Rapid assembly tool for new energy automobile connector production

A new energy vehicle and assembly tooling technology, which is applied in the assembly/disassembly of contact parts, vehicle connectors, etc., can solve the problems of low production efficiency, low quality of connector production and assembly, and many assembly stations, so as to improve assembly production efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

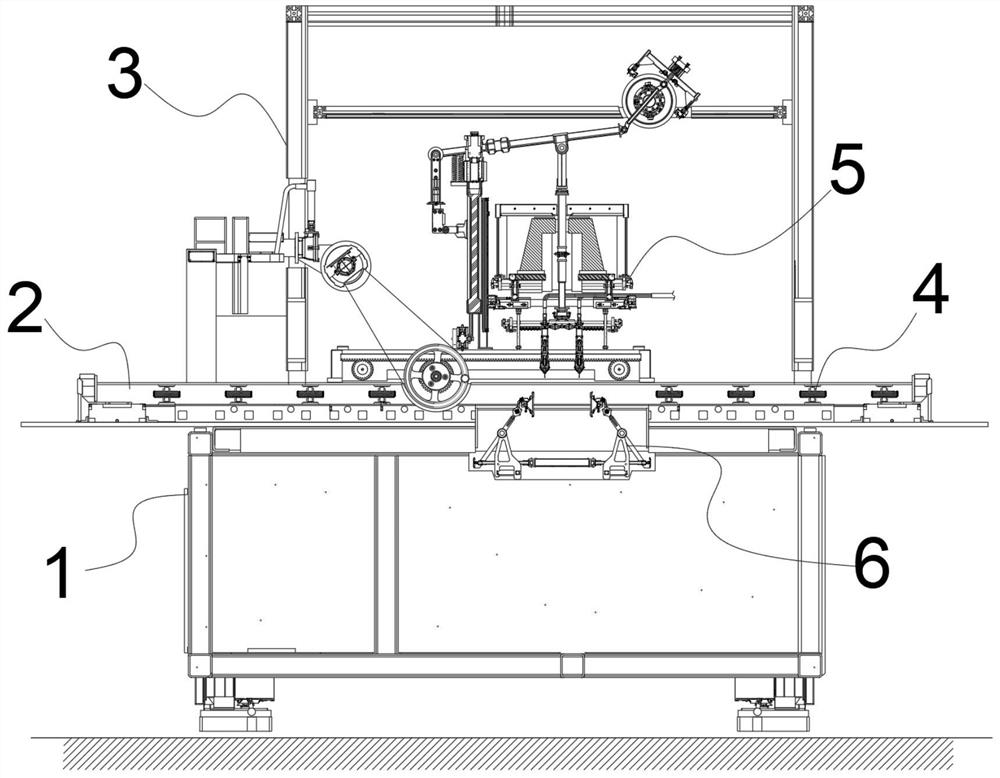

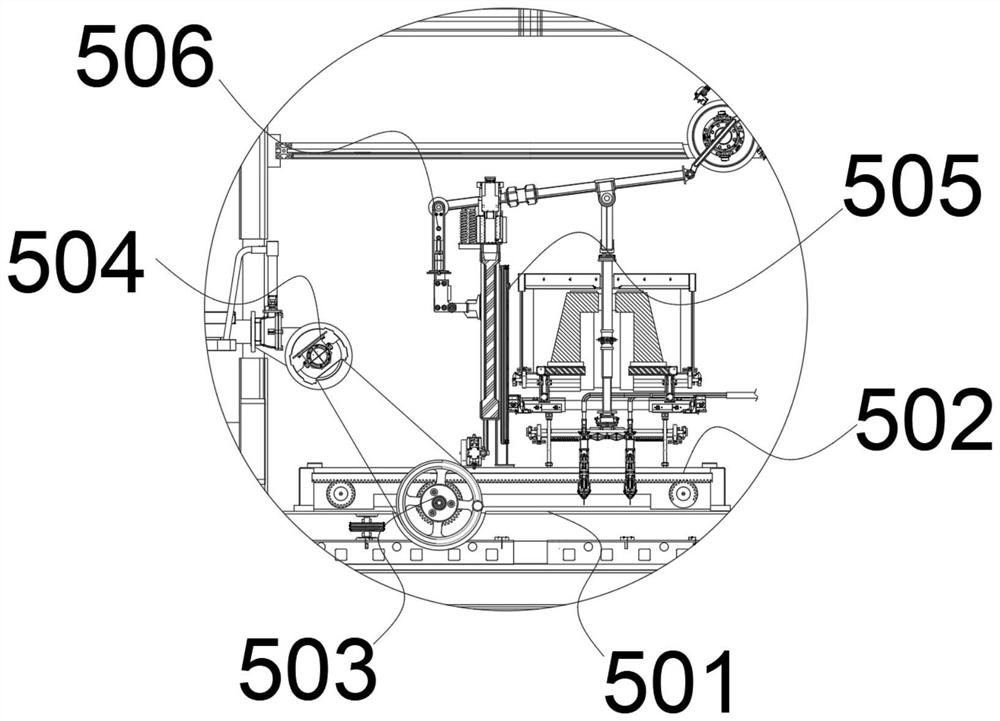

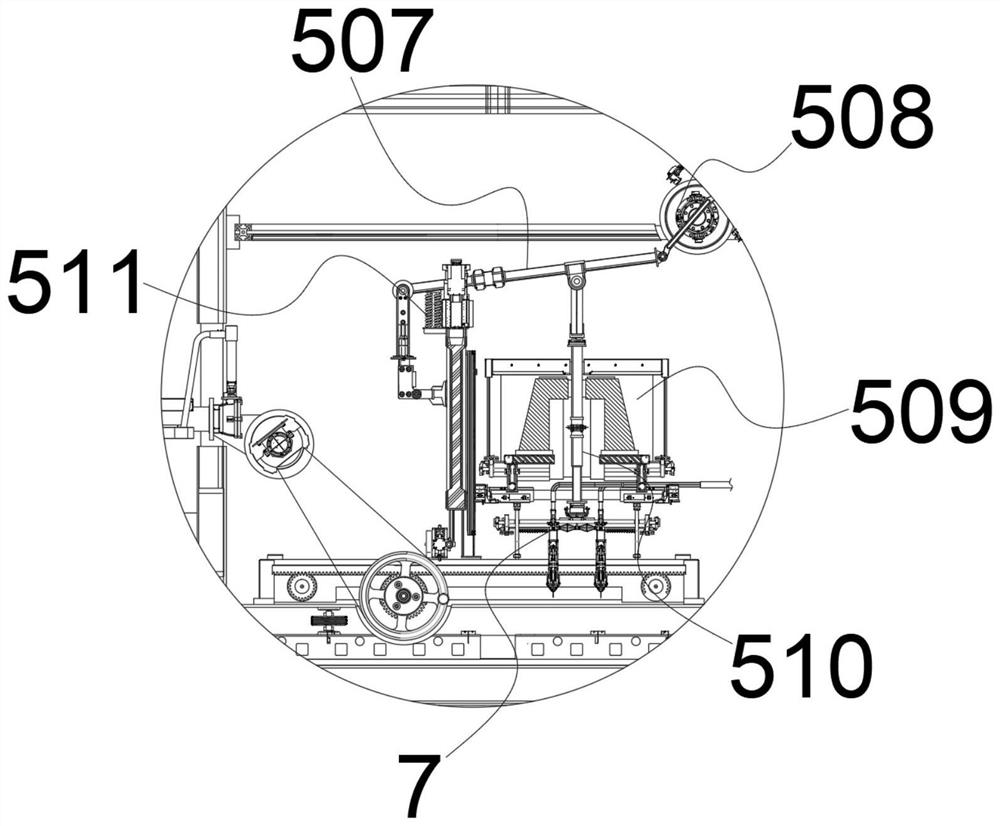

[0038] see figure 1 , in an embodiment of the present invention, a quick assembly tool for the production of new energy vehicle connectors, which includes: an assembly base 1, an outer coupling shell 3, a transmission track 2, an inner guide wheel 4, and a positioning and clamping device 6 And the upper assembly assembly 5, wherein, the upper end surface of the assembly base 1 is fixed by the outer coupling shell 3, and the upper end surface of the assembly base 1 is provided with a transmission track 2 transversely, and the transmission track 2 can be relatively The rotating equidistant rows are provided with a plurality of inner guide wheels 4;

[0039] The transmission track 2 is used to horizontally transmit the needle seat of the new energy vehicle connector;

[0040] The upper end surface of the assembly base 1 is provided with an installation recess for installing the positioning and clamping device 6, and the positioning and clamping device 6 positions and clamps the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com