Production process of pre-molten material for continuous crystallizer protecting slag

A continuous casting crystallizer and production process technology, applied in the direction of improving process efficiency, etc., can solve the problems of large differences in physical properties of solid melts, uneven melt composition time periods, increased production costs, etc., to achieve stable physical and chemical properties of products , the effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

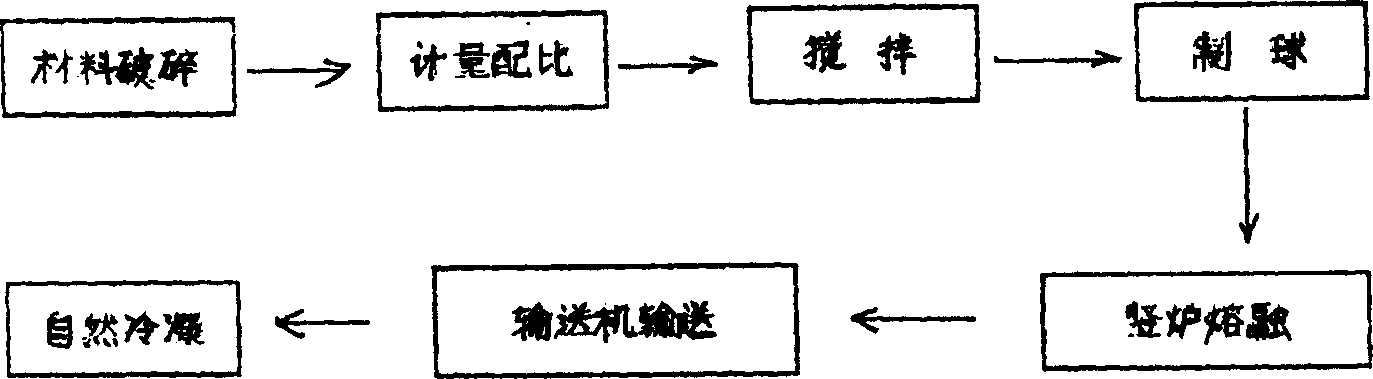

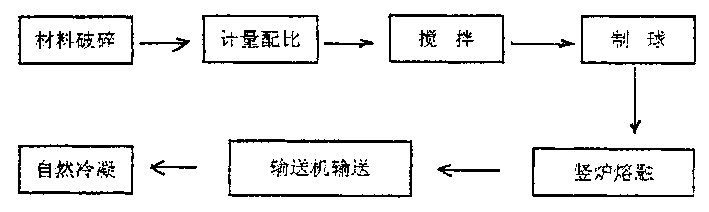

[0014] The process of the present invention is as follows: all kinds of raw materials are respectively coarsely crushed and finely crushed to a particle size of ≤5 mm; according to the requirements, with a certain weight and a binder loess ratio, they are fully stirred and evenly mixed by adding an appropriate amount of water into a drum mixer, and the homogenized material The briquette machine is continuously pressed into a hollow block with a certain geometric size and appropriate mechanical strength. The hollow block material and coke are added to the furnace for melting in proportion. The molten material is continuously discharged from the furnace and enters the condensing conveyor. Shaped solid solution, which is continuously transported and condensed naturally.

[0015] The application of the above-mentioned technology makes the chemical composition of the product uniform and the physical performance consistent, which improves and stabilizes the quality of the final produ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com