Organic cotton denim with knitted fabric effect and preparation method thereof

A technology of organic cotton and denim, applied in knitting, weft knitting, fabric surface trimming, etc., can solve the problems of affecting the smoothness and hand feeling of cotton knitted fabrics, affecting the processing efficiency of fabrics, and prolonging the fabric processing cycle to achieve excellent anti-corrosion Yellowing ability, excellent appearance after washing, and smooth hand feeling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

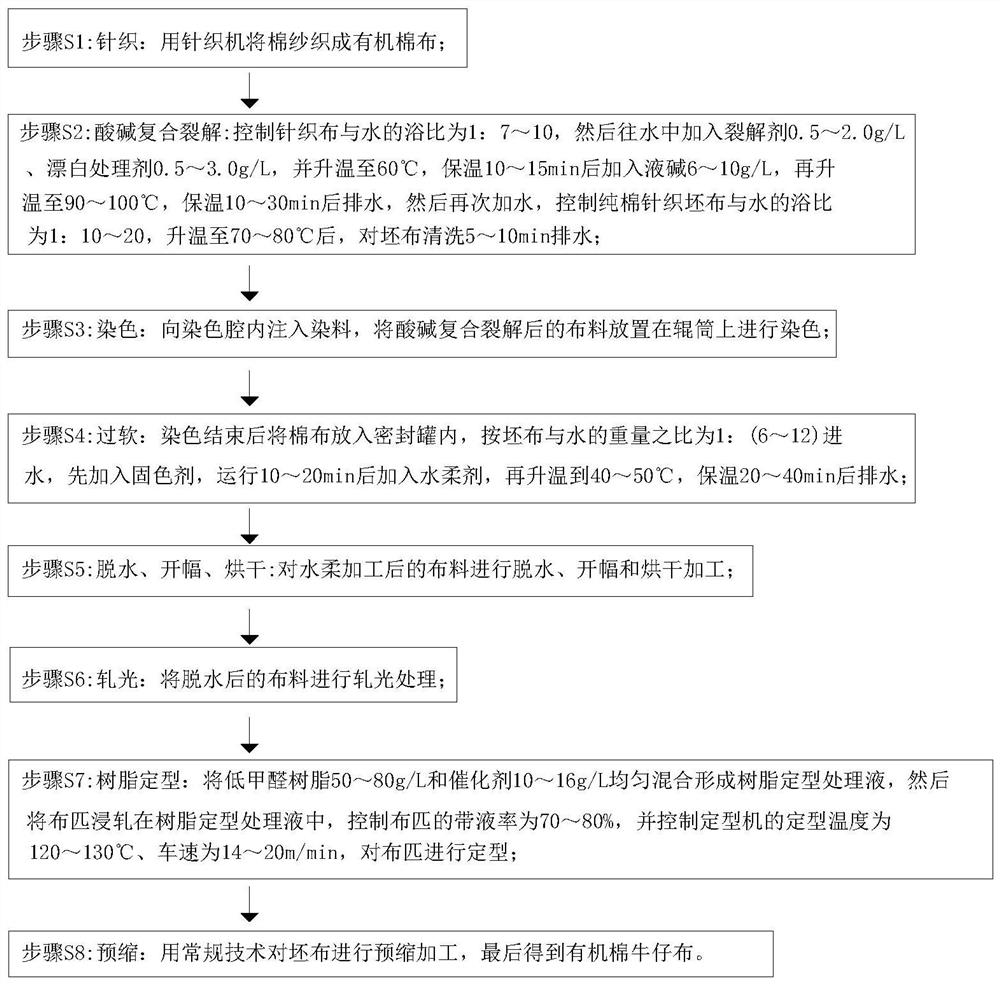

[0029] A method for preparing organic cotton denim with knitted fabric effect, comprising the following steps:

[0030] Step S1: knitting: knitting cotton yarn into organic cotton cloth with a knitting machine;

[0031] Step S2: acid-base compound cracking: control the bath ratio of knitted fabric and water to 1:7-10, then add 0.5-2.0 g / L cracking agent and 0.5-3.0 g / L bleaching agent to the water, and heat up to 60 ℃, keep warm for 10-15 minutes, add liquid caustic soda 6-10g / L, then raise the temperature to 90-100 ℃, keep warm for 10-30 minutes, drain water, then add water again, control the bath ratio of pure cotton knitted gray fabric to water as 1:10~ 20. After heating up to 70-80°C, wash the gray cloth for 5-10 minutes and drain water;

[0032] Step S3: Dyeing: injecting dye into the dyeing cavity, placing the cloth after acid-base compound cracking on the roller for dyeing;

[0033] Step S4: Too soft: after dyeing, put the cotton cloth into the airtight tank, accordin...

Embodiment 2

[0039] A method for preparing organic cotton denim with knitted fabric effect, comprising the following steps:

[0040] Step S1: knitting: knitting cotton yarn into organic cotton cloth with a knitting machine;

[0041] Step S2: acid-base compound cracking: control the bath ratio of knitted fabric and water to 1:5-8, then add cracking agent 0.3-1.8g / L, bleaching agent 0.4-2.8g / L to the water, and heat up to 50 ℃, keep warm for 5-8 minutes, add liquid caustic soda 5-8g / L, then raise the temperature to 90-100 ℃, drain water after keeping warm for 8-20 minutes, and then add water again, control the bath ratio of pure cotton knitted gray fabric and water to 1:8~ 15. After heating up to 70-80°C, wash the gray cloth for 5-10 minutes and drain water;

[0042] Step S3: Dyeing: injecting dye into the dyeing cavity, placing the cloth after acid-base compound cracking on the roller for dyeing;

[0043] Step S4: Too soft: after dyeing, put the cotton cloth into the airtight tank, enter ...

Embodiment 3

[0049] A method for preparing organic cotton denim with knitted fabric effect, comprising the following steps:

[0050] Step S1: knitting: knitting cotton yarn into organic cotton cloth with a knitting machine;

[0051] Step S2: acid-base compound cracking: control the bath ratio of knitted fabric and water to 1:6-9, then add cracking agent 0.4-1.9g / L, bleaching agent 0.3-3.2g / L into the water, and heat up to 60 ℃, keep warm for 8-20min, add liquid alkali 8-12g / L, then raise the temperature to 80-90℃, drain water after keeping warm for 12-28min, then add water again, control the bath ratio of pure cotton knitted gray fabric to water as 1:9~ 25. After heating up to 60-90°C, wash the gray cloth for 3-12 minutes and drain water;

[0052] Step S3: Dyeing: injecting dye into the dyeing cavity, placing the cloth after acid-base compound cracking on the roller for dyeing;

[0053] Step S4: Too soft: after dyeing, put the cotton cloth into the airtight tank, according to the weight ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com