Cleaning equipment used before steak processing

A technology for cleaning equipment and steaks, which is applied in the direction of meat processing equipment, processed meat, applications, etc., can solve the problems of increasing the economic cost of the device, consuming a lot of manpower and time and energy, and cleaning dead corners, so as to improve the washing effect and save the economy Cost, the effect of preventing cleaning dead ends

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

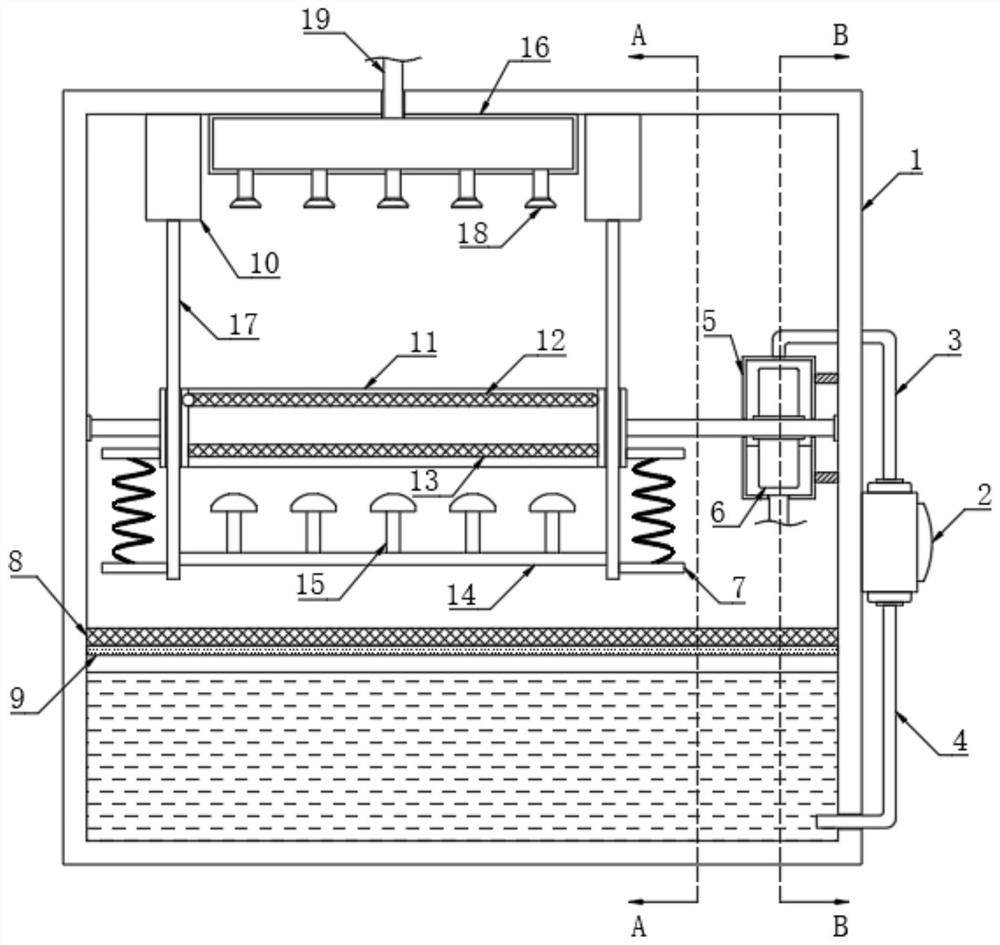

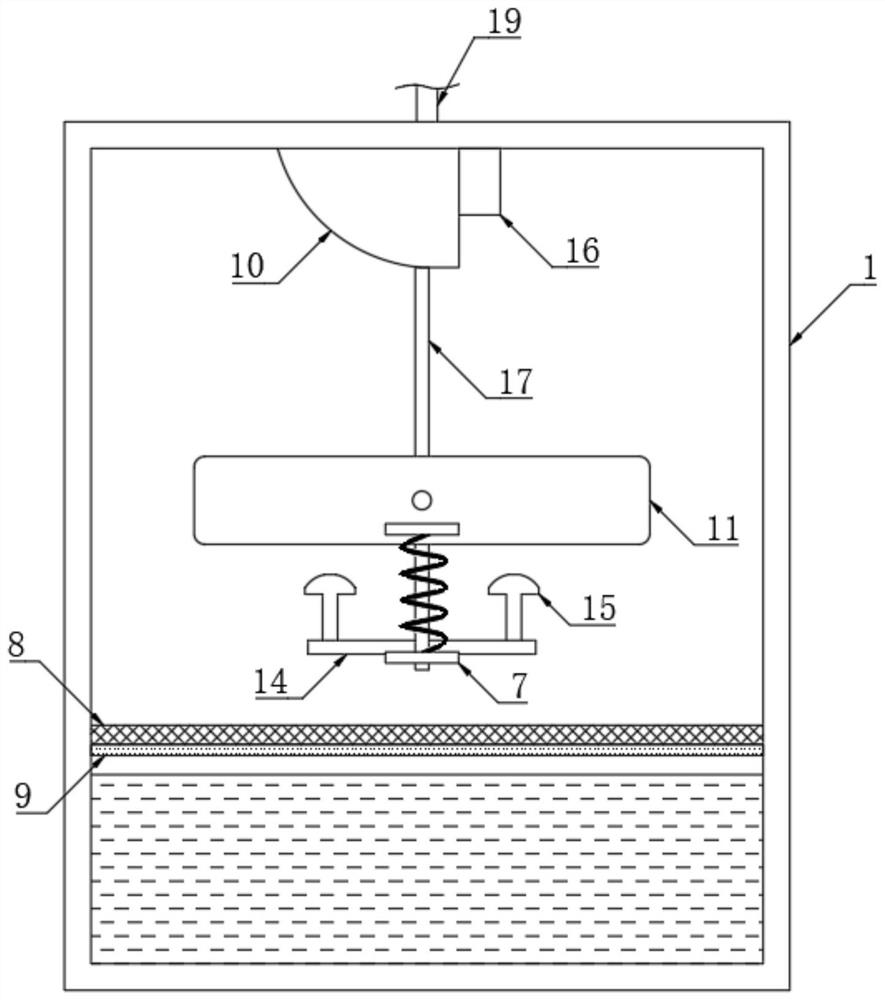

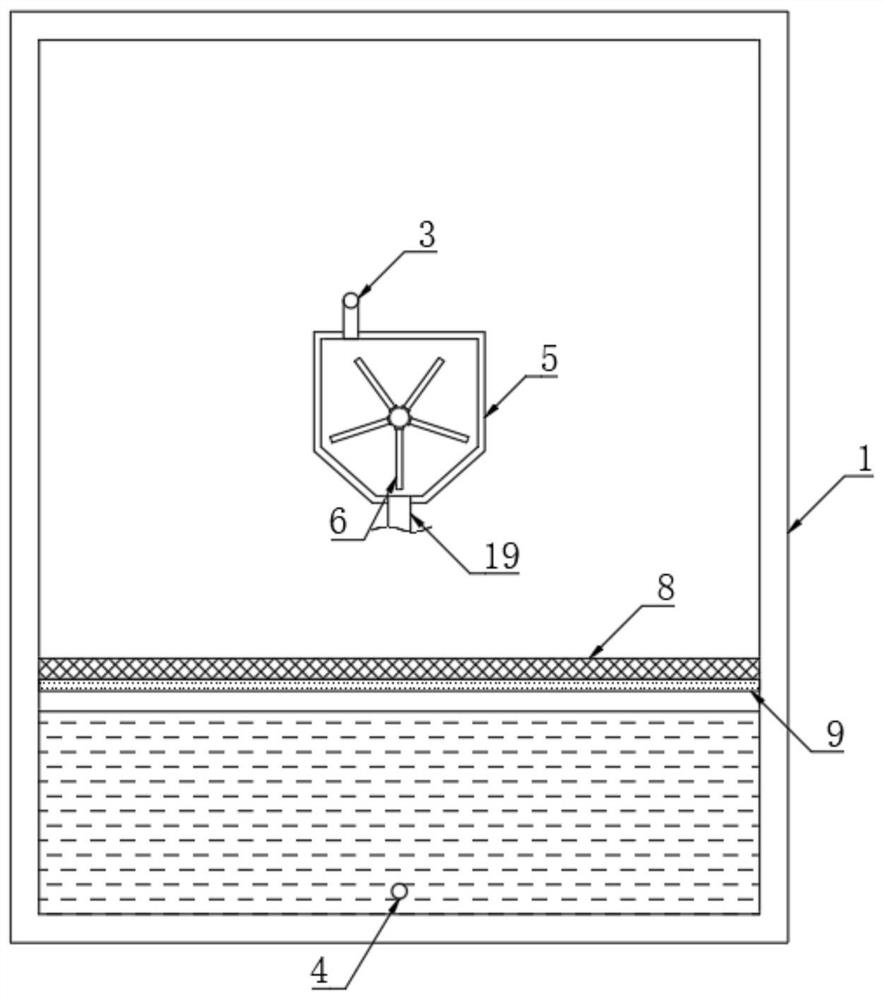

[0031] refer to Figure 1-4 , a cleaning device for steak processing, comprising a cleaning box 1, the inner wall of the cleaning box 1 is fixedly connected with a filter 8, the filter 8 is used to filter solid impurities in the water after cleaning, and the inner wall of the cleaning box 1 is fixedly connected with a grease filter Membrane 9, grease filter membrane 9 can filter out the grease in the water after cleaning.

[0032] The cleaning box 1 is provided with a placement mechanism for placing steaks. The placement mechanism includes a placement frame 11 arranged in the cleaning box 1. The inner wall of the cleaning box 1 is rotatably connected with a thin rod, and the thin rod is fixedly connected with the side wall of the placement frame 11. The placement frame The side wall of the 11 inner ring is fixedly connected with a fixed screen 13, and the side wall of the inner ring of the placement frame 11 is provided with a rotating screen 12 that can rotate. Existing tech...

Embodiment 2

[0040] refer to Figure 5 The difference between this embodiment and Embodiment 1 is that permanent magnet blocks 21 are fixedly connected to the opposite side walls of the two moving rods 17 , and metal rings 20 are fixedly connected to the side walls of multiple conduits.

[0041] Compared with Embodiment 1, in this embodiment, the rotation of the moving rod 17 will drive the permanent magnet block 21 to rotate. When the permanent magnet block 21 rotates to the upper end close to the metal ring 20, it will attract the metal ring 20 to approach it, thereby driving the catheter Swing, when the permanent magnet block 21 is far away from the metal ring 20, the metal ring 20 is no longer attracted, and the conduit will be in a vertical state again. Repeat the above operation. During the cleaning process, the conduit can swing back and forth, and then drive multiple nozzles 18 Swing back and forth, thereby changing the spraying position of the nozzle 18, expanding the cleaning ran...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com