Full-automatic cooker

A cooking machine, fully automatic technology, applied in household heating, heating methods, lighting and heating equipment, etc., can solve the problems of energy saving, unsanitary, environmental protection, etc., to ensure the stir-frying effect, reduce oil stains, and improve taste Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

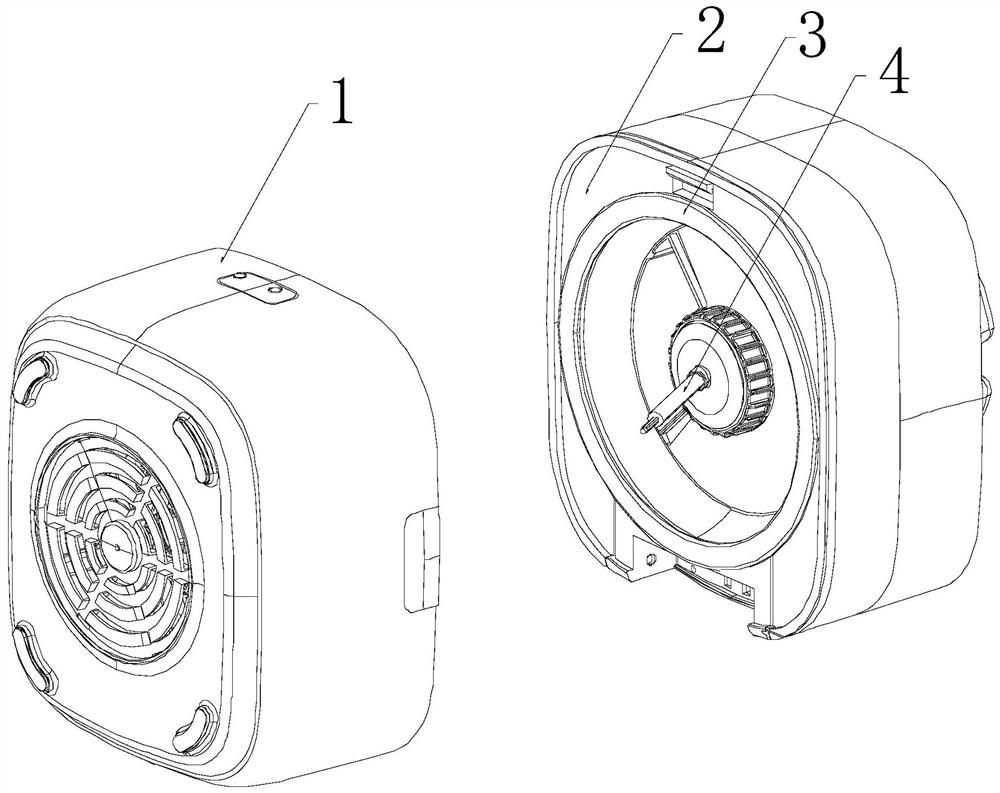

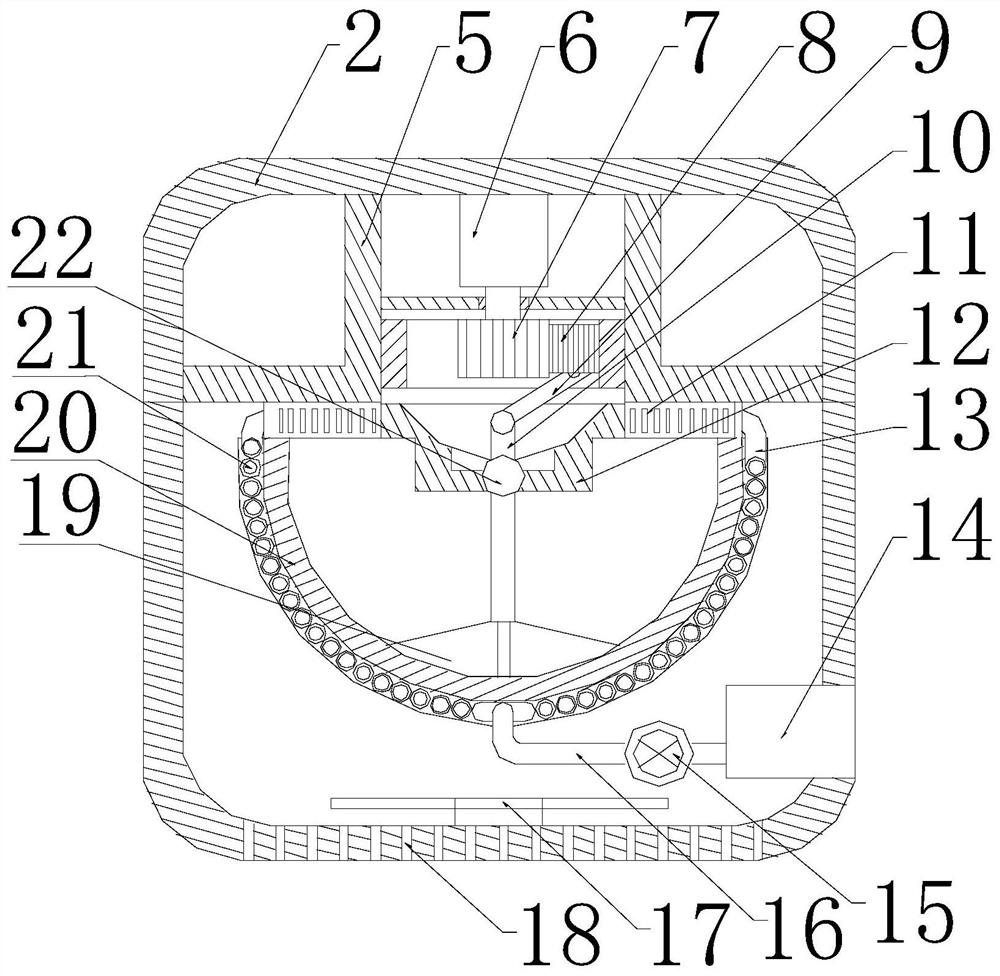

[0026] Such as Figure 1~5 As shown, this embodiment includes an upper casing 2 and a lower casing 1 hinged to each other, a sealing ring 3 is provided on the inner wall of the upper casing 2, and a fixed cavity 5 is provided in the upper casing 2 to fix The cavity 5 is provided with a motor 6 and an internal gear. The output end of the motor 6 is provided with a main gear 7. The main gear 7 meshes with the internal gear through a secondary gear 8. A connecting rod 9 is hingedly arranged on the end face of the secondary gear 8. The lower end of the fixed cavity 5 is provided with a base 12, and a spherical cavity is provided on the lower end surface of the base 12, and a ball head 22 cooperating with it is provided in the spherical cavity, and the upper end and the lower end of the ball head 22 respectively protrude from the spherical cavity, The upper end of the ball head 22 is provided with a linkage rod 10 hinged with the connecting rod 9, the lower end of the ball head 22 ...

Embodiment 2

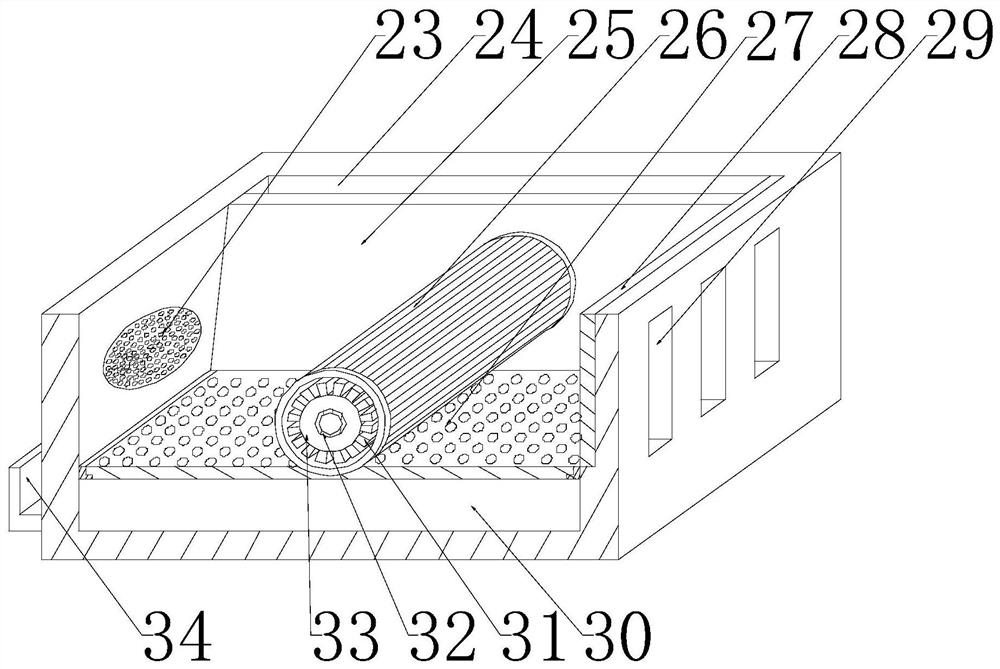

[0032] Such as Figure 1~5 As shown, after using this embodiment for a period of time, a certain amount of oil stains will accumulate in the exhaust cavity, which needs to be cleaned regularly. The cleaning pipe 32 is placed in the middle of the rotating shaft 33, and when the smoke is exhausted, the cleaning pipe 32 It is in a closed state, that is, no cleaning liquid is injected. When the motor 6 is stopped, the liquid injection port of the cleaning pipe 32 located in the adjustment chamber is opened, and the cleaning liquid flowing at a high speed is injected into the cleaning pipe 32, and the cleaning liquid passes through the liquid outlet. 39 is ejected outward, and because the roller 26 is set for rotation, the ejected cleaning liquid can directly act on the roller 26, and the roller 26 can be driven by the ejected cleaning liquid, thereby realizing the rotation of the roller 26 and rotating The roller 26 can sprinkle the cleaning liquid on the inner wall of the trapezo...

Embodiment 3

[0035] Such as figure 2 with Figure 5 As shown, the interior of the liquid storage cylinder 14 in this embodiment is provided with a cavity, the liquid outlet of the pump 15 communicates with the interior of the cavity, and a baffle 35 is provided above the inner wall of the cavity, and the baffle 35 is arranged along the row. The air direction is arranged obliquely from top to bottom, and there are a plurality of air outlets 36 on the side wall of the liquid storage cylinder 14 facing away from the suction and discharge pipe 13, and a liquid discharge port is opened on the side wall of the liquid storage cylinder 14. The liquid port is located below the air discharge port 36, and a plug 37 is provided on the liquid discharge port. After entering the tail pipe 16 from the heat collecting tube, the tail pipe 16 has a certain length after being folded, so that the water vapor in the flue gas can be gradually liquefied, and when the used flue gas enters the cavity through the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com