Well group development method

A well group and fracturing well technology, which is applied in the field of well group development, can solve the problems of low viscosity, poor sand carrying effect, not involving multi-well or well group fracturing mode, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The invention will be further described below with reference to the accompanying drawings.

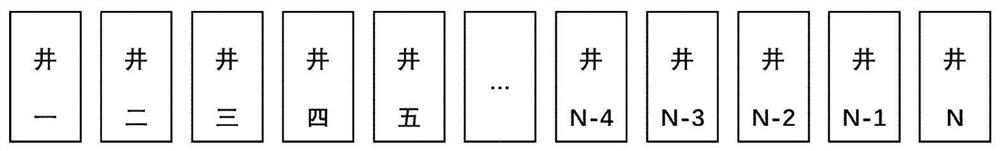

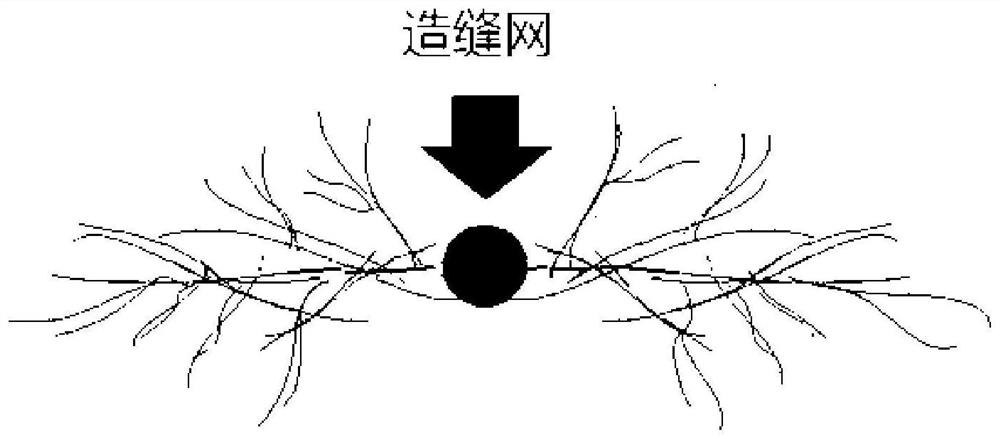

[0030] The application provides a development method of a well group for ultimately achieving the overall effectively transformation of the reservoir block based on the wellbential fracturing and improves capacity. In the well group development method, the well is operated in accordance with the coding order, and corresponding to the wells, the fracturing operation is carried out after the drilling operation, where at least one well is in the case, and the well is not in time to return production. Reduce the effect of rear pressure fracture in maintaining pressure. In the well on the well, at least one well is not fractured after the drilling, and thereby reducing the effect of fracturing on the drilling between the positive pressure fracture well and the positive drilling.

[0031] Below figure 1 One embodiment of the well group development method will be discussed in detail.

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com