Digital sensor junction box and weighing system based on junction box

A digital sensor and weighing system technology, applied in the field of electronic scales, can solve the problems of laboriousness, inability to query the internal code value of the sensor weighing, labor consumption, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

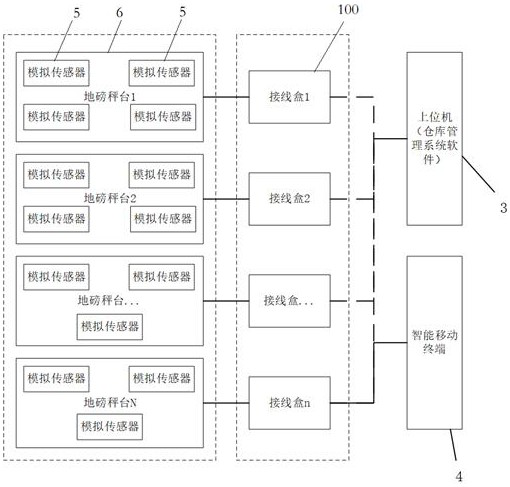

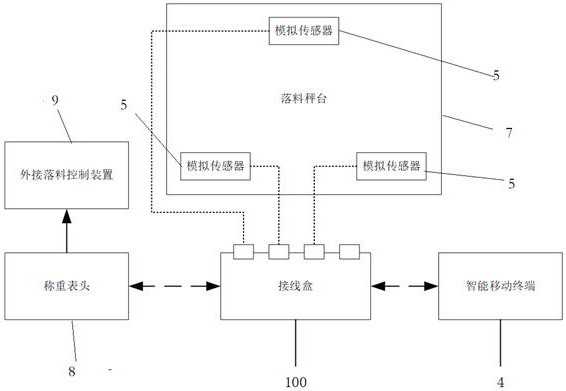

[0041] See figure 1 A digital sensor junction box 100, includes a main board 1 and at least one analog to digital converter board 2, the motherboard 1 is welded a first master unit to each other communication connection 11 and the first communication module 12, each of the mold 2 welded to digital converter plate of the second master unit to each other communication connection 21 and the second communication module 22, the first communication module 12 respectively 3, communication of the mobile terminal 4 and the second communication module 22 is connected with the host computer the second master unit 21 also an external sensor 5 ( figure 1 The analog sensors) one correspondence communication connection, the second main control unit 21 stores a unique address code, the first main control unit 11 specified by the address code to access the second main control unit 21. The second master unit 21 can process signals from the sensor 5 outputs, for example, converts the analog signal i...

Embodiment 2

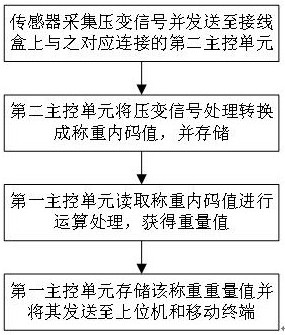

[0048] See figure 1 with image 3 A weighing system digital sensor junction box based, including use of the program junction box to one of the 100, is provided with a plurality of sensors, said stations 5, the PC 3 and the running load parameter adjustment APP mobile terminal 4, the said table a plurality of sensors 5 are connected to the junction box 100 one to one, the terminal box 100 is connected to the PC communication 3 and the mobile terminal 4 through the first communication module 12; the weighing system performing the weighing step is specifically: the sensor 5 acquired pressure change signal and sends it to the junction box 100 corresponding connected second master unit 21, the second main control unit 21 the pressure change signal processing is converted into Weighing the code value and storing; the first main control unit 11 transmits the reading to the second main control unit 21 commands, read weighing the code value, said first main control unit 11 of the weighing t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com