Rice dehumidification equipment

A technology for rice and equipment, which is applied in lighting and heating equipment, preservation of seeds through drying, filtering and sieving, etc. It can solve the problems of damp and moldy rice, rice agglomeration, uneven heating of rice, etc., and achieve the effect of preventing dehumidification from failing to meet the standard

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

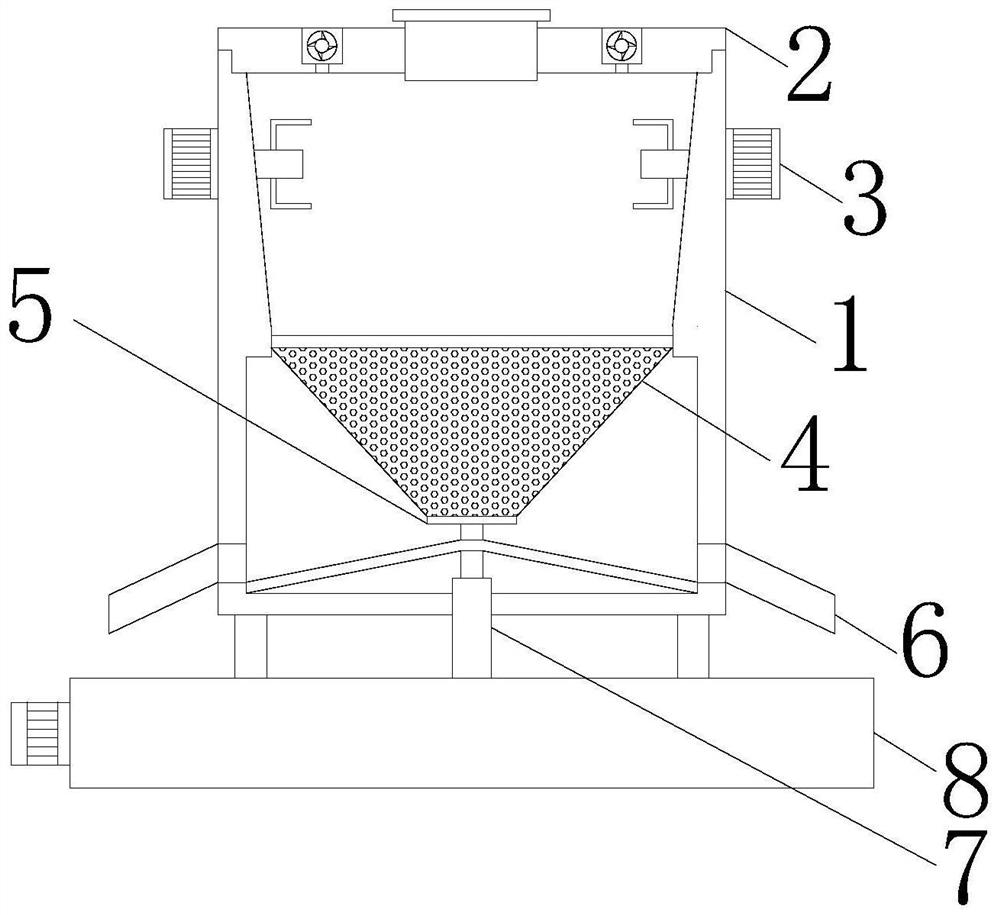

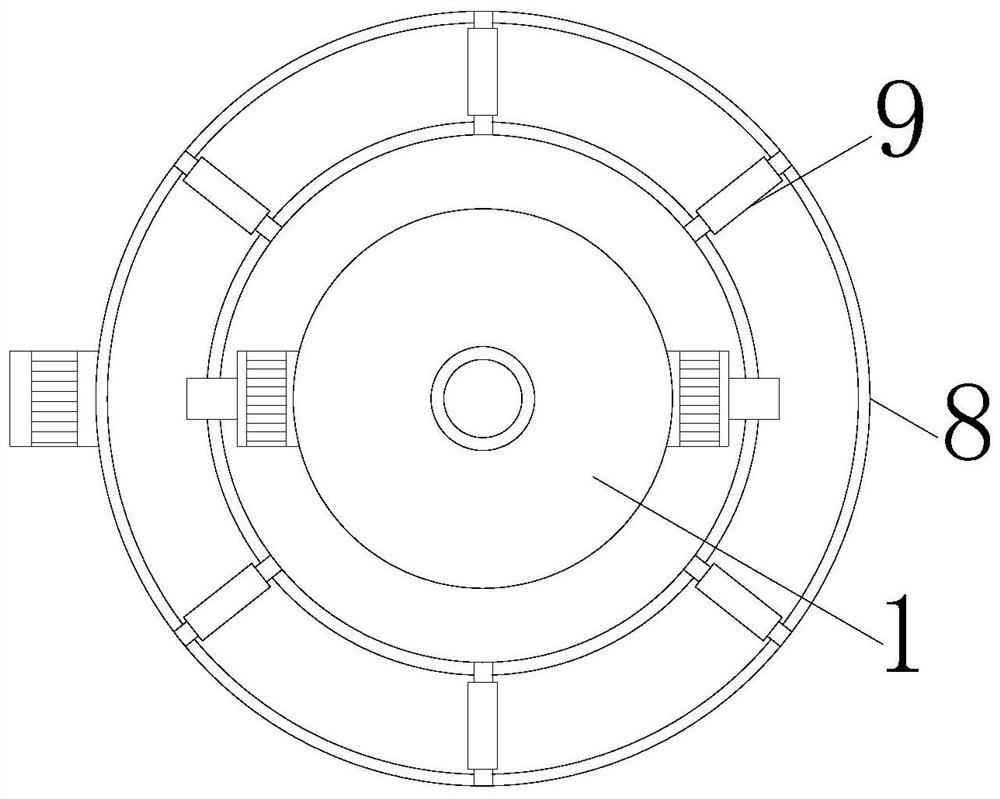

[0022] Refer Figure 1-4 The present invention proposes a millet dehumidification apparatus, including processing cylinder 1 and a drying mechanism; the processing cylinder is provided with a tubular conduction region, a tether region, and a tether region including a cover plate 2, and a feed passage on the cover 2. And the feed channel is threaded and connected to the cap, the inner wall of the cover plate 2 has a plurality of hot air, the cover 2 detachable mounting on the processing cylinder 1, and the processing cylinder 1 is provided with a moving plate 5 and for driving. The moving plate 5 is moved back and forth in the conductive region, the returning region, and the drive mechanism includes the electric push rod 7, and the drive rod of the electric push rod 7 is detachabled there is a moving plate 5; the moving plate 5 is connected to it. The screen 4 and the screen 4 edge are connected to the inner wall of the processing cylinder. The screen 4 is connected to the sleeve of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com