Urea Urea-SCR mixer of diesel internal combustion engine after-treatment system

A diesel internal combustion engine and mixer technology, applied to internal combustion piston engines, exhaust gas treatment, combustion engines, etc., can solve the problems of low ammonia conversion rate and insufficient atomization, and achieve increased mixing time, uniform and sufficient mixing, Improve the effect of the blending effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention is further described below in conjunction with specific embodiment, and specific embodiment is the further description of the principle of the present invention, does not limit the present invention in any way, and the identical or similar technology of the present invention all does not exceed the scope of protection of the present invention.

[0030] In conjunction with the accompanying drawings.

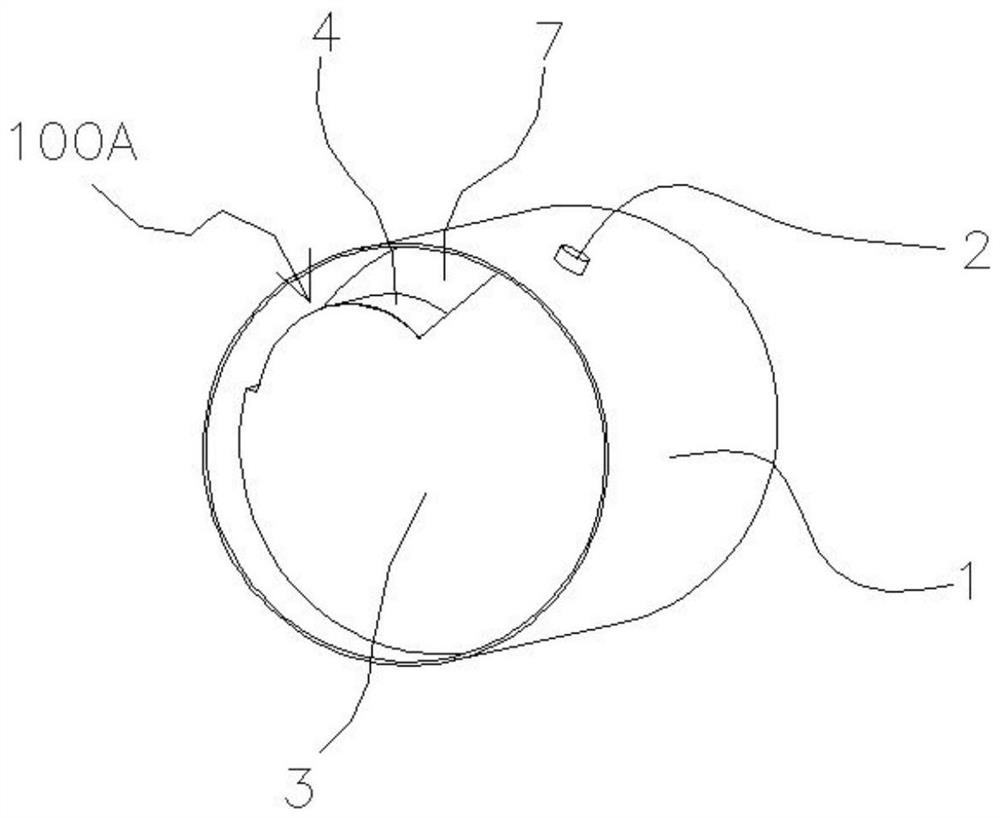

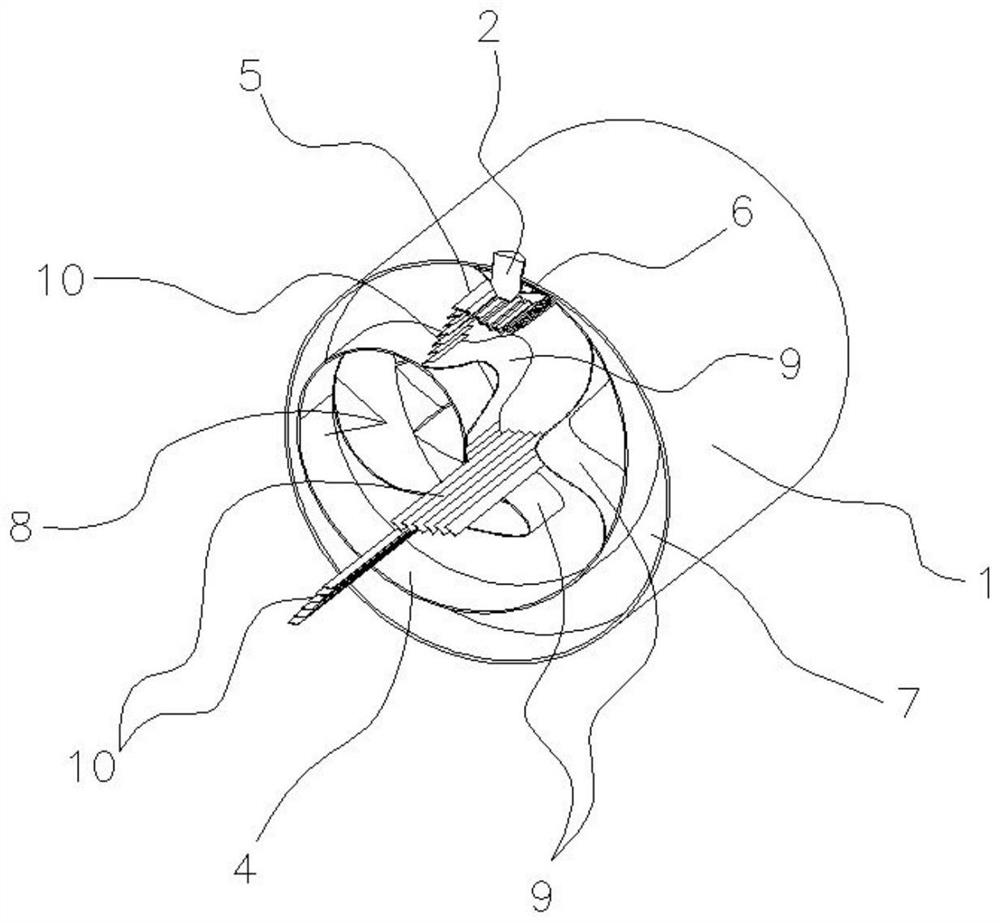

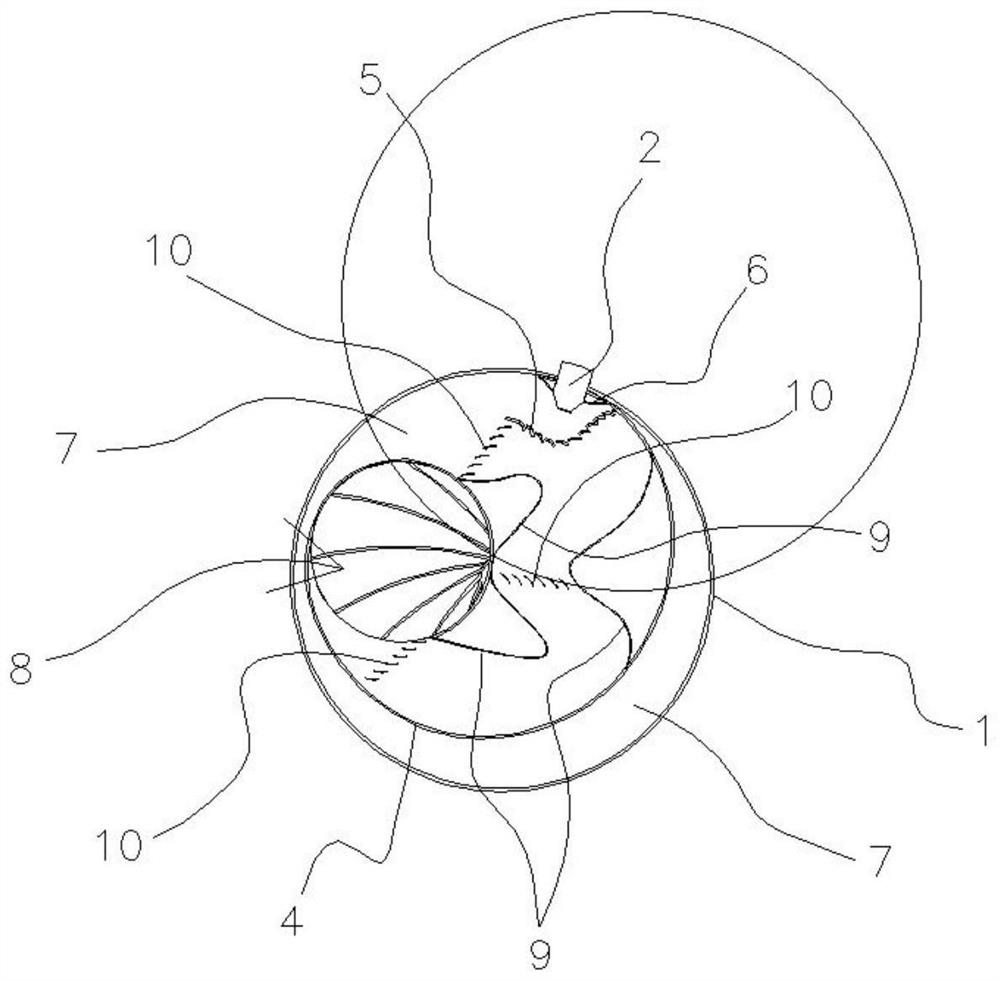

[0031] In this example, the Urea-SCR mixer of the diesel internal combustion engine post-processing system includes: cylinder body 1, urea nozzle mounting seat 2, urea nozzle cover plate 6, air intake end panel 3, air inlet 100A, splitter plate 5, and spiral swirl Deflector 4 , convex-shaped deflector 9 , spoiler grid 10 , air outlet panel 7 , air outlet 8 , flow equalizer 11 .

[0032] An air inlet 100A is formed between the barrel body 1 of the mixer, the air inlet end panel 3 and the spiral swirl deflector 4 .

[0033] The splitter plate 5 is locat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com