Method and device for monitoring rock compressive strength and drillability

A compressive strength, rock technology, applied in the automatic control system of drilling, measurement, drilling equipment and other directions, can solve the problems of low calculation accuracy, high price of measuring instruments or service costs, few factors to consider, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] In order to make the object, technical solution and advantages of the present invention clearer, the embodiments of the present invention will be further described in detail below in conjunction with the accompanying drawings.

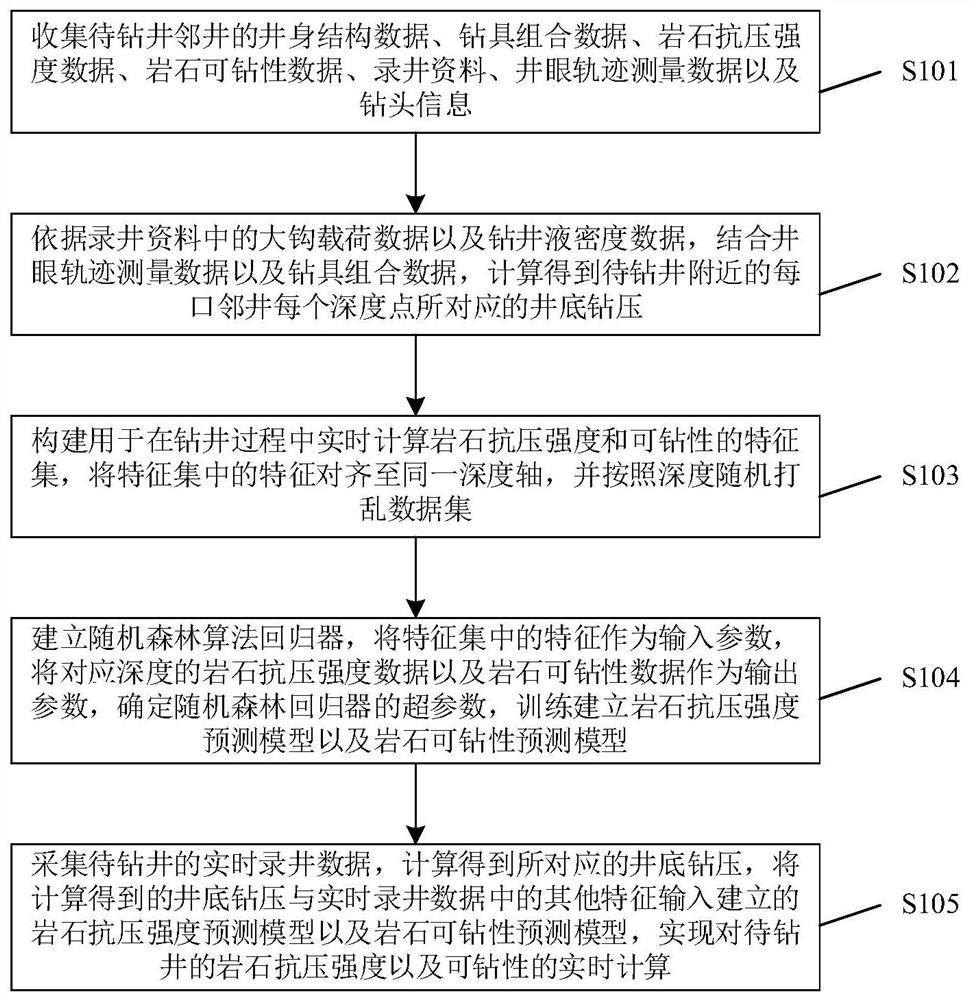

[0042] figure 1 A flowchart of a method for monitoring rock compressive strength and drillability according to one embodiment of the present invention is shown.

[0043] Such as figure 1 , in step S101, the wellbore structure data, drilling tool assembly data, rock compressive strength data, rock drillability data, mud logging data, borehole trajectory measurement data and drill bit information of adjacent wells to be drilled are collected.

[0044] Generally speaking, wellbore structure data includes casing size and casing depth; mud logging data includes rotation speed, hook load, torque, and drilling fluid density; borehole trajectory measurement data includes well inclination and azimuth; drill bit information includes model and size.

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com