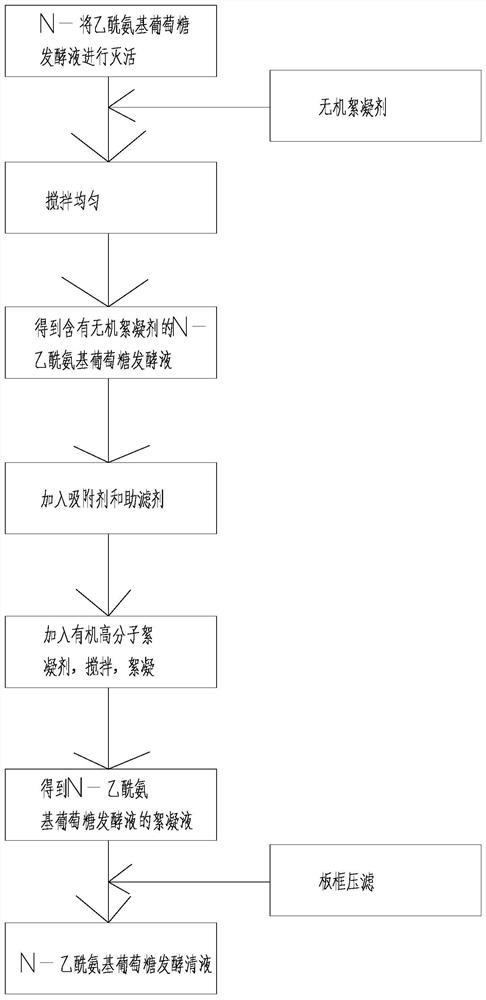

Method for preparing N-acetylglucosamine fermentation clear liquid by using composite flocculant

A technology of glucose fermentation liquid and composite flocculant, which is applied in the field of bioengineering, can solve the problems of small bacteria, large amount of bacteria, and inability to filter the bacteria plate and frame, and achieve the effect of promoting flocculation, reducing dosage, and improving flocculation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0038] Take high engineered bacteria density N- acetylglucosamine broth 40L, concentrated fermentation bacteria OD = 97, 85 ℃ jacket was heated to inactivate; open stirring to 450rpm, was added 200g (W / V) PFS, pH adjusted to 4.5, was added with stirring 160g 240g celite and activated carbon, after stirring for 10min, the stirring speed reduced to 110 rpm, at which time the solution was added 100ml 2% chitosan concentration, reduced stirring speed of 50 rpm uniformly stirred, while cooling after stopping stirring to 50 deg.] C, stationary for 30 min flocculation; then frame filter; whole broth had to be finished, for the top 30% of pure water, and dry plate and frame, the finally obtained clear N- acetylglucosamine fermentation liquid 45L, acetylglucosamine yield 99%, 7kg bacterial sludge cake, the moisture content of 68%.

example 2

[0040] Take high engineered bacteria density N- acetylglucosamine broth 340L, concentrated fermentation bacteria OD = 110, the jacket was heated to 95 deg.] C inactivated; open 300rpm stirring to inactivation, addition of 2.0kg PFS adjusted to pH 5.0 while stirring was added 4.0kg and 6.0kg activated carbon through celite. after stirring 10min, the stirring speed reduced to 110 rpm, at which time the solution concentration of 3% chitin 600ml, stirred for 10min after cooling to 50 ℃, the speed at 50rpm continued slow stirring, flocculation 60min, then plate and frame filter, filtration time 3h, the fermentation broth until all filters finished, the top 20% of the filter cake was washed with pure water, and dry plate and frame, the finally obtained fermentation liquid acetylglucosamine 370L, N- acetylglucosamine yield 98%; bacterial sludge filter cake was 79kg, 74% moisture content.

example 3

[0042] Take high engineered bacteria density N- acetylglucosamine broth a 4T, concentrated fermentation bacteria OD = 82, the jacket was heated to 95 deg.] C inactivated; inactivated broth after the flocculation tank 10t of hit, stirred open to the 50Hz, 20kg PFS was added to adjust pH to 4.5, while stirring, added 16kg 24kg celite and activated carbon, after stirring for 10min and the stirring speed reduced to 30Hz, chitin case 10L solution concentration of 2% was added, stirred for 10min cooled to 50 ℃, stirring was stopped flocculation 60min, then plate and frame filter; broth until all filters finished, the top 10% of the filter cake was washed with pure water, and dry plate and frame, the finally obtained N- acetylglucosamine fermentation liquid 3.7t, N- acetylglucosamine yield 98%; bacterial sludge cake 650kg, 68% moisture content.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com