Radiation curable inkjet inks for interior decoration

A radiation curing, inkjet ink technology, applied in the field of inkjet ink, can solve problems such as shortened shelf life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

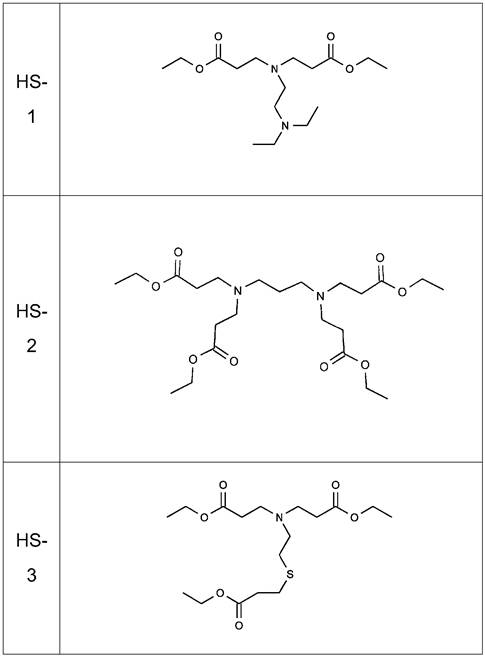

[0325] This example illustrates the synthesis of a singlet oxygen quencher HS-1 to HS-4's.

[0326] Synthetic single-state oxygen quencher HS-1

[0327] 3- [(diethylamino) ethyl 2 - (3-ethoxy-3-oxo-propyl) - amino] propanoate (HS-1) is synthesized according to the following reaction scheme:

[0328]

[0329] The 51.06 g (0.51 mol) of ethyl acrylate was dissolved in 38g of ethanol. The solution was cooled to 0 ℃. Was added 23.24 g (0.2 mol) N, N- diethyl-ethylenediamine solution in 38g of ethanol. The reaction was continued at 0 ℃ 45 minutes. The mixture was heated to 21 ℃ and the reaction was continued for 24 hours at 21 ℃. 5g of ethanol was added a further 5g (0.05mol) acrylate and the reaction was continued for an additional 48 hours. The solvent was removed under reduced pressure and ethyl acrylate excess of HS-1 crude without further purification. HS-1 using LC MS analysis. Since transesterification with ethanol and methanol present, HS-1 of 96.5% of target structures, mono...

Embodiment 2

[0343] This example illustrates the reduction in the aldehyde emissions of the UV cured layer of the radiation-cured ink ink according to the present invention maintained a good shelf life.

[0344] Preparation of Red Dispersion DISP-M

[0345] By using Disperlux from Disperlux S.A.R.L., Luxembourg TM The dispersion was prepared according to the components of Table 5 for 30 minutes. Then, a Bachofen Dynomill ECM grinder grinding dispersion was grinded using a 0.4 mM ruthenium stabilized zirconia bead ("high-resistant zirconium zirconium abrasive medium" from TOSOH Co.). The mixture was circulated on the grinder for 2 hours. After grinding, the concentrated pigment dispersion was discharged into the container through a 1 micron filter.

[0346] table 5

[0347] Component weight% PIG-M 16.94 SYN 0.90 DB162 16.94 Inhiba 1.00 DPGDA 64.22

[0348] Preparation of radiant curing inkjet ink

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface tension | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| refractive index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com