Ink-jet printing system for cylinders

A technology of inkjet printing and inkjet printing device, which is applied in the field of cylindrical inkjet printing systems, and can solve the problems of low printing efficiency and inability to mass-produce cylindrical products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

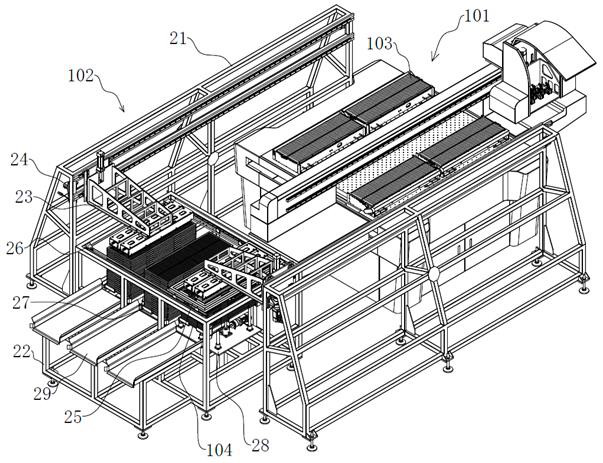

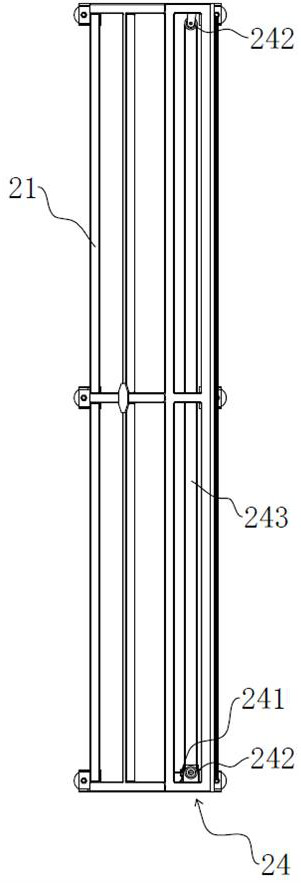

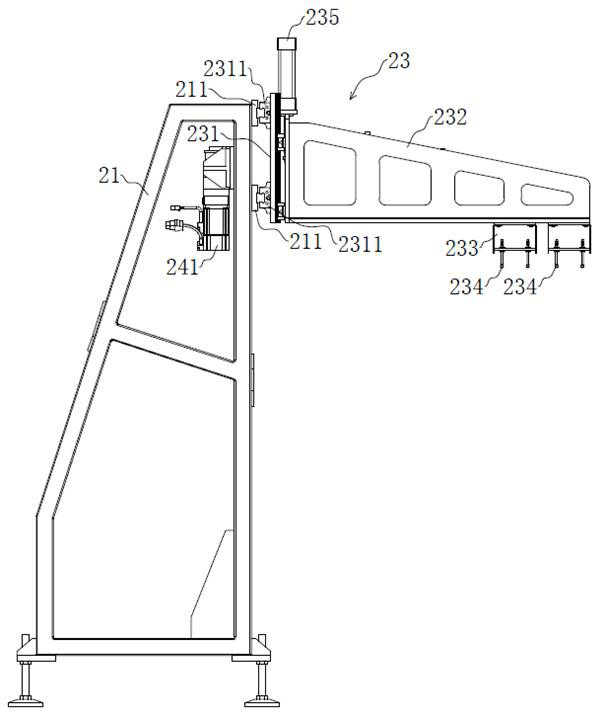

[0005] The following is attached Figure 1-12 The application is described in further detail. The embodiment of the present application discloses a cylindrical inkjet printing system, refer to figure 1 , including an inkjet printing device 101 and an automatic loading and unloading device 102 . refer to figure 1 with figure 2 , the automatic loading and unloading device 102 includes a frame 21, a tray 104, a grab assembly 23, a reciprocating drive structure 24, a push frame 25, a translation drive structure 26, a loading pallet 142 assembly, a blanking pallet 142 assembly and a spare Bracket 29. The frame 21 is arranged on the side of the tray 104 frame, and the grabbing assembly 23 is horizontally slid and assembled on the frame 21 along the Y axis. The grabbing assembly 23 is above the tray 104 frame and the printing device of the cylindrical inkjet printing system The reciprocating drive structure 24 is arranged between the grasping assembly 23 and the frame 21; the p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com