Lathe with high machining precision

A technology of processing precision and lathe, which is applied in the direction of metal processing equipment, turning equipment, turning equipment, etc., can solve the problems of reducing flange processing precision and stability, so as to reduce the probability of slippage, improve stability and improve efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

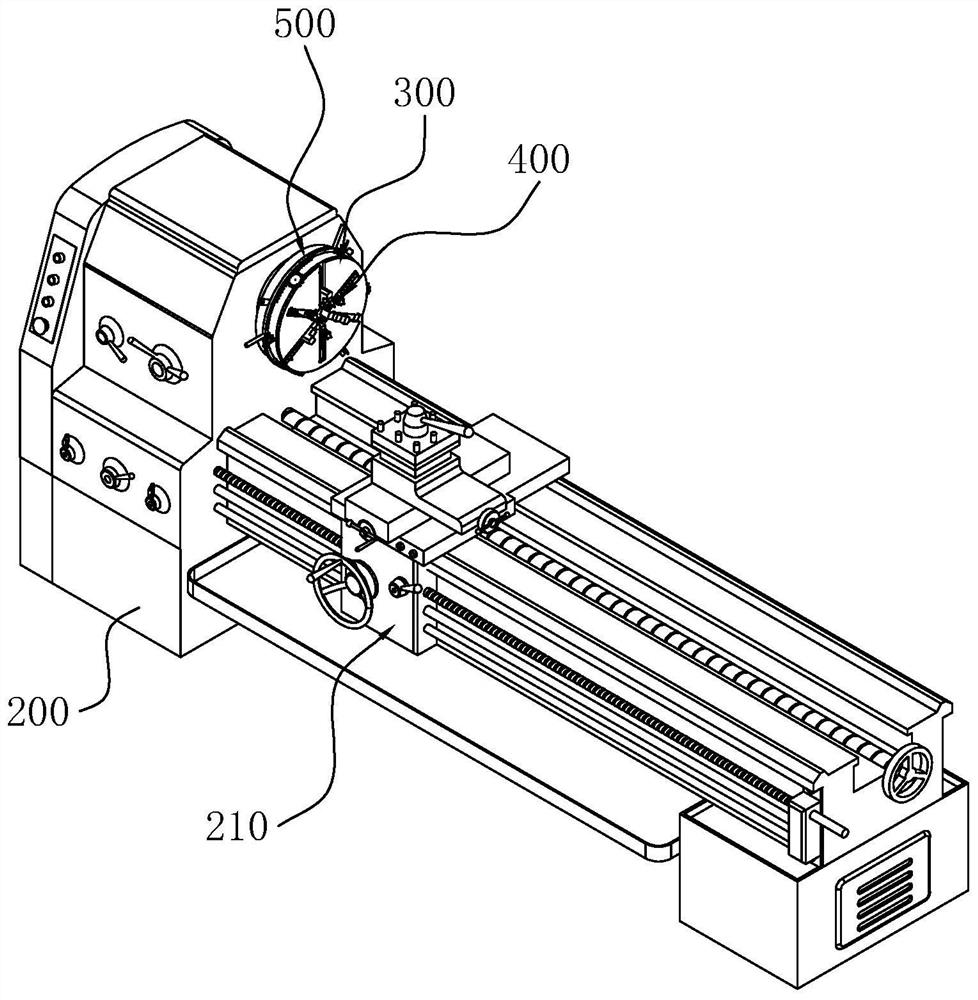

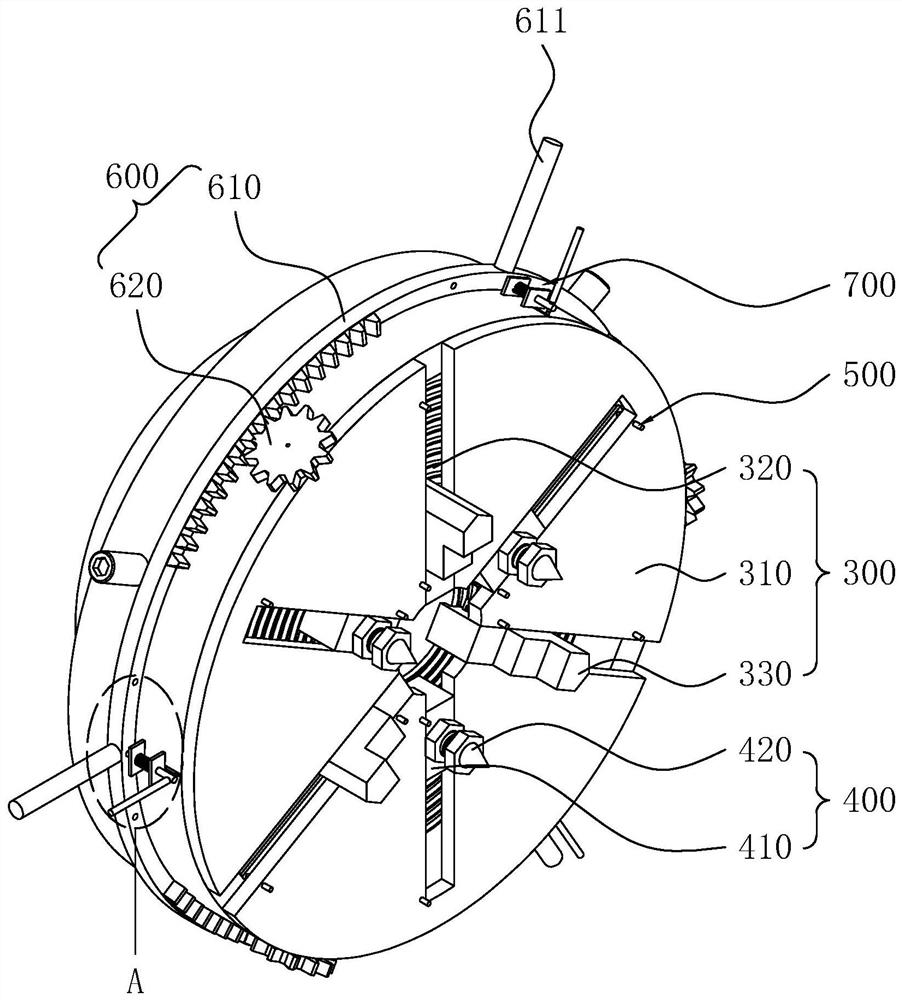

[0037] The following is attached Figure 1-5 The application is described in further detail.

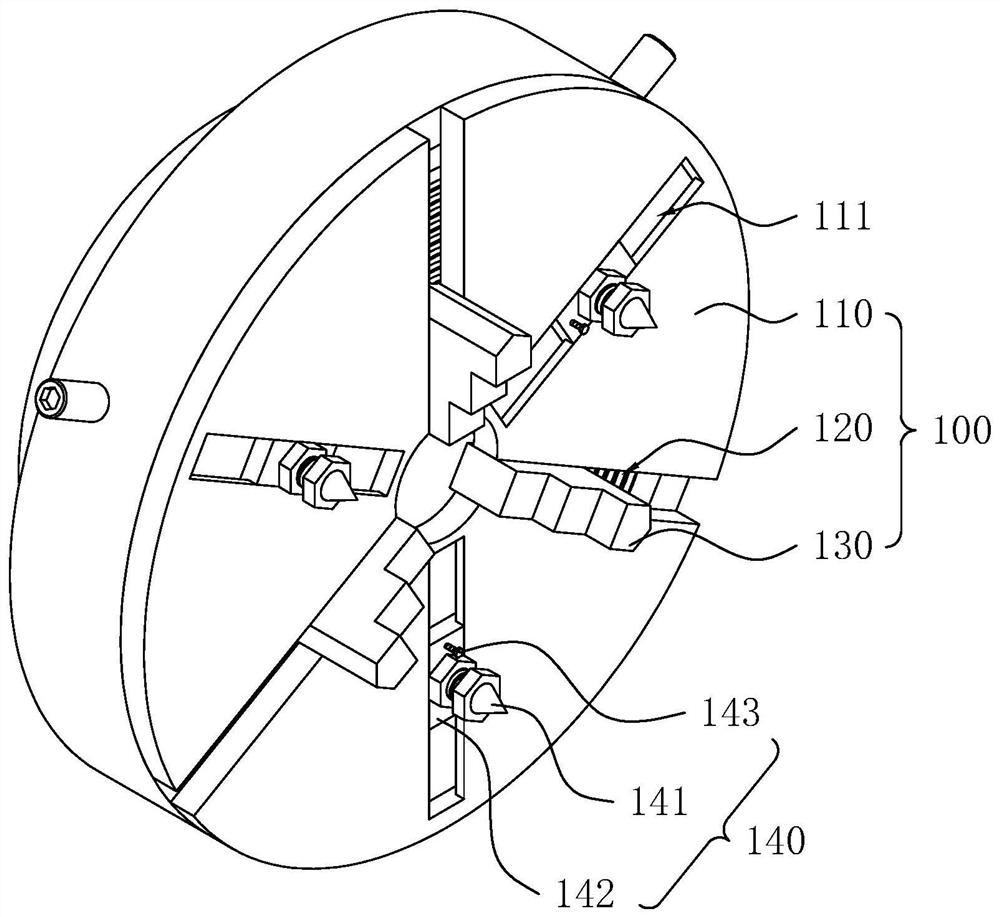

[0038] refer to figure 1 , in the related art, a three-jaw chuck 100 with a positioning assembly 140 includes a disk body 110 , a spiral disk 120 and three jaws 130 , and the positioning assembly 140 is disposed on the disk body 110 of the three-jaw chuck 100 . The positioning assembly 140 includes three sliders 142, three top cones 141 and three locking bolts 143. The disk body 110 is provided with three sliding slots 111 along its radial direction, and the three sliding grooves 111 are evenly distributed in the circumferential direction of the disk body 110. It is provided that one slide block 142 is correspondingly arranged in one slide groove 111 , and one top cone 141 is correspondingly threaded on one slide block 142 . The locking bolt 143 is threadedly connected to the slider 142, and the end of the locking bolt 143 far away from its own bolt head passes through the slider 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com