Downhole power generation device for water injection well

A technology for power generation devices and water injection wells, which is applied in wellbore/well valve devices, electromechanical devices, hydroelectric power generation, etc. It can solve the problems of large power generation devices, increased costs, and small fluid kinetic energy, and achieve enhanced mechanical strength and stability. performance, improve power generation efficiency, and simplify the transmission structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

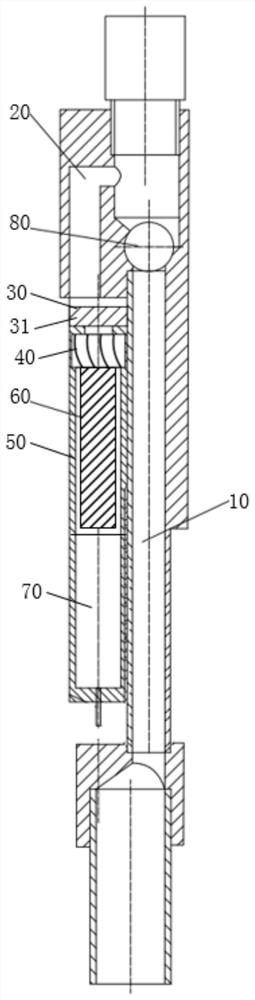

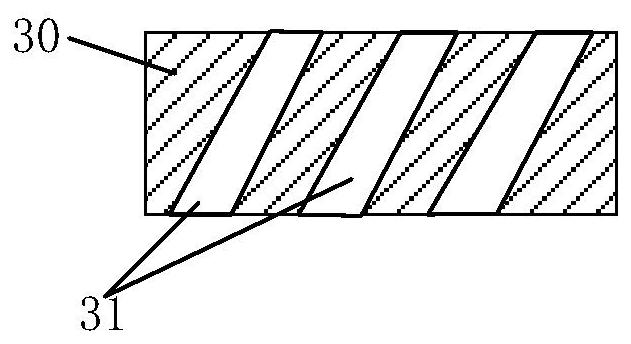

[0042] See figure 1 , an underground power generation device for a water injection well, comprising: a generator body arranged on the water outlet of the branch channel 20 on the side of the main water injection channel 10 in the well. One side of the water injection main channel 10 is provided with a branch channel 20 , the water inlet of the branch channel 20 communicates with the water injection main channel 10 , and the water outlet of the branch channel 20 is provided with a generator body. The main water injection channel 10 is provided with a plug 80 below the water inlet of the branch channel 20. When power generation is required, the plug 80 can block the main water injection channel 10, and the water flow entering the main water injection channel 10 can enter from the branch channel 20. Thus acting on the generator body, the generator body is started to generate electricity.

[0043] The generator body of this embodiment is arranged on the side of the main water inj...

Embodiment 2

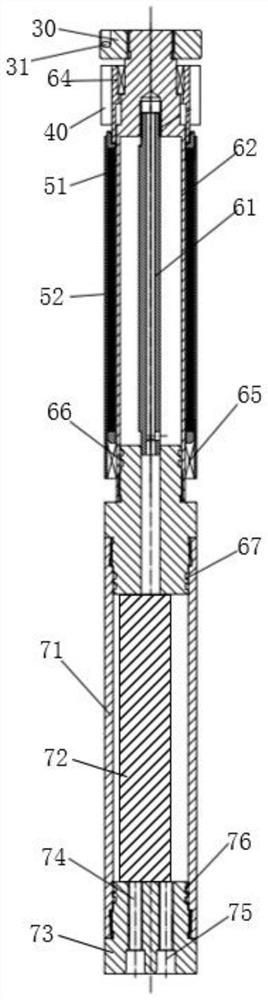

[0052] Such as image 3 As shown, on the basis of the first embodiment, this embodiment further defines that the outer rotor assembly 50 includes: a permanent magnet 51 and a rotor casing 52 . The inner stator assembly 60 includes: a stator core 61 and a stator shell 62 . The stator casing 62 is installed in the rotor casing 52, one end of the stator casing 62 is fixedly connected with the deflector plate 30 and rotatably connected with the turbine 40, and the other end of the stator casing 62 is fixedly connected with the power generation circuit assembly 70 and connected with the other end of the rotor casing 52. One end swivels to connect. The stator core 61 is fixed inside the stator shell 62 . The stator core 61 is screwed to the stator housing 62 . The permanent magnet 51 is fixed on the inner wall of the rotor housing 52 , and the permanent magnet 51 is located between the rotor housing 52 and the stator housing 62 . One end of the rotor housing 52 is fixedly connec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com