Plastic package coil mould pressing inductor and production process thereof

A plastic-encapsulated coil and production process technology, which is applied in the manufacture of inductors/transformers/magnets, transformers/inductor coils/windings/connections, circuits, etc., can solve problems such as damage to the outer protective layer of the enameled wire, and low and high density of the magnet body. , to achieve the effect of weakening restraint, high molding pressure and sintering temperature, and improving electromagnetic properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0049] This embodiment provides a molded coil inductor with plastic packaging, which can effectively reduce the limitation caused by the physical properties of the conductor itself on the compression molding process of the magnetic powder material, thereby improving the electromagnetic performance of the molded inductor with plastic packaging coils.

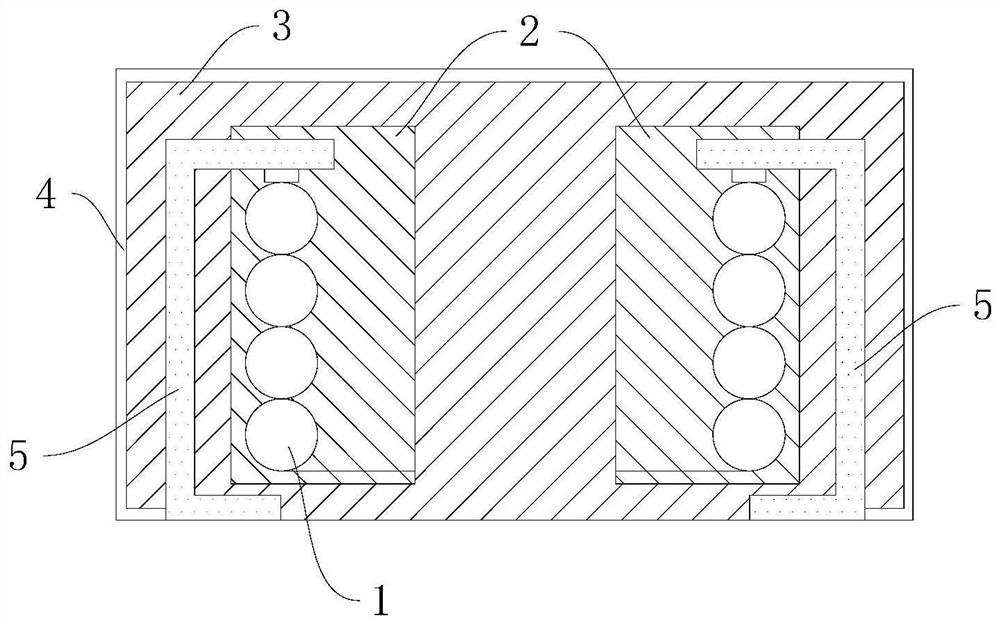

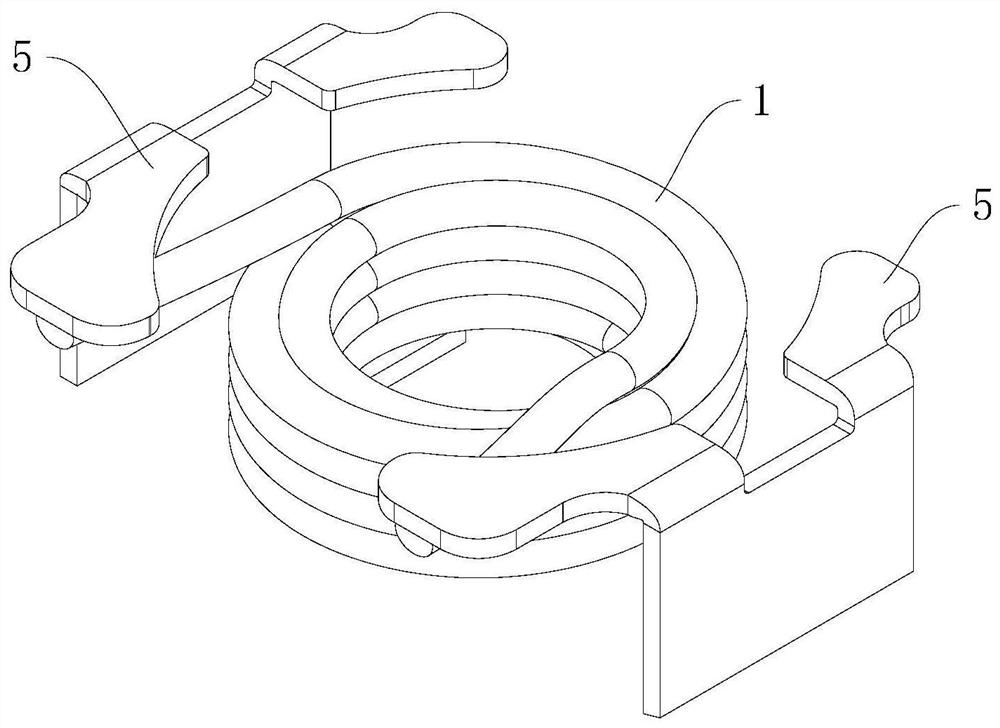

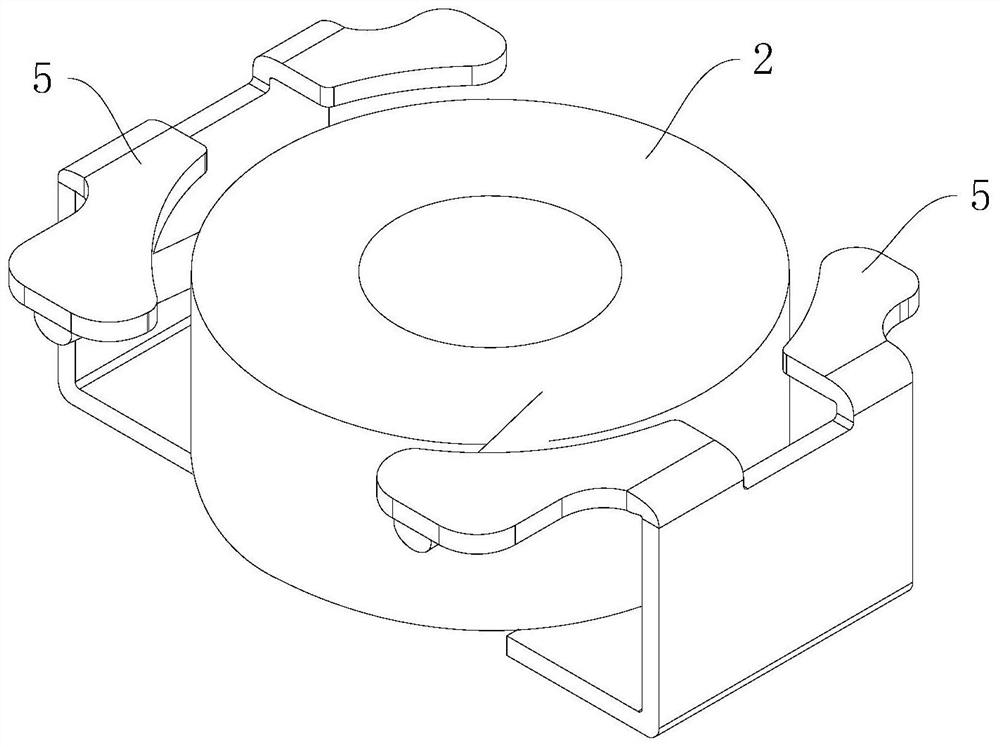

[0050] Specifically, see figure 1 The molded coil inductor includes a conductor 1 for generating an induced current, a plastic layer 2 covering the conductor 1, a magnet body 3 covering the plastic layer 2, and a magnet body 3 covering the body. Protective insulating protective layer 4.

[0051] It should be noted that the conductor 1 is mainly used to generate an induced current under the action of the magnetic field generated by the main part of the magnet 3 after electrification, and its specific structure can be a straight wire, a copper sheet, or a wire wound by an enameled wire. Stereo coils or planar coils are not limited...

Embodiment 2

[0061] This embodiment provides a process for producing a plastic-encapsulated coil molded inductor, which is used for producing the plastic-encapsulated coil molded inductor provided in the first embodiment, and has corresponding functions and beneficial effects.

[0062] see Figure 4 , the production process of the plastic-encapsulated coil molded inductor includes the following steps:

[0063] S10 : forming a plastic encapsulation layer 2 on the outside of the conductor 1 by an in-mold injection process.

[0064] It should be noted that when the conductor 1 is a coil, S10 includes:

[0065] S101: winding the enameled wire to form a coil with a plane structure or a three-dimensional structure;

[0066] S102: Weld the pole piece 5 used for electricity connection at the wire head of the coil;

[0067] S103: Put the coil into the injection mold cavity;

[0068] The pole piece 5 can be completely outside the injection mold cavity, and only the coil is plastic-sealed; the pa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com