Vibration and noise reduction structure for generator components, generator components, generator

A technology for vibration reduction and noise reduction and generator sets, which is applied in the fields of generators, motor vibration and noise reduction structures, and generator set vibration and noise reduction control. Improve ventilation performance, reduce processing cost and manufacturing complexity, and improve the effect of high-frequency vibration resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

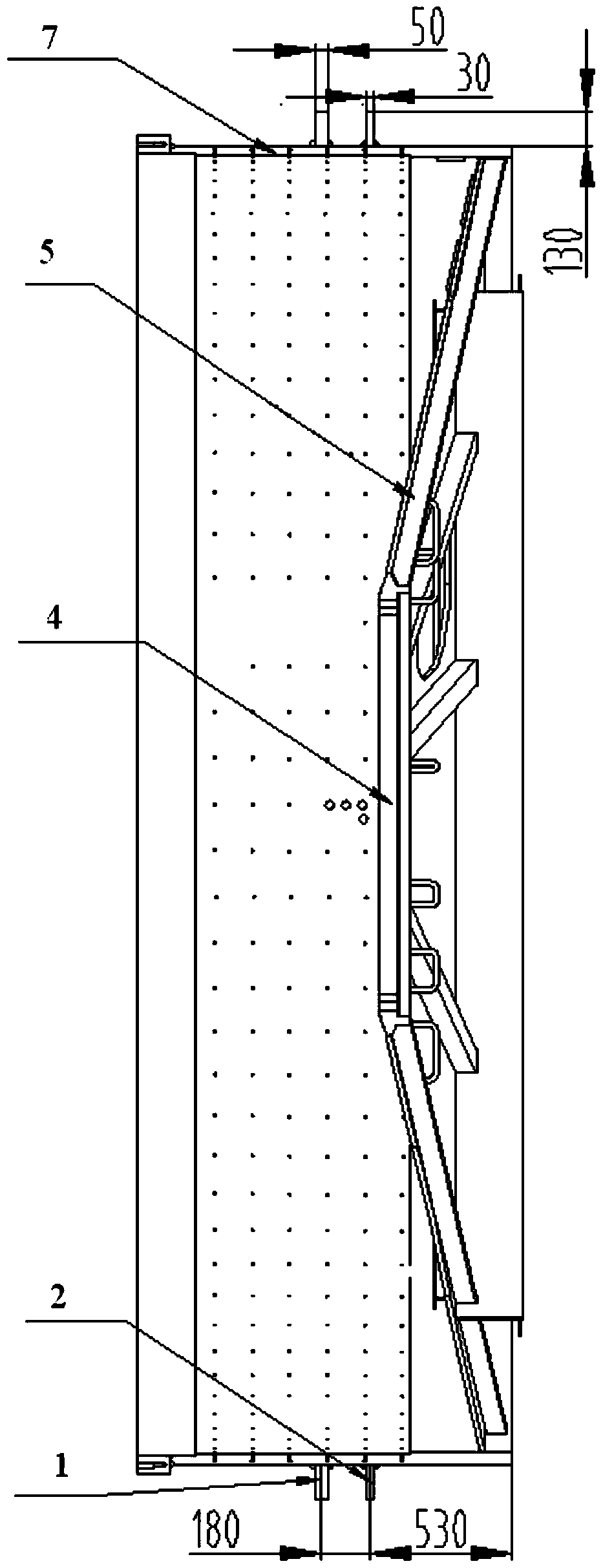

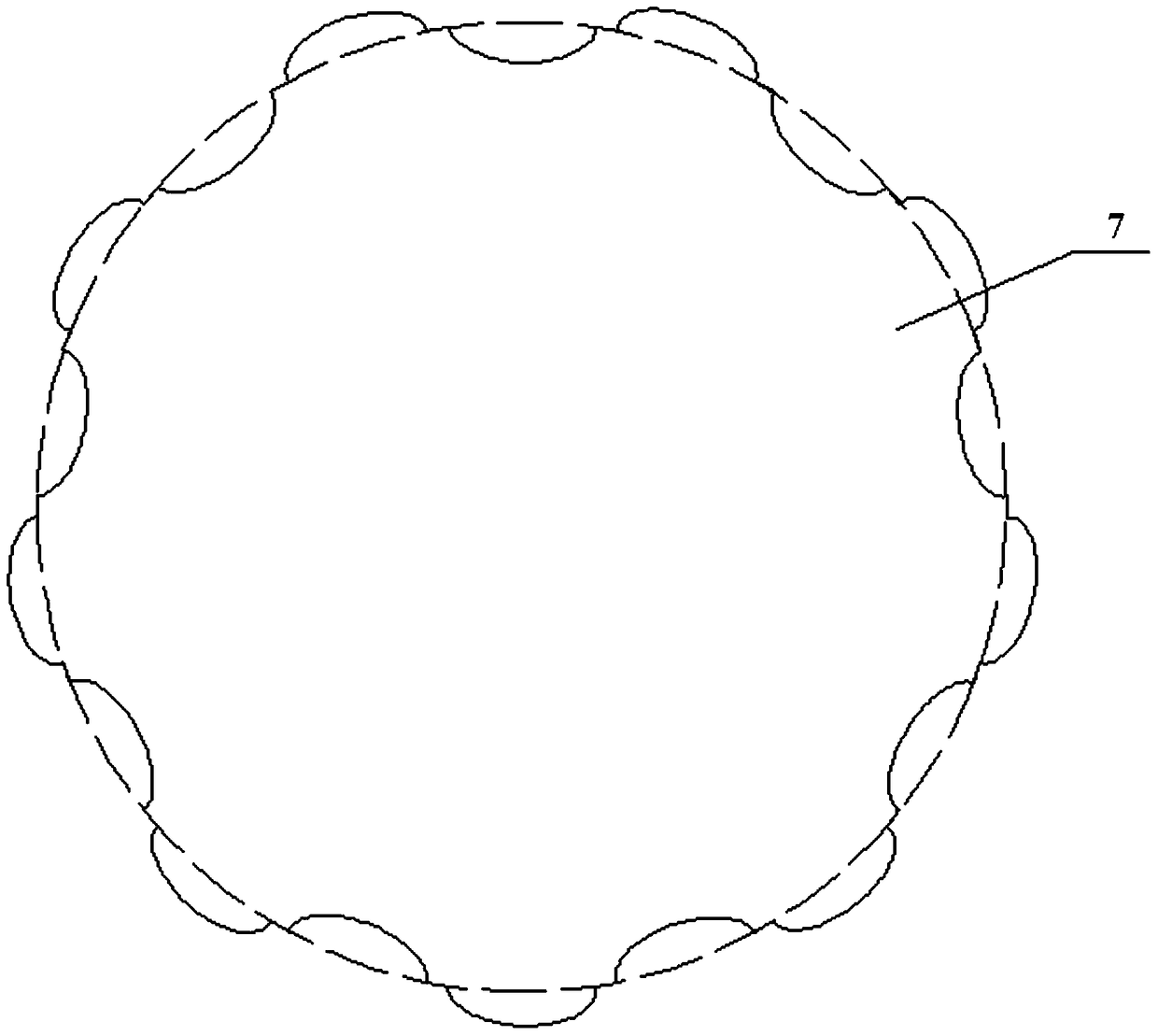

[0034] Preferred embodiments of the present invention will be specifically described below in conjunction with the accompanying drawings, wherein the accompanying drawings constitute a part of the application and are used to explain the present invention together with the embodiments of the present invention.

[0035] For direct-drive wind turbines, the structural characteristics of the generator have similar frequency and phase characteristics to the electromagnetic force of the generator. From the perspective of structural design and simulation analysis, the present invention designs a new type of structure fixed on the outer wall of the thin-walled structure of the generator rotor so that the structural characteristics of the generator rotor avoid its electromagnetic force similar to the mid-high frequency band and phase characteristics, thereby reducing power generation. The structure noise of the machine in the middle and high frequency bands.

[0036] According to the st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com