High-speed and high-precision electric spindle integrating three-dimensional vibration active control function

An active control, three-dimensional vibration technology, applied in the direction of manufacturing tools, large fixed members, metal processing equipment, etc., can solve the problems of incomplete vibration monitoring and control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

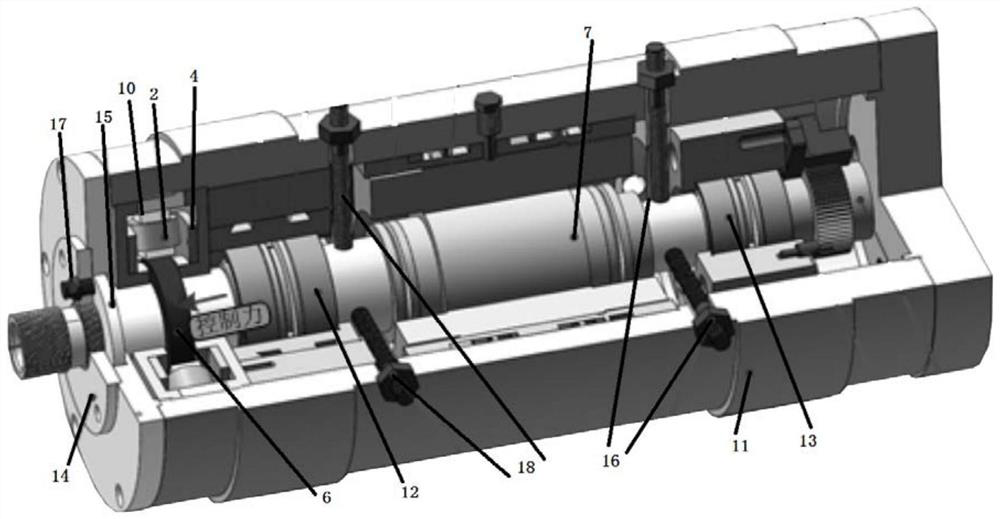

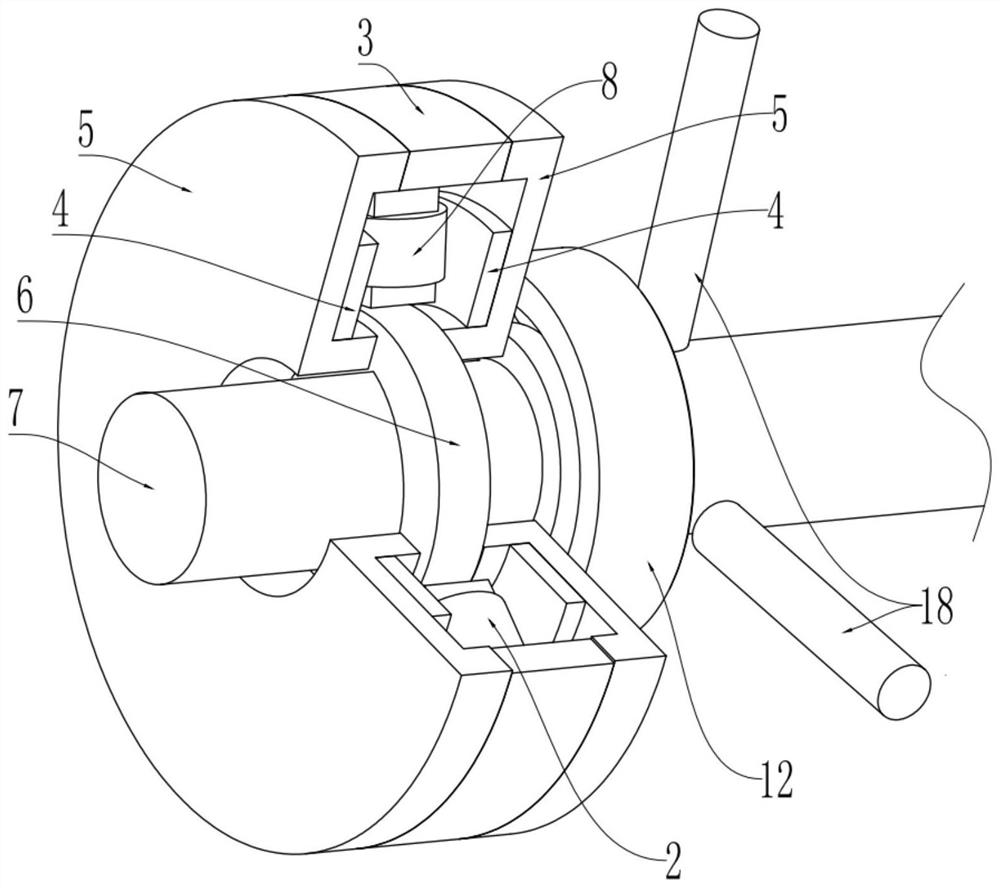

[0036] The embodiment is basically as attached Figure 1 to Figure 6 Shown:

[0037] combine figure 1, a high-speed and high-precision electric spindle integrated with three-dimensional vibration active control functions, including a main shaft body 7 and a housing 11, the main shaft body 7 is rotatably connected to the housing 11 through a front bearing 12 and a rear bearing 13, and the front bearing 12 and the rear Bearing 13 adopts two pairs of precision hybrid ceramic ball bearings, and also includes actuator 10, radial displacement sensor, axial displacement sensor and processor. Actuator 10 includes radial stator 3, radial control winding 2, shaft To the stator 5 and the axial control winding 4, the radial stator 3 is integrally formed with a radial control magnetic pole 1, the radial control winding 2 is wound on the radial control magnetic pole 1, the radial control winding 2, the axial control winding 4, Both the radial displacement sensor and the axial displacement...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com