Three-dimensional braiding machine discretization core mold system based on variable-curvature special-shaped revolving body

A variable curvature and discretization technology, applied in the field of three-dimensional braiding machines, can solve the problems of complex shape of the core mold

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

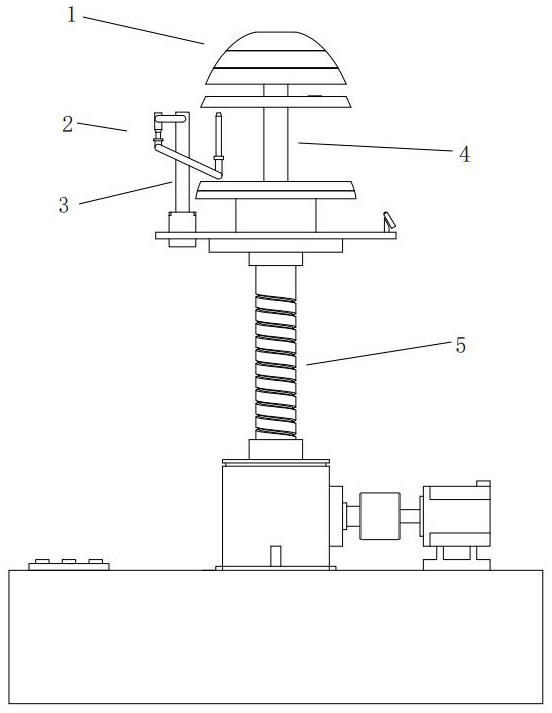

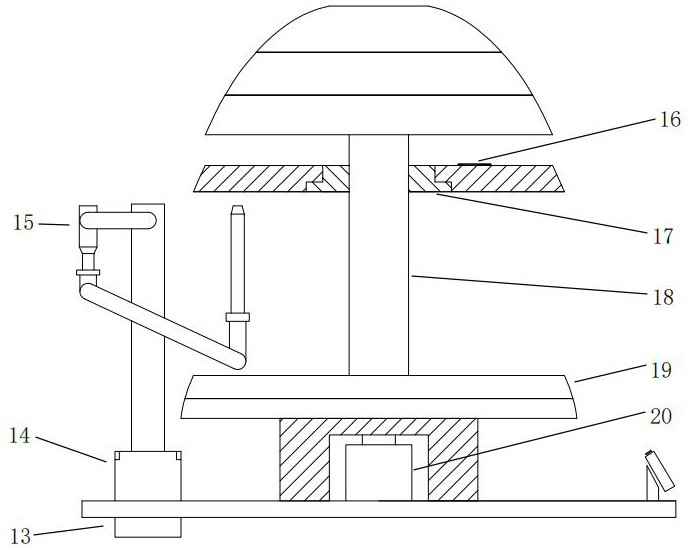

[0019] The technical solution of the present invention will be further explained below in conjunction with the accompanying drawings.

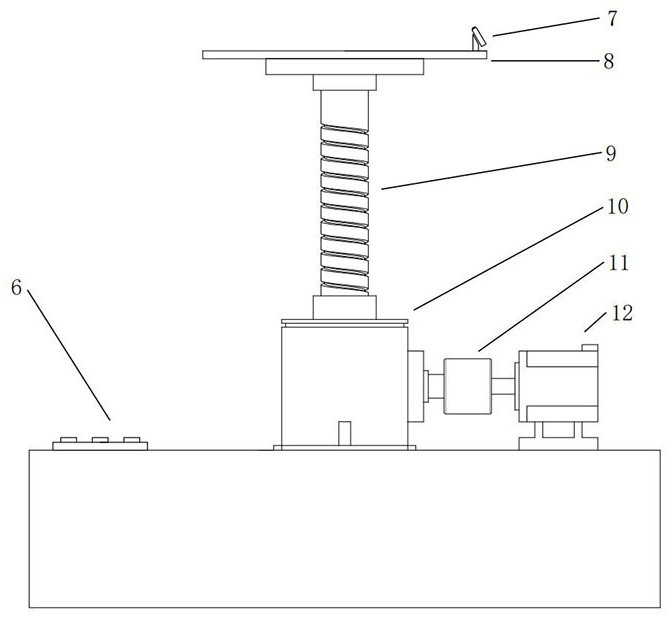

[0020] Such as figure 1 It is a structural schematic diagram of the discretization mandrel system of the three-dimensional braiding machine based on the variable-curvature special-shaped rotary body of the present invention. The assembly unit 2 is connected to the mandrel lifting unit 5, and the PLC6 is respectively connected to the mandrel assembly unit 2 and the mandrel lifting unit 5; as image 3 It is a schematic diagram of the structure of the core mold assembly unit. The core mold assembly unit 2 includes: a discrete core mold layer unit 1, a core mold interlayer locking mechanism 3 and a core mold layer unit lifting mechanism 4. The discretized core mold layer unit 1 consists of The variable curvature mandrel layer is composed of slices. The discretized mandrel layer unit 1 in the present invention is a three-dimensional discretized mo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com