Deep processing equipment for hydraulic modified asphalt

A modified asphalt and hydraulic technology, which is applied in the field of asphalt deep processing, can solve problems such as inability to mix asphalt uniformly, inconvenient addition of mixture, and poor quality of asphalt, and achieve the effects of preventing clogging, excellent asphalt quality, and uniform and rapid mixing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

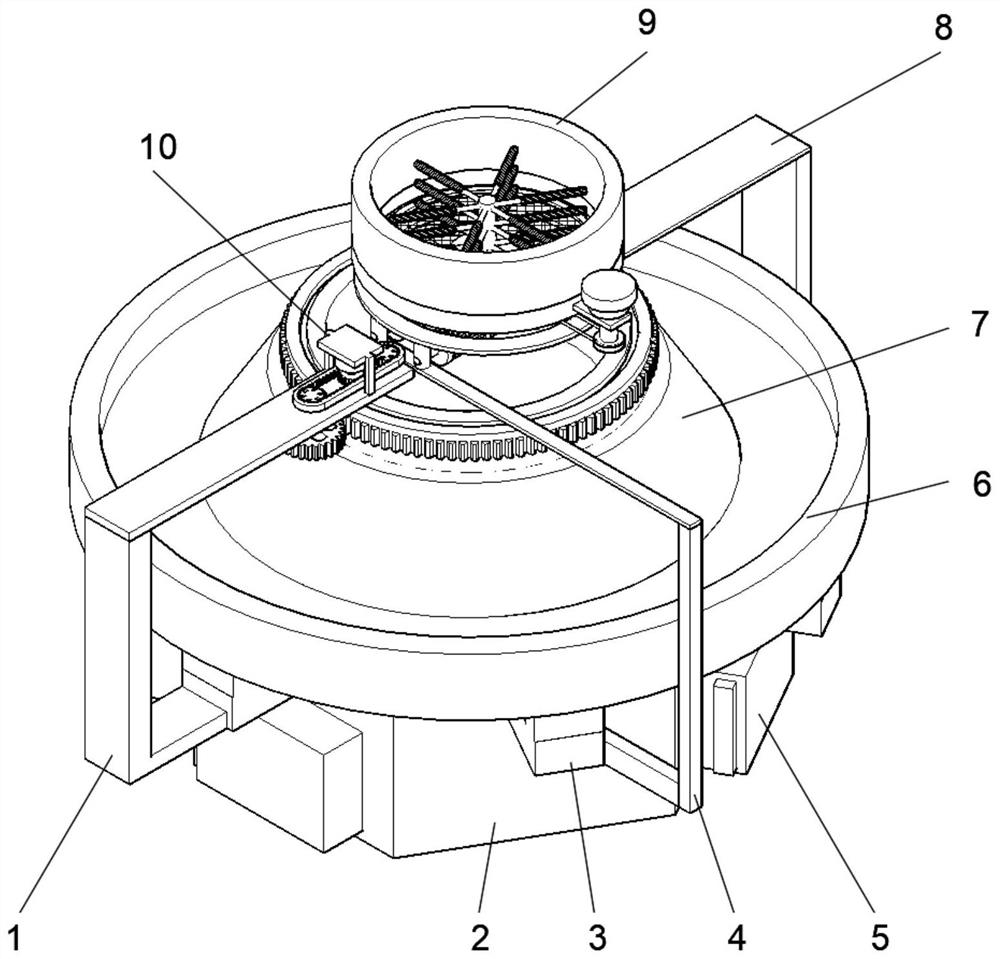

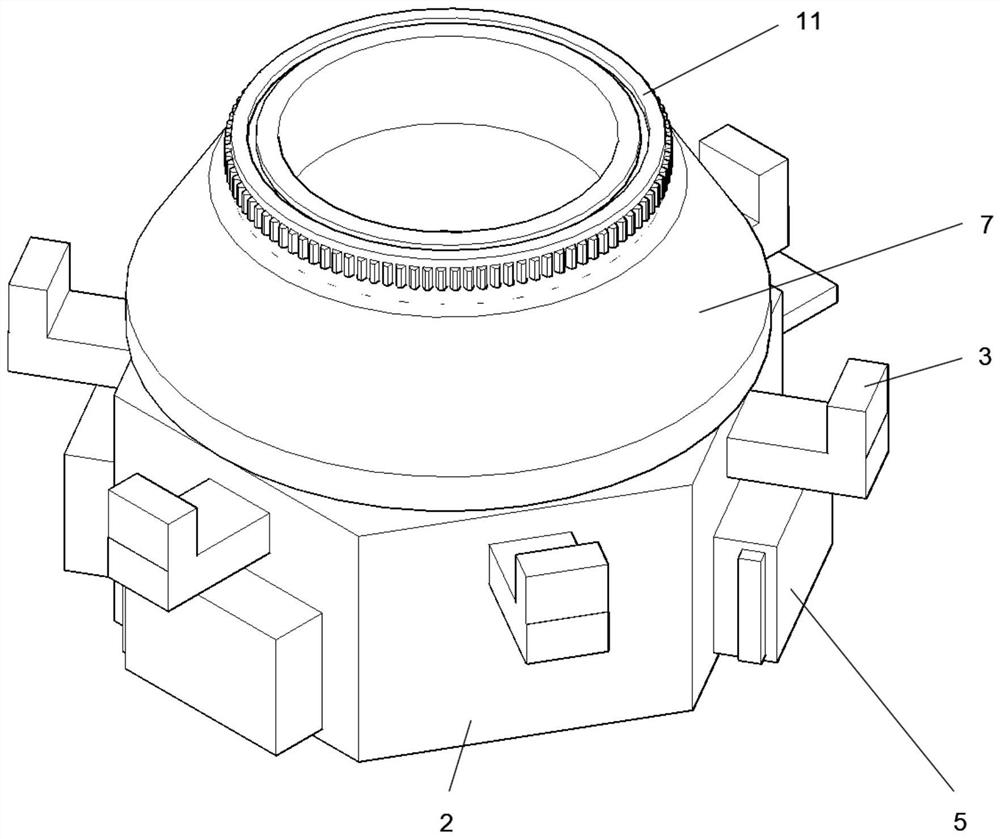

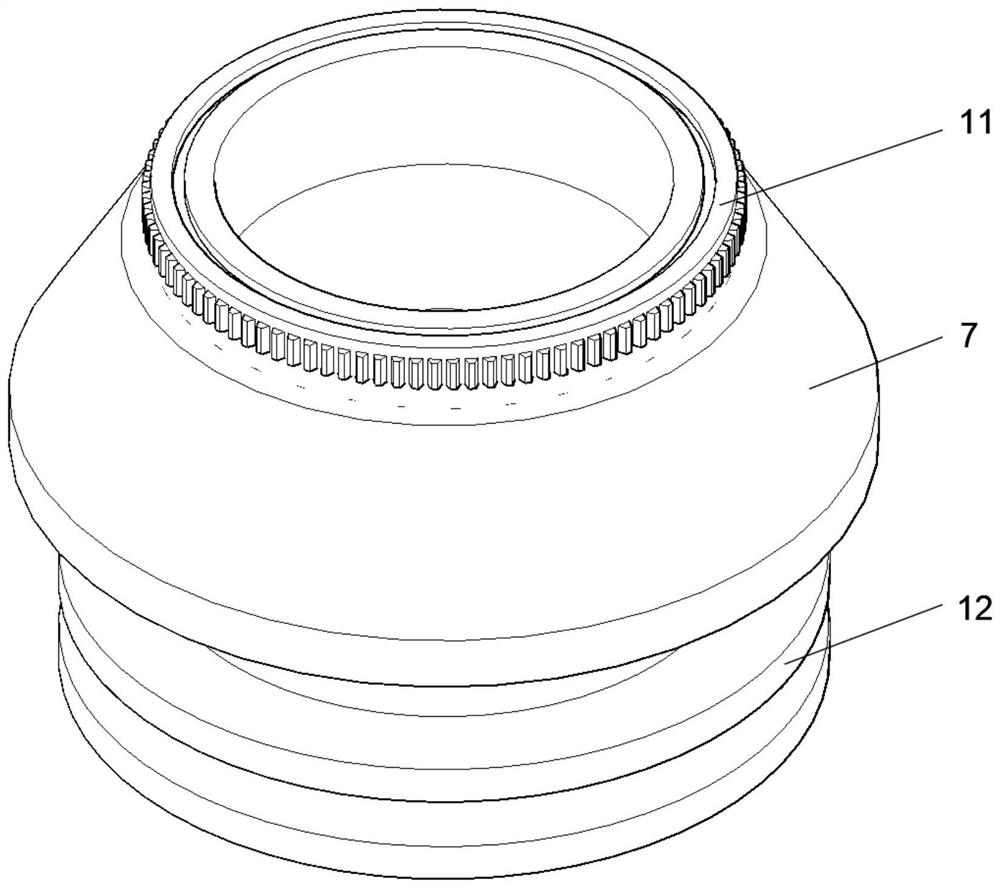

[0036] see figure 1 An embodiment provided by the present invention: a deep processing equipment for hydraulically modified asphalt, including a first fixed support frame 1, a processing pipe body 2, an L-shaped support fixed plate 3, a first connecting frame 4, and a discharge control valve 5. Storage collecting tray 6, stirring and mixing tank 7, second fixed support frame 8, mixing and cleaning mechanism 9 and drive control device 10, stirring and mixing tank 7 is rotatably installed inside the processing pipe body 2, and storing and storing collecting tray 6 is fixed Installed on the upper end of the stirring mixing tank 7, the L-shaped support and fixing plate 3 is evenly fixed and installed between the processing pipe body 2 and the storage collection plate 6, and the discharge control valve 5 is evenly fixed and installed on the middle part of the side end surface of the processing pipe body 2, The first fixed support frame 1 is fixedly installed between the drive contr...

Embodiment 2

[0047] On the basis of Example 1, such as Figure 10 As shown, the edge of the storage collection tray 6 is uniformly fixedly inserted with a discharge pipe 37, and the outer ends of the discharge pipe 37 are threaded and installed with a sealing plug 36, and the discharge pipe 37 is provided with six, and the discharge pipe 37 distributed in a circle.

[0048] When implementing the present embodiment, because the edge of the storage collection tray 6 is uniformly fixedly inserted with a discharge pipe 37, the outer ends of the discharge pipe 37 are threaded and equipped with a sealing plug 36, and the discharge pipe 37 is provided with six, And the discharge pipe 37 is circularly distributed, so the high-temperature asphalt bubbles that continuously flow into the storage collection pan 6 continue to flow out through the discharge pipe 37 before solidification, thereby facilitating the collection of the asphalt collected in the storage collection pan 6. Recycle and reuse.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com