Movable support for spraying and curing bolt connection friction test plate and manufacturing method thereof

A manufacturing method and mobile technology, applied in the direction of spraying device, etc., can solve the problem of not being able to spray the test plate with bolt friction, and achieve the effect of ensuring anti-slip performance, reducing spraying difficulty and improving spraying efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

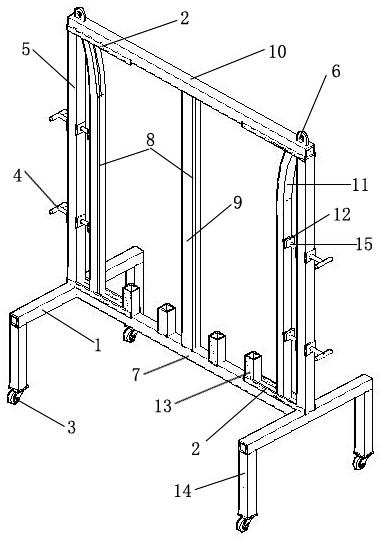

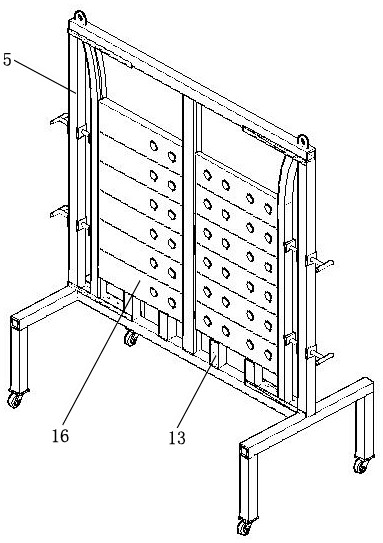

[0026] Such as figure 1 Shown is a movable bracket for spraying and curing bolted friction test plates, including a bracket 1, a support foot 14 is set at the bottom of the support 1, and a universal moving wheel 3 is set on the support foot 14; support columns are set on both sides of the support 1 5, the bracket column 5 is connected with the vertical rod 11 through the screw rod 4; the vertical vertical rod 9 is arranged in the middle of the bracket 1; The pole guide rail 2 is set, the lifting lugs 6 are arranged on both sides of the upper end surface of the upper beam 10, and the test plate spacers 13 are uniformly arranged on the lower beam 10;

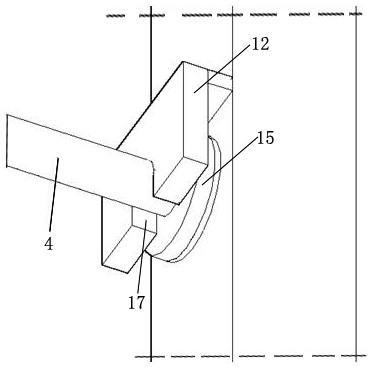

[0027] A top tight iron block 12 is set on the vertical pole 11, and a rubber gasket 15 is set on the top tight iron block 12. The top of the pole 11 is curved. The pole 11 is slidably arranged in the pole guide rail 2 . The support column 5, the vertical pole 9 and the pole 11 are all square tubes.

[0028] A method for manu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com