Fabricated bridge safety channel and construction method

A safety channel and prefabricated technology, which is applied in the direction of construction, building structure, and building material processing, can solve the problems of high cost, poor channel stability, troublesome and time-consuming installation and dismantling of safety channels, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

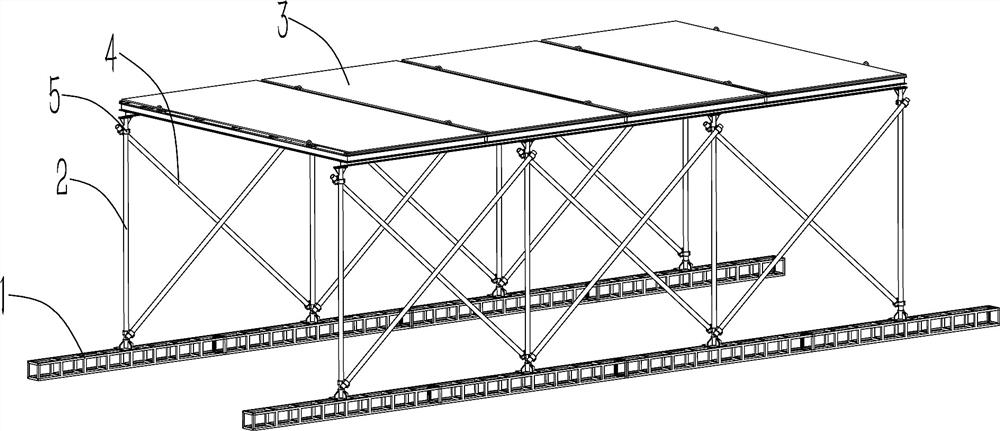

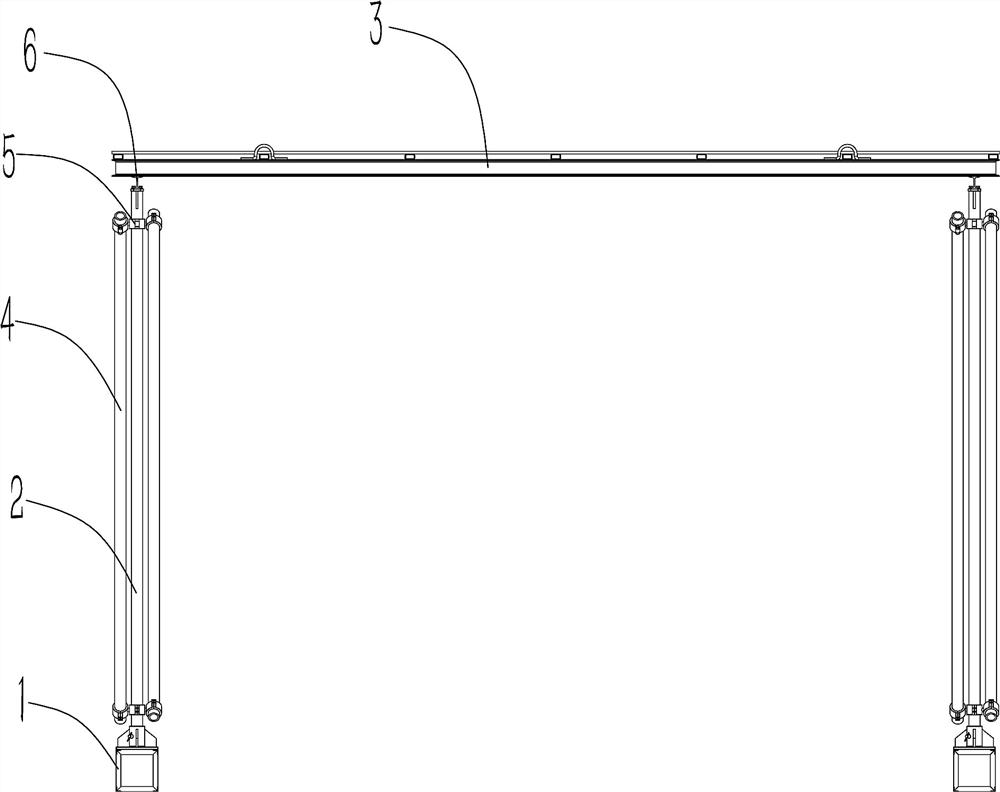

[0043] Such as Figure 1~11 As shown, a prefabricated bridge safety channel and its construction method include a plurality of bases 1 installed along the road shoulders on both sides of the road. Columns 2 are fixed on the bases 1, and columns 2 are fixed between two adjacent columns 2. Longitudinal beam 6 and scissors strut 4, multiple upper cover plates 3 are fixed on the longitudinal girder 6, the upper cover plate 3 covers both sides of the road on the projection plane, and connecting mechanism 5 is provided between the scissors strut 4 and the column 2 , The scissors strut 4 connects and supports two adjacent columns 2 through a connecting mechanism 5 . Due to this structure, in order to avoid damage to people and objects caused by falling objects falling into the normal road during bridge construction, it is necessary to set up a safety passage on the road under the bridge to ensure the normal passage of people and vehicles. , to avoid long-term construction blocking t...

Embodiment 2

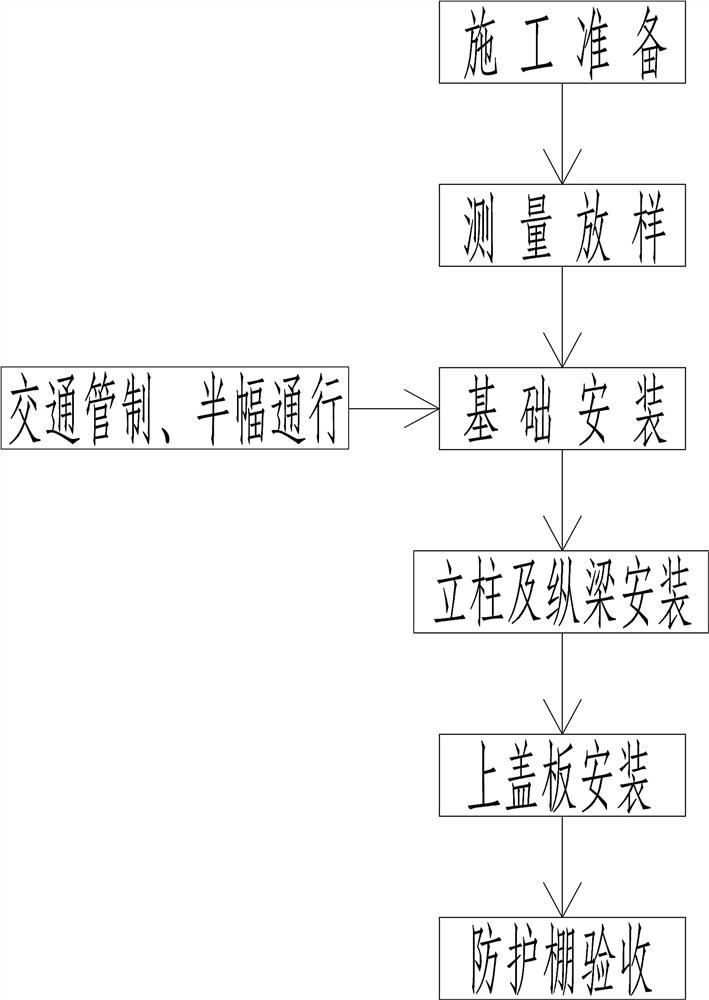

[0056] Such as Figure 1~9 , further illustrate in conjunction with embodiment 1, carry out measurement stakeout to road both sides road shoulder by total station, determine safety passage span, height size; Carry out traffic control, half-width traffic, carry out the base seat 1 installation of safety passage at road both sides road shoulder, The base 1 is filled with discarded concrete test block 106 as a gravity structure, and welded steel bars 105 are added to prevent the concrete test block 106 from moving; the column 2 is installed, and the bottom of the column 2 is inserted into the column mounting seat 103 on the base 1 and passed through the pin The shaft 104 is fixed with the cotter pin, fixed after adjusting the verticality of the column 2, and then the longitudinal beam 6 and the scissors brace 4 are installed, the two ends of the longitudinal beam 6 are fixed on the connecting plate 201 on the column 2 by bolts, The strut 4 is fixedly connected with the column 2 t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com