Photochromic super-hydrophobic functional paper as well as preparation method and application thereof

A photochromic and super-hydrophobic technology, applied in the field of papermaking, can solve problems such as limiting the large-scale application of paper products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

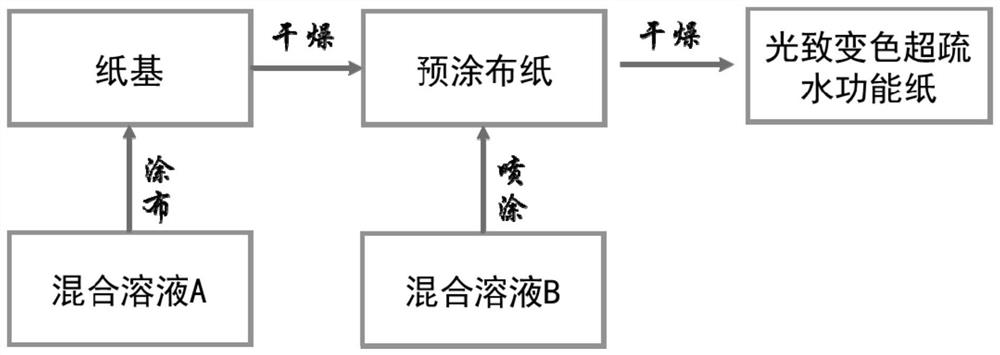

Method used

Image

Examples

Embodiment 1

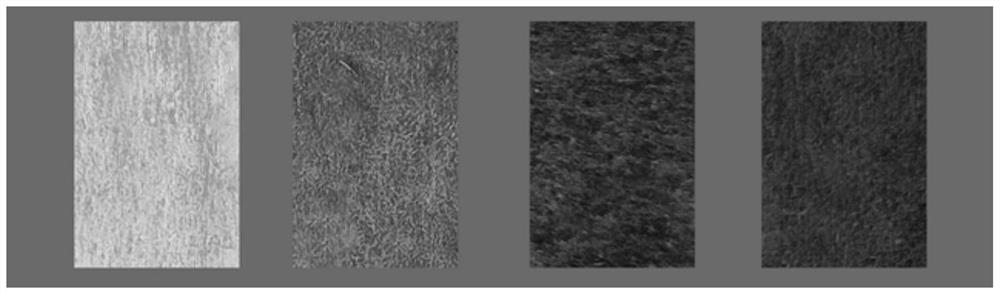

[0031] (1) Fully stir 10g of ammonium metatungstate, 4g of polyvinylpyrrolidone, 2.2g of ethylene glycol and 22g of water to obtain mixed solution A.

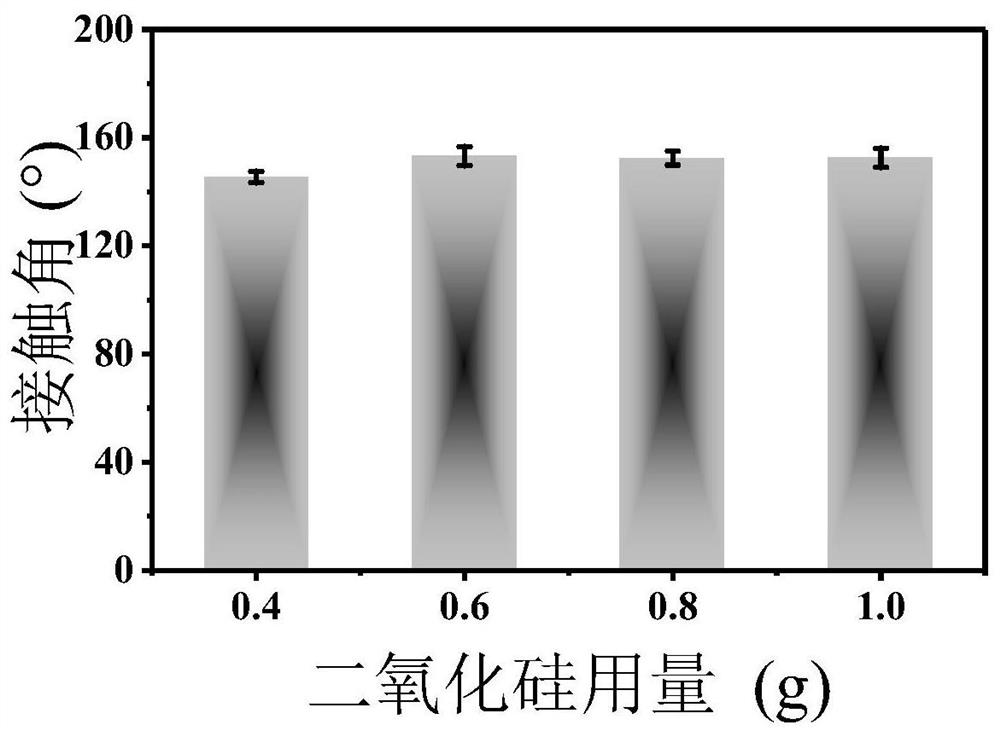

[0032] (2) 0.8g of silicon dioxide, 20g of n-hexane, and 1.2g of polydimethylsiloxane were mixed and stirred to obtain a mixed solution B.

[0033] (3) The obtained mixed solution A is evenly coated on the surface of the paper with a coating thickness of 100 μm, and dried at room temperature (24-26° C., 40-50%) to obtain a pre-coated paper.

[0034] (4) Spray the obtained mixed solution B evenly with a spray gun (spraying distance: 20cm) onto the surface of the pre-coated paper, and place it in an oven (60°C) for 3 hours.

[0035] (5) The dried sample was taken out, and the above-mentioned spraying and drying treatments were repeated to obtain a photochromic superhydrophobic functional paper.

Embodiment 2

[0037] (1) Fully stir 20g of ammonium metatungstate, 4g of polyvinylpyrrolidone, 2.2g of ethylene glycol and 22g of water to obtain mixed solution A.

[0038] (2) 0.7g of silicon dioxide, 22g of n-hexane, and 1.2g of polydimethylsiloxane were mixed and stirred to obtain a mixed solution B.

[0039] (3) The obtained mixed solution A is evenly coated on the surface of the paper with a coating thickness of 100 μm, and dried at room temperature (24-26° C., 40-50%) to obtain a pre-coated paper.

[0040] (4) Spray the obtained mixed solution B evenly with a spray gun (spraying distance: 25cm) onto the surface of the pre-coated paper, and place it in an oven (40°C) for 6 hours.

[0041] (5) The dried sample was taken out, and the last spraying and drying process was repeated to obtain a photochromic superhydrophobic functional paper.

Embodiment 3

[0043] (1) Fully stir 40g ammonium metatungstate, 3g polyvinylpyrrolidone, 2g ethylene glycol and 22g water to obtain mixed solution A.

[0044] (2) 0.4 g of silicon dioxide, 15 g of n-hexane, and 0.5 g of polydimethylsiloxane were mixed and stirred to obtain a mixed solution B.

[0045] (3) The obtained mixed solution A is evenly coated on the surface of the paper with a coating thickness of 150 μm, and dried at room temperature (24-26° C., 40-50%) to obtain a pre-coated paper.

[0046] (4) Spray the obtained mixed solution B evenly with a spray gun (spraying distance: 30cm) onto the surface of the pre-coated paper, and place it in an oven (80°C) for 2 hours.

[0047] (5) The dried sample was taken out, and the last spraying and drying process was repeated to obtain a photochromic superhydrophobic functional paper.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Coating thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com