Ditch type supporting system

A support system and ditch technology, applied in excavation, construction, foundation structure engineering, etc., can solve problems such as loose steel sheet piles, no pre-tightening function of support rods, and poor service conditions of the support system, so as to increase the contact surface and improve Acceptance status, effect of good control of foundation pit deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

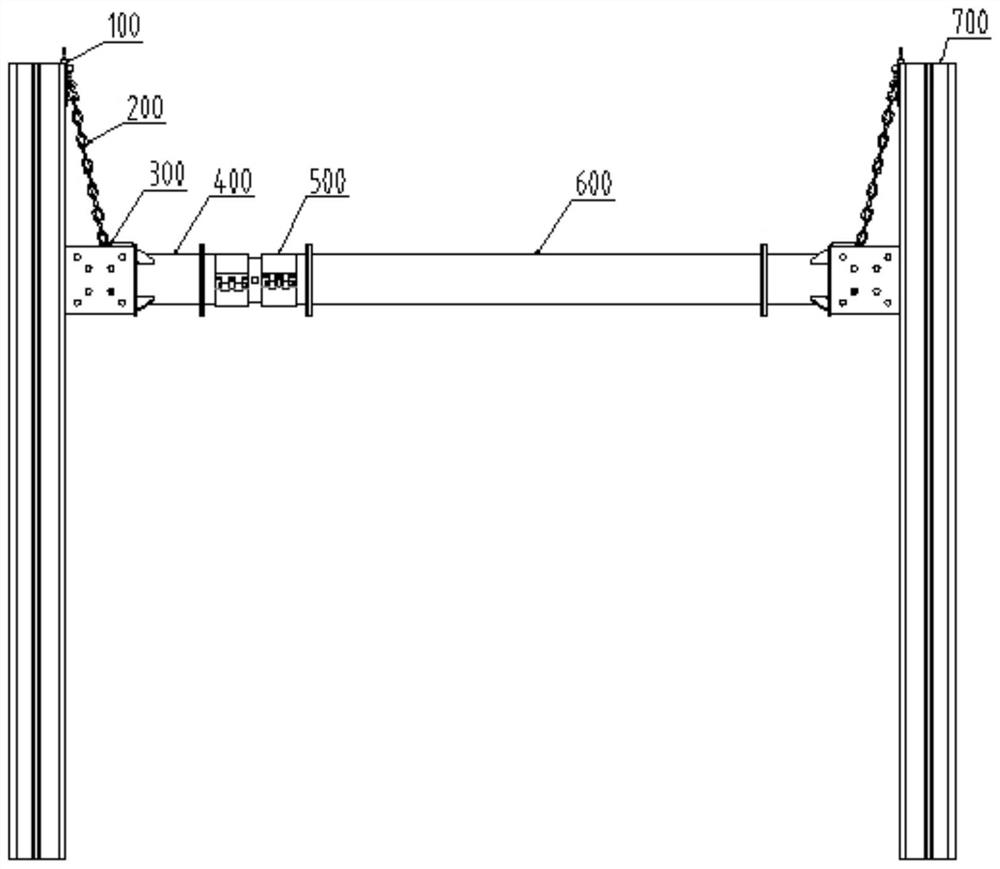

[0054] In further embodiments of the present invention, please continue to refer to Figure 1 to Figure 9 As shown, the first connecting piece 400 also includes: a first steel pipe 430 and a first hanging plate 410 arranged at one end of the first steel pipe 430, the first hanging plate 410 is welded together with one end of the first steel pipe 430, the first hanging plate 410 is also provided with laps (not marked), so that it is more convenient to fix the first hanging plate 410 on the corresponding purlin 300, reducing the operation process, and several steel pipes 430 are also provided on the first steel pipe 430 for strengthening The first rib 420 and the fourth rib 450 of the overall structural strength of the first connecting piece 400 prolong the service life of the first connecting piece 400 .

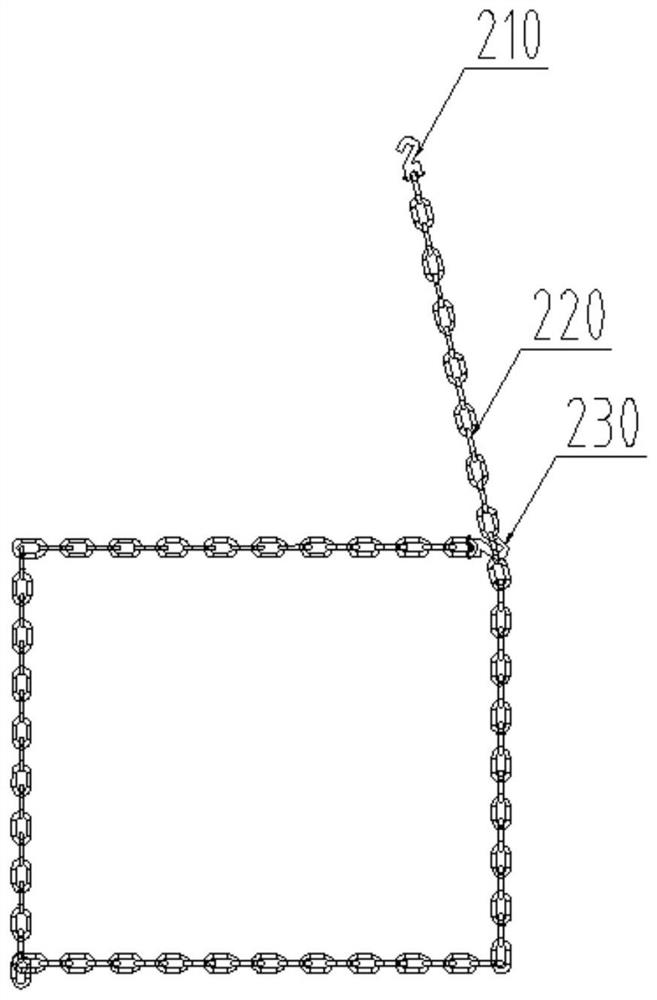

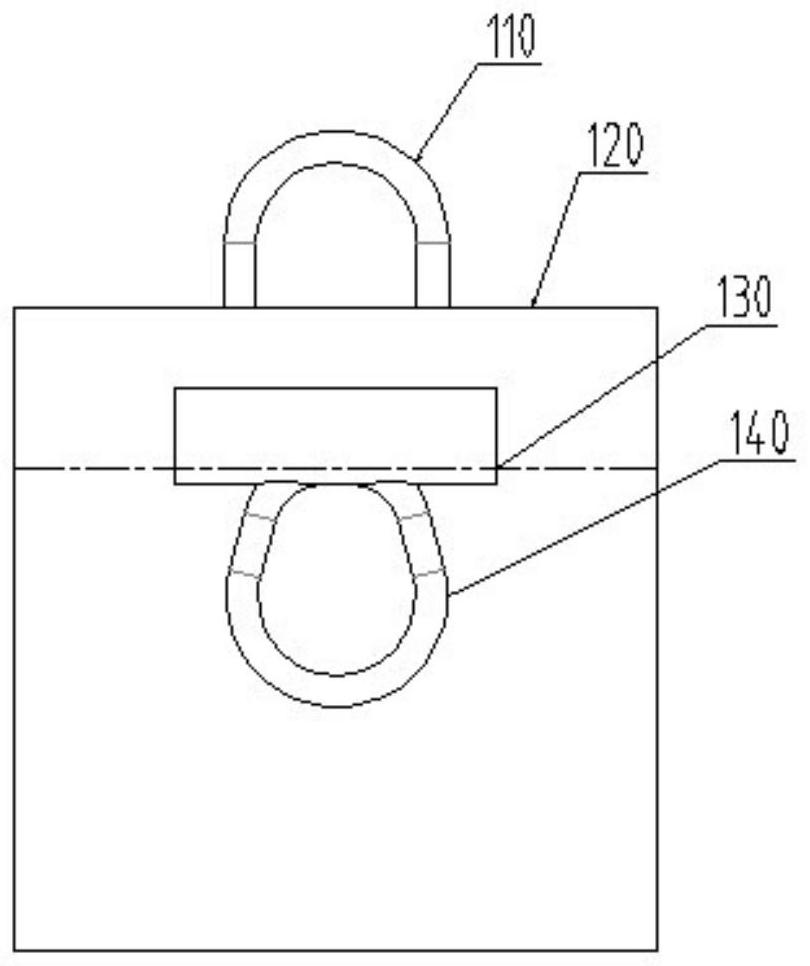

[0055] Further, as a preferred embodiment, each group of spreader components includes: a second hanging plate 100 and a chain 200, the second hanging plate 100 is arranged on...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com