Electrical load management and control method, system, equipment and medium

A technology of power load and management and control system, applied in the direction of power network operating system integration, information technology support system, electrical components, etc., can solve the problem of increasing power grid and circuit power supply pressure, unable to timely control the power load of equipment, and low efficiency of manual calculation And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

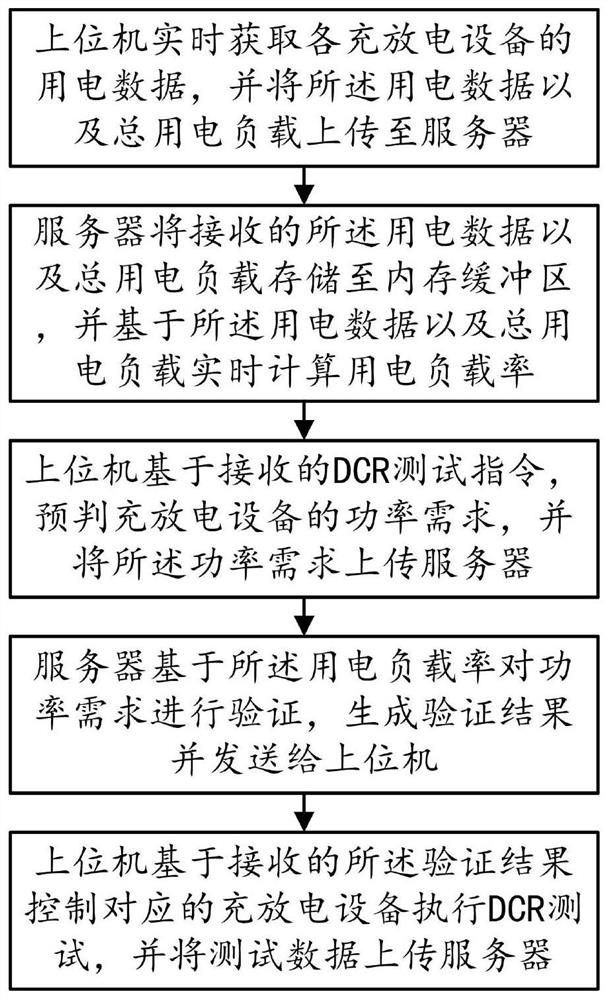

[0045] This embodiment provides a power load control method, such as figure 1 and Figure 5 shown, including the following steps:

[0046] Step S10, the upper computer obtains the power consumption data of each charging and discharging equipment in the factory area in real time, and uploads the power consumption data and the total power consumption load to the server; the total power consumption load is the maximum load that the factory area can bear; through Obtain the power consumption data in real time to ensure the stability of power consumption of all charging and discharging equipment in the factory area;

[0047] Step S20, the server stores the received power consumption data and the total power consumption load in the memory buffer, and calculates the power consumption load rate in real time based on the power consumption data and the total power consumption load; by storing the power consumption data and the total power consumption load The total power load is store...

Embodiment 2

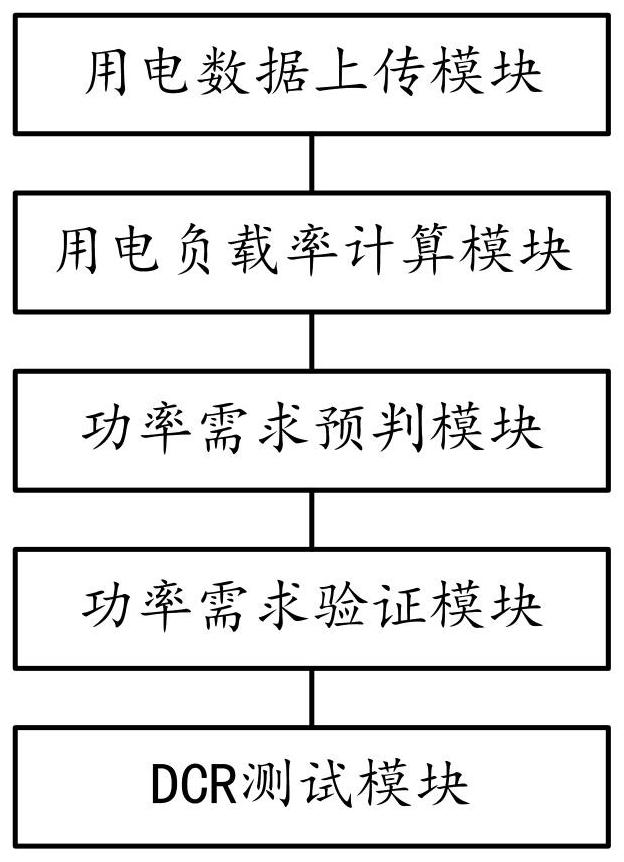

[0058] This embodiment provides an electric load control system, such as figure 2 and Figure 5 As shown, the following modules are included:

[0059] The power consumption data upload module is used for the upper computer to obtain the power consumption data of each charging and discharging equipment in the factory area in real time, and upload the power consumption data and the total power consumption load to the server; the total power consumption load is what the factory area can bear The maximum load; by obtaining the power consumption data in real time, it is convenient to ensure the power consumption stability of all charging and discharging equipment in the factory area;

[0060] The power consumption load rate calculation module is used for the server to store the received power consumption data and the total power consumption load in the memory buffer, and calculate the power consumption load rate in real time based on the power consumption data and the total power...

Embodiment 3

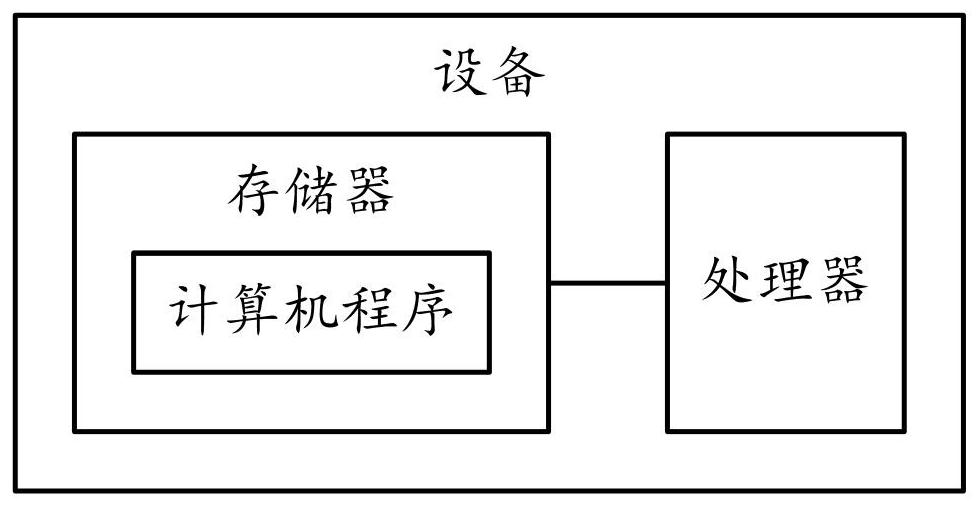

[0072] This embodiment provides a power load control device, such as image 3 As shown, it includes a memory, a processor, and a computer program stored in the memory and operable on the processor. When the processor executes the computer program, any implementation manner in Embodiment 1 can be realized.

[0073] Since the electronic device introduced in this embodiment is the device used to implement the method in Embodiment 1 of this application, based on the method described in Embodiment 1 of this application, those skilled in the art can understand the electronic device of this embodiment. Specific implementation methods and various variations thereof, so how the electronic device implements the method in the embodiment of the present application will not be described in detail here. As long as a person skilled in the art implements the equipment used by the method in the embodiment of the present application, it all belongs to the protection scope of the present applica...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com