant pressure funnel at a rate of 2 drops / s.

[0037] (3) Then add 1.6mol of 2,2-dimethylolpropionic acid as a chain extender, and at the same time add 3 drops of dibutyltin dilaurate as a catalyst, and use...

Embodiment 3

[0043] (1) Put polyether diol N120 with a molecular weight of 1000, hydroxyl silicone oil with a molecular weight of 1000 and 2,2-dimethylol propionic acid in a vacuum drying oven and heat at 85°C for 10 h to remove the moisture in the reaction raw materials ; Use a vacuum tube type high-temperature sintering furnace to heat the 4A molecular sieve at 600 ° C for 5 h for activation, then put it in tetrahydrofuran to absorb water, and use it after one week of treatment.

[0044] (2) Use oil bath heating and mechanical stirring to build a reaction device. Add 0.6 mol of hydroxyl silicone oil 400 to a three-necked flask with a condenser tube, then add 2 mol of IPDI and 0.5 mol of tetrahydrofuran, and react at 75°C for 3 h. Hydroxyl silicone oil 400 was added dropwise using a constant pressure funnel at a rate of 2 drops / s.

[0045] (3) Then add 0.8 mol of 2,2-dimethylolpropionic acid as a chain extender, and at the same time add 2 drops of dibutyltin dilaurate as a catalyst, and u...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com