A high-temperature solid oxide water electrolysis hydrogen production system and process coupled with solar amino thermochemical energy storage and Karina cycle

A technology of solar energy ammonia and Karina cycle, which is applied in the direction of solar heating system, solar thermal energy, solar thermal power generation, etc., can solve the problems of increased cost, intermittent instability, and large installed capacity, so as to reduce the cost of hydrogen production and couple The system is simple and miniaturized, and the effect of reducing energy storage loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

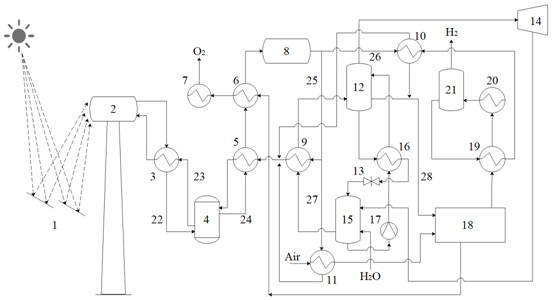

Embodiment 1

[0028] The solar radiation intensity is 1000W / m 2 , the concentration ratio is 200, reflected by the heliostat field 1 to the endothermic reactor 2 (inner diameter 6.2mm, outer diameter 8.7mm, length 1220mm, the reactor material is made of Inconel625, and the reactor is filled with nickel-based catalyst particles, the diameter of the catalyst particles is 0.4-0.6mm), so that the endothermic reactor 2 reaches 800°C, first, the liquid ammonia at 25°C and 30MPa flows out from the liquid outlet at the bottom of the normal temperature pressure storage tank 4, and enters the first heat exchanger 3 Heat exchange and raise the temperature to 400°C, and then flow into endothermic reactor 2 for ammonia decomposition reaction (2NH 3 →3H 2 +N 2 ), the resulting syngas (H 2 +N 2 ) flows out from the outlet and enters the first heat exchanger 3, the heat exchange temperature is 28°C, and then enters the normal temperature and pressure storage tank 4 through the bottom air inlet and is s...

Embodiment 2

[0032] The solar radiation intensity is 1000W / m 2 , the concentration ratio is 200, reflected by the heliostat field 1 to the endothermic reactor 2 (inner diameter 6.2mm, outer diameter 8.7mm, length 1220mm, the reactor material is made of Inconel625, and the reactor is filled with nickel-based catalyst particles, the diameter of the catalyst particles is 0.4-0.6mm), so that the endothermic reactor reaches 800 °C. First, liquid ammonia at 25°C and 30MPa flows out from the liquid outlet at the bottom of the normal-temperature pressure storage tank 4, enters the first heat exchanger 3 for heat exchange and raises the temperature to 400°C, and then flows into the endothermic reactor 2 to undergo ammonia decomposition reaction (2NH 3 →3H 2 +N 2 ), the resulting syngas (H 2 +N 2 ) flows out from the outlet and enters the first heat exchanger 3 with a heat exchange temperature of 28°C, and then enters the normal temperature and pressure storage tank 4 through the bottom air inle...

Embodiment 3

[0036] The solar radiation intensity is 1000W / m 2 , the concentration ratio is 200, reflected by the heliostat field 1 to the endothermic reactor 2 (inner diameter 6.2mm, outer diameter 8.7mm, length 1220mm, the reactor material is made of Inconel625, and the reactor is filled with nickel-based catalyst particles, the diameter of the catalyst particles is 0.4-0.6mm), so that the endothermic reactor reaches 800 °C. First, liquid ammonia at 25°C and 30MPa flows out from the liquid outlet at the bottom of the normal-temperature pressure storage tank 4, enters the first heat exchanger 3 for heat exchange and raises the temperature to 400°C, and then flows into the endothermic reactor 2 to undergo ammonia decomposition reaction (2NH 3 →3H 2 +N 2 ), the resulting syngas (H 2 +N 2 ) flows out from the outlet and enters the first heat exchanger 3 with a heat exchange temperature of 26°C, and then enters the normal temperature and pressure storage tank 4 through the bottom air inle...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com