Oil-saving bubble atomization oil gun

A technology of oil gun and air bubbles, which is applied in the field of fuel-saving bubble atomization oil guns, and can solve the problems of easy blockage of oil and gas communication channels and unstable atomization effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

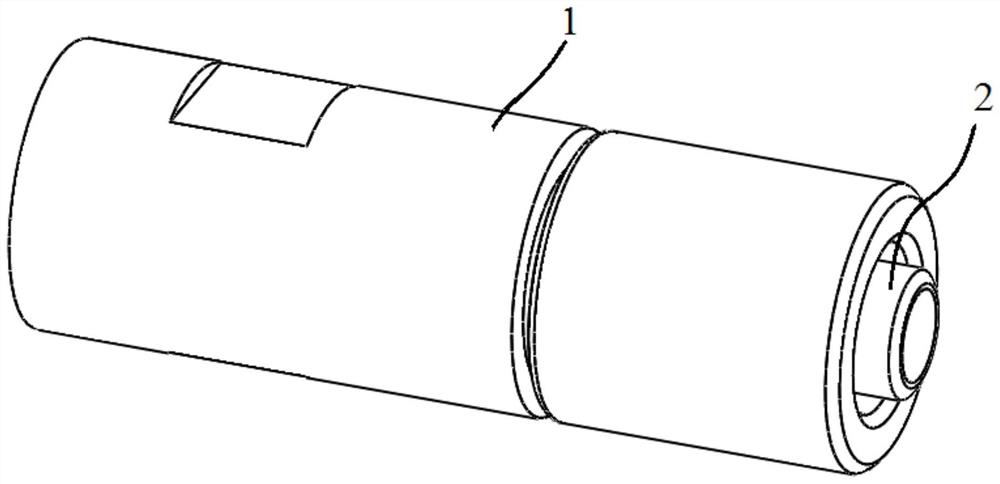

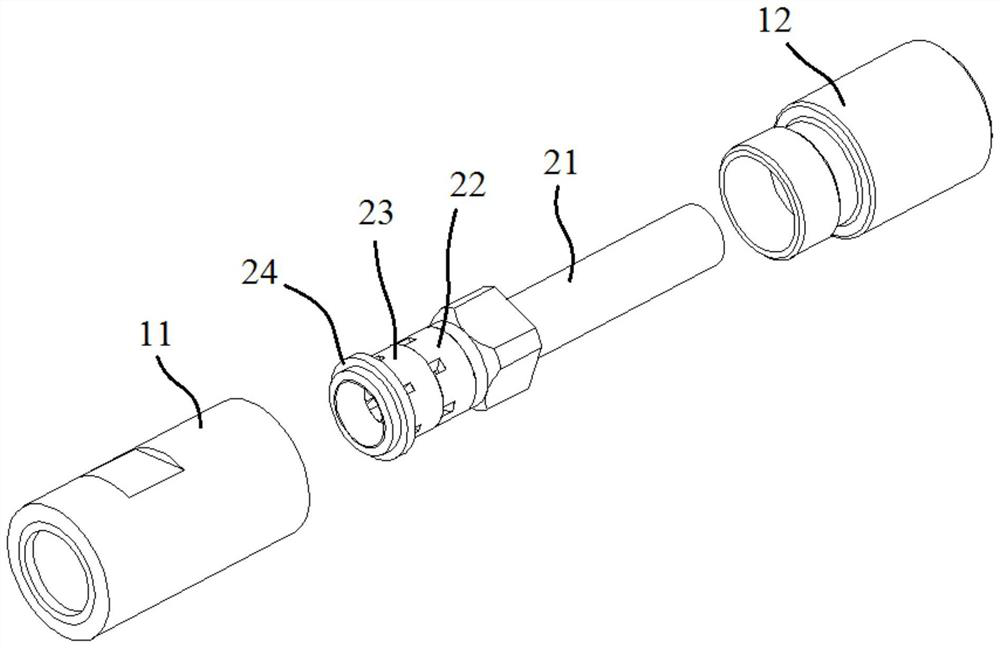

[0040] Such as Figure 1 to Figure 5 As shown, the present application provides a fuel-saving air bubble atomization oil gun, which includes a hollow outer tube 1 and an inner pipeline 2 .

[0041] Wherein, the rear end of the hollow outer tube 1 has an air inlet 1a. In some embodiments, the hollow outer tube 1 can be a single integrated pipe. In a preferred embodiment, the hollow outer tube 1 includes The outer casing 11 and the outer adapter 12 installed in sequence are sealed in communication, wherein the outer casing 11 and the outer adapter 12 are preferably threaded.

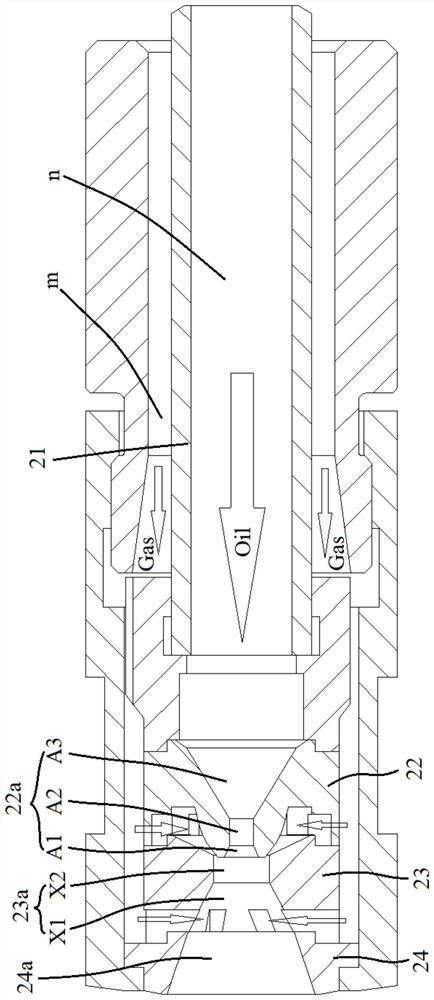

[0042] The inner pipeline 2 is coaxially built inside the hollow outer tube 1 , and an air flow channel m is formed between the hollow outer tube 1 and the inner pipeline 2 .

[0043] In this embodiment, the internal pipeline 2 includes a hollow inner tube 21, a spray head 22 and a first stopper 23, and the hollow inner tube 21 has an oil channel n inside and an oil inlet 21a at the rear end;

[0044] Wh...

Embodiment 2

[0056] Embodiment 2 of the present application provides a fuel-saving air bubble atomization oil gun, the overall structure of which is basically the same as that of Embodiment 1, where the difference lies in:

[0057] Such as Figure 6 and Figure 7 and combine image 3 As shown, the hollow inner tube 21 includes an oil pipe 211 installed in sealed communication and an inner adapter 212. A baffle 213 is formed inside the inner adapter 212. A hole is opened in the middle of the baffle 213. The oil pipe 211 is installed at the rear end of the baffle 213 .

[0058] The internal pipeline 2 also includes an oil mixing block 25, which is coaxially and rotatably installed inside the inner adapter 212 and is located at the front end of the baffle plate 213. The oil mixing block 25 Two oil mixing channels 25a connecting the front and rear ends of the oil mixing block 25 are formed on the outer side of the oil mixing block 25. The oil mixing channels 25a are evenly distributed along...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com