Swing type energy dissipation and shock absorption mechanism suitable for fabricated building

A shock-absorbing mechanism and swing-type technology, applied in building components, protective buildings/shelters, buildings, etc., can solve problems such as jamming, and achieve high reliability, large output, and stable energy consumption performance for a long time. changing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

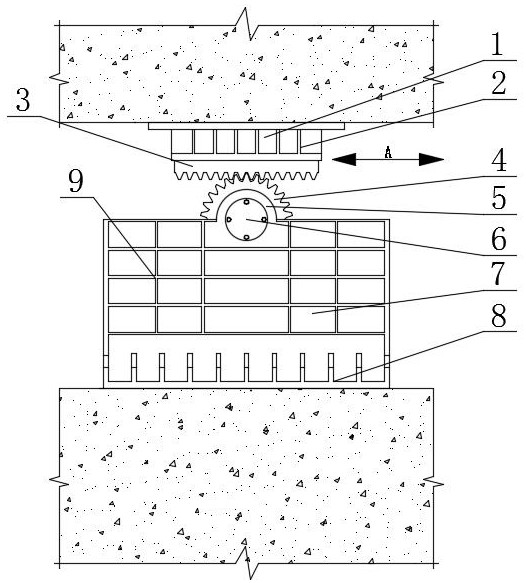

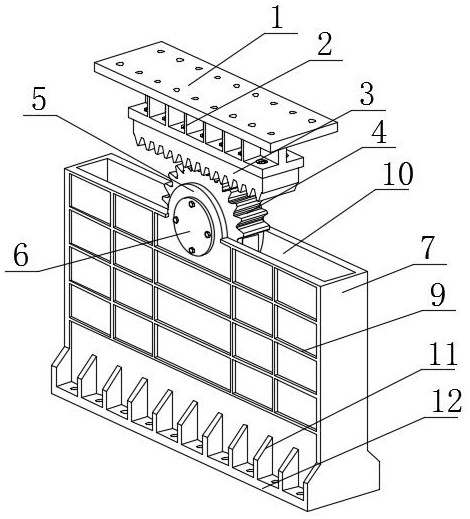

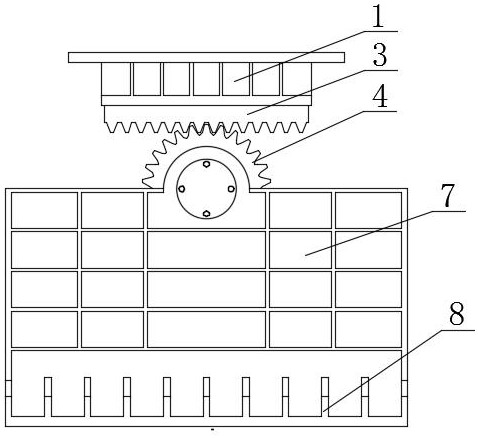

[0033] Such as Figure 1-9 Shown: a swinging energy-dissipating shock-absorbing mechanism suitable for prefabricated buildings, including a superstructure, a substructure, and a buffer mechanism connecting the superstructure and the substructure. The buffer mechanism includes a damping box 7 connected to the substructure. A cavity 10 is arranged in the damping box 7, the opening of the cavity 10 is located at the upper end of the damping box 7, a damping liquid is arranged in the cavity 10, a rotating mechanism is arranged at the upper end of the damping box 7, and a rotating mechanism is arranged on the rotating mechanism. A swinging member 13 is provided, the lower part of the swinging member 13 extends into the cavity 10, the upper end of the swinging member 13 is a semicircular first transmission member, and the lower part of the superstructure is provided with a second transmission member matched with the first transmission member. Two transmission parts.

[0034] The fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com