Assembly of tube and pipe tip for applying fluid material

A technology of fluid components and nozzles, which is applied in the direction of surface coating liquid devices, coatings, single handheld devices, etc., can solve the problems of using oil pools, etc., and achieve the effect of accurate coating, ensuring stability, and avoiding rotation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

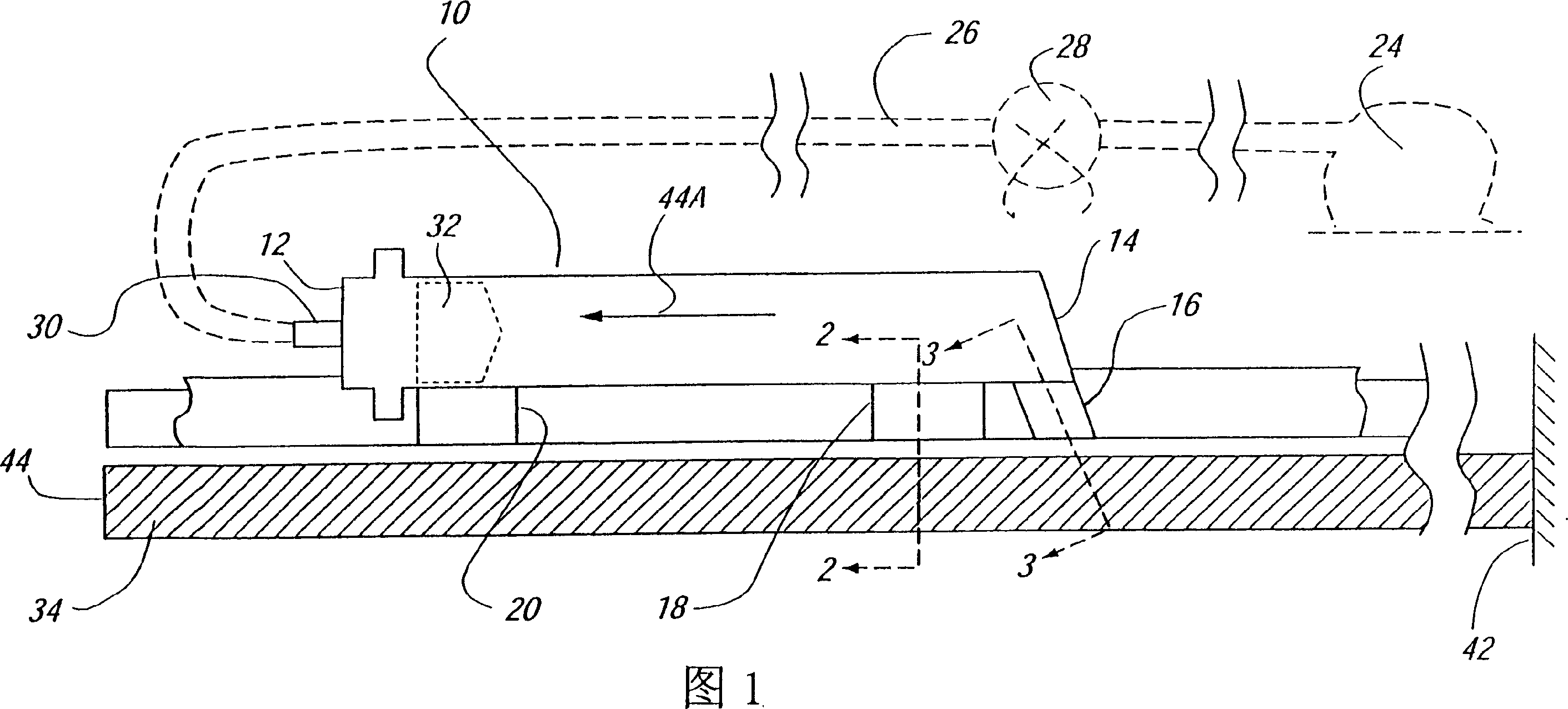

[0032] Referring to the drawings, reference numeral 10 denotes a cartridge for applying a crease-setting composition composed of a thermosetting resin. The barrel is a hollow elongate body and in this embodiment has a circular cross-section, but it may have other cross-sectional shapes as desired. The cartridge has a first end 12 for receiving pressurized fluid, here compressed air, and a second end 14, which is the applicator end of the cartridge, as will be described in more detail below.

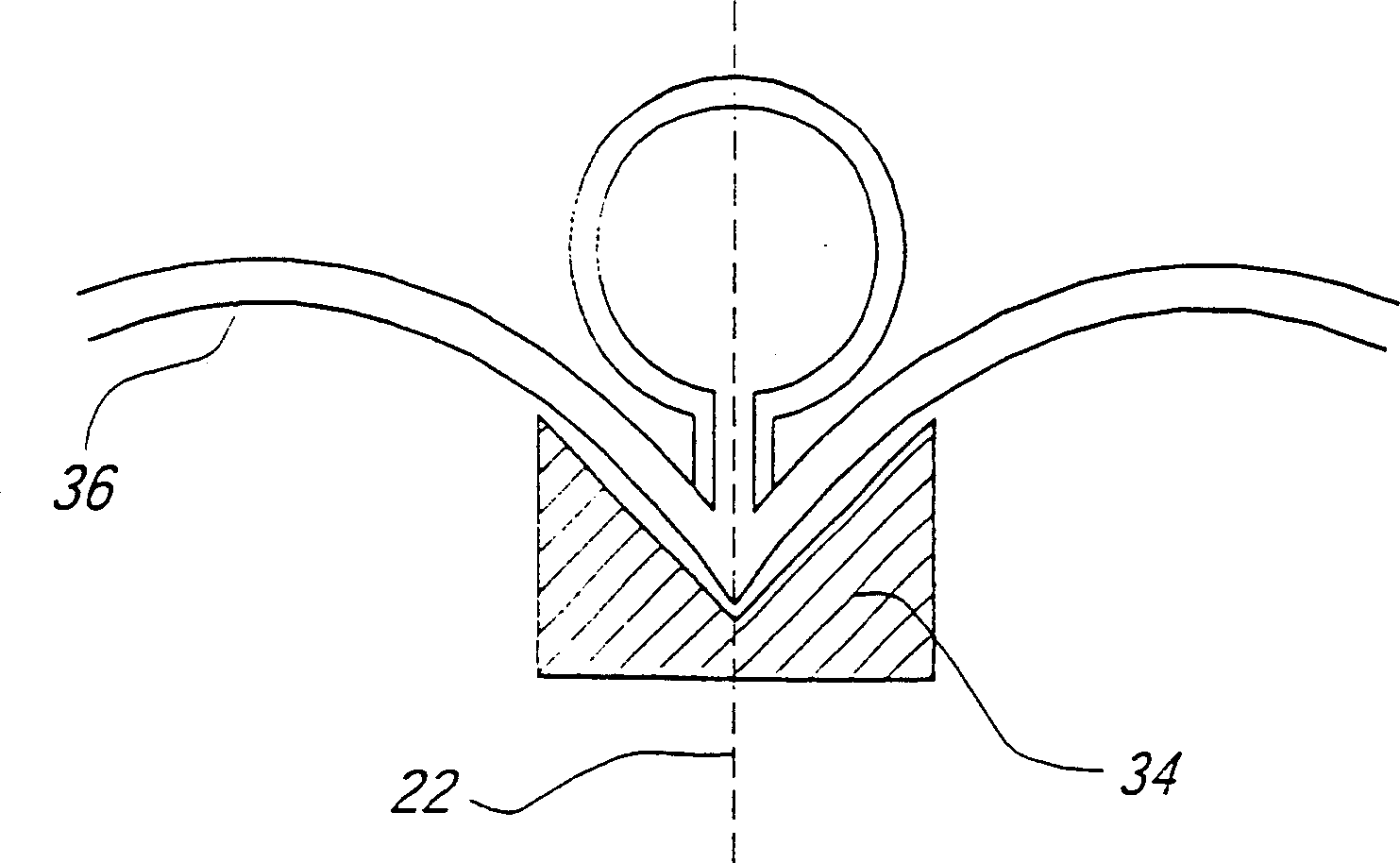

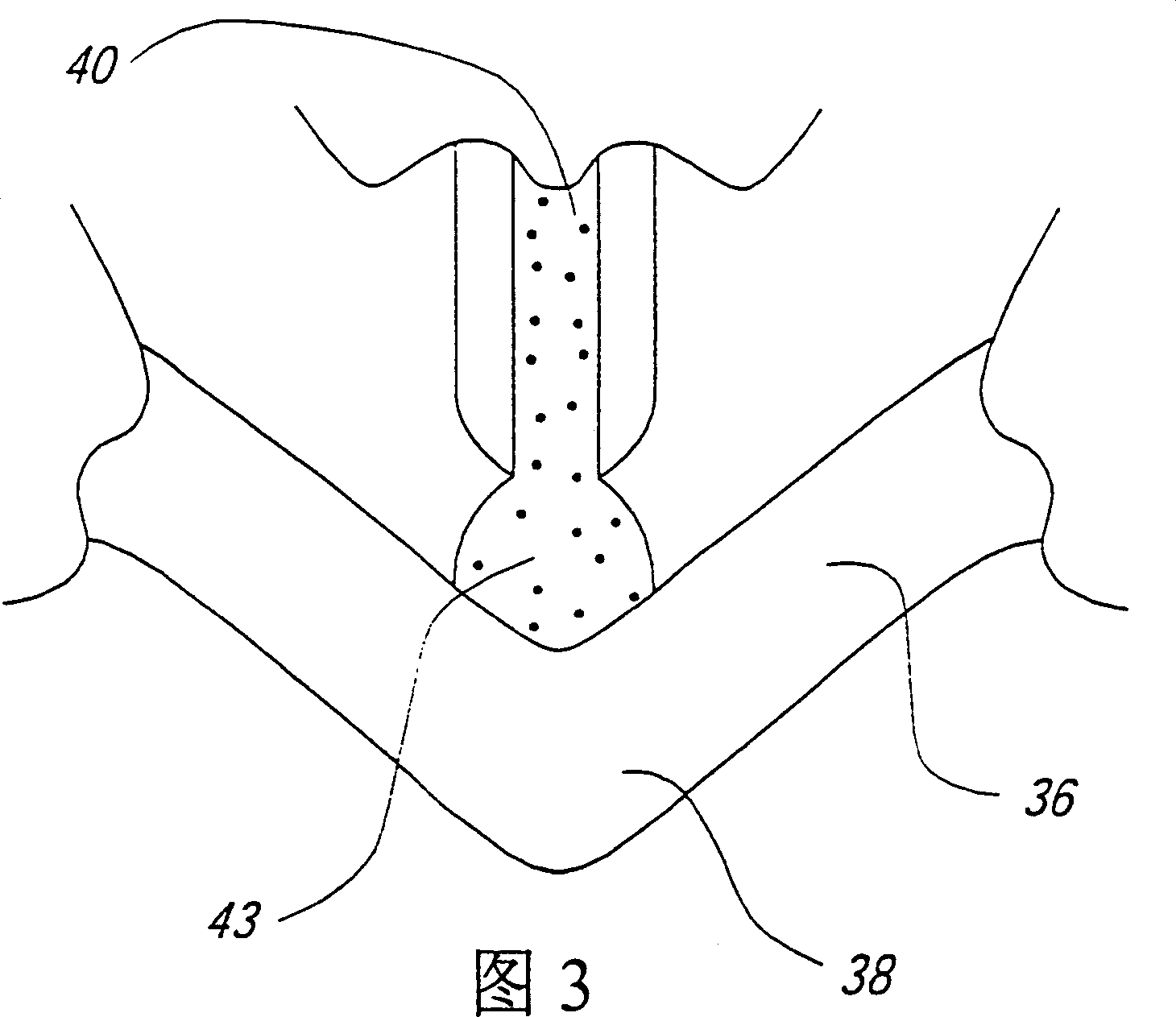

[0033] At the application end, the cartridge has an integral application tongue 16 which, together with a pair of guide slides 18 and 20, lies in a vertical plane of symmetry 22 ( figure 2 )Inside.

[0034] Figure 1 schematically shows a source of compressed air, such as a compressor 24, which supplies compressed air through a line 26 containing a control valve 28 to a fitting 30 at the first end of the cartridge. As will be described below, compressed air will be introduced into the bo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com