A concrete spraying device for material mixing, extrusion and spraying at the same time

A concrete spraying and material technology, which is applied in the processing of building materials, building structures, roads, etc., can solve the problems of restricting the use of special performance concrete, increasing production costs, and consuming time, so as to simplify the spraying construction process and improve production. Efficiency, the effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043]In order to make the technical problems solved by the present invention, the technical solutions adopted and the technical effects achieved more clearly, the present invention will be further described in detail below with reference to the accompanying drawings and embodiments. It should be understood that the specific embodiments described herein are only used to explain the present invention, but not to limit the present invention. In addition, it should be noted that, for the convenience of description, the drawings only show some but not all of the contents related to the present invention.

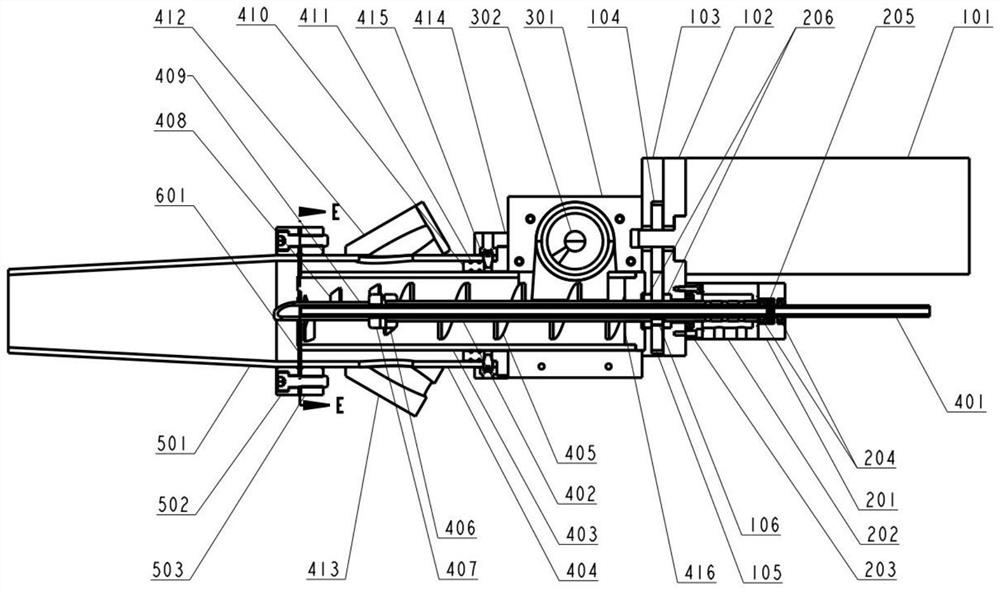

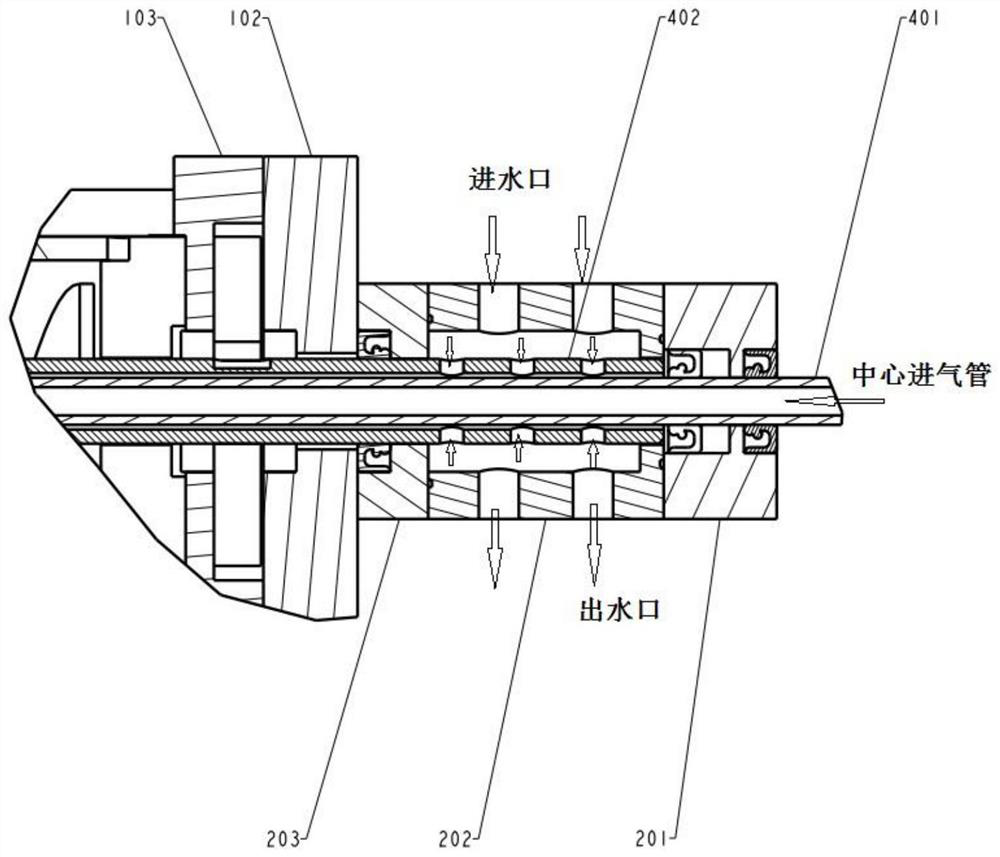

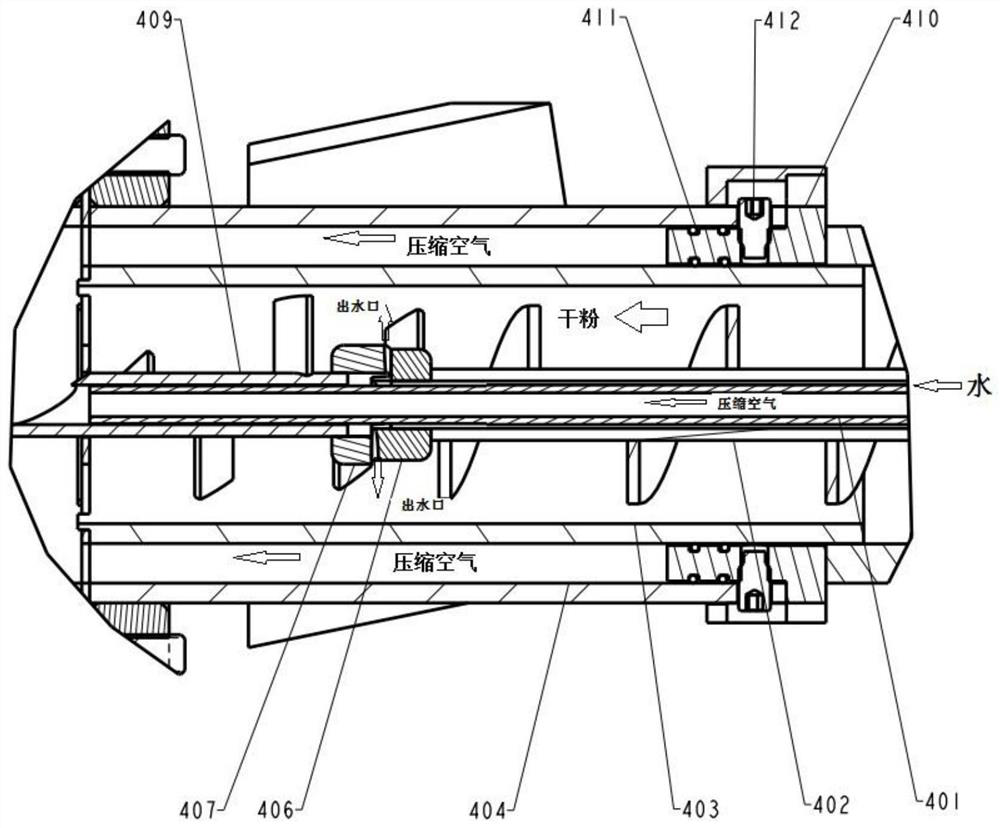

[0044] like Figure 1-3 As shown in the figure, the concrete spraying device for material mixing, extrusion and spraying provided by the embodiment of the present invention includes: a main drive motor 101, a dry powder homogenizing device 302, a water inlet integrated block 202, a powder-liquid stirring pipe 403, a hollow extrusion Outlet shaft 409 , hollow transmission shaft ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com