Method and device for producing efficient organic liquid fertilizer by utilizing biogas slurry

An organic liquid and liquid fertilizer technology, applied in the field of resource utilization of agricultural waste, can solve the problems of low production enthusiasm of fertilizer enterprises, inability to completely remove the odor of biogas slurry, and incomplete deodorization of biogas slurry, so as to improve comprehensive utilization Benefits, flexible formula, wide range of effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

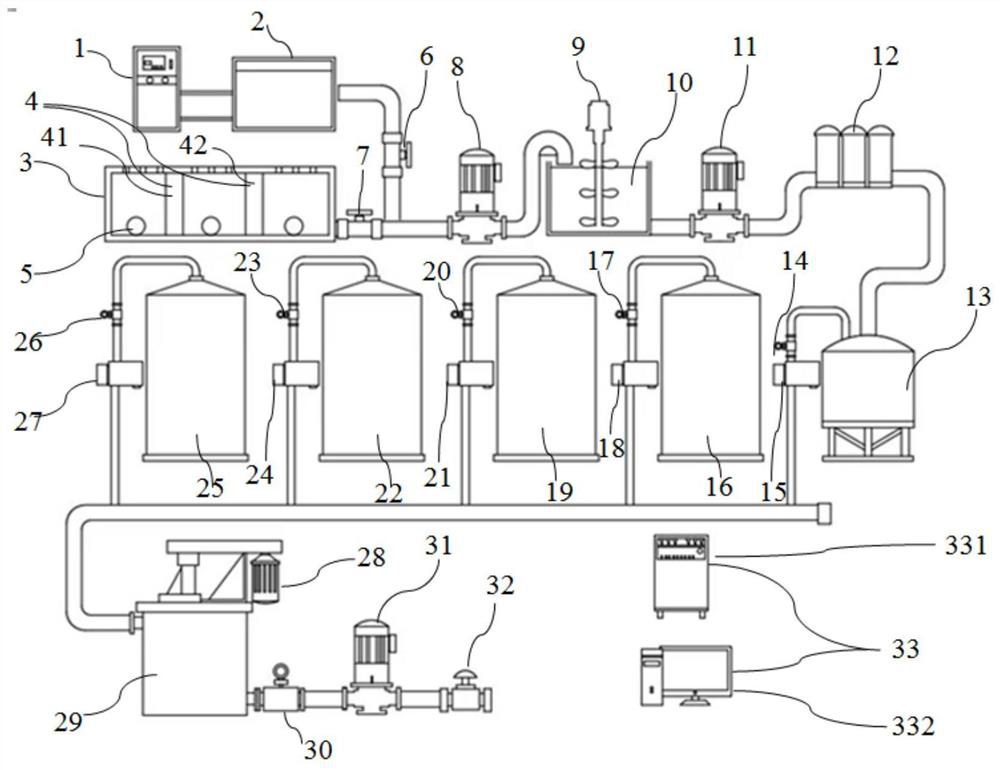

[0042] Embodiment 1 A device used in the method of producing high-efficiency organic liquid fertilizer from biogas slurry

[0043] A device used in the method of producing high-efficiency organic liquid fertilizer by using biogas slurry, the device is composed of a biogas slurry treatment device and a liquid fertilizer mixing device. The biogas slurry treatment device includes: nano-bubble generator 1, bubble pool 2, filter tank 3, filter screen 4, slag outlet 5, first valve 6, second valve 7, first centrifugal pump 8, biogas slurry treatment Pool 10, second centrifugal pump 11, filter assembly 12; liquid fertilizer mixing device includes biogas slurry raw material tank 13, first pneumatic valve 14, third centrifugal pump 15, nitrogen solution tank 16, second pneumatic valve 17, fourth Centrifugal pump 18, phosphorus solution tank 19, third pneumatic valve 20, fifth centrifugal pump 21, potassium solution tank 22, fourth pneumatic valve 23, sixth centrifugal pump 24, medium an...

Embodiment 2

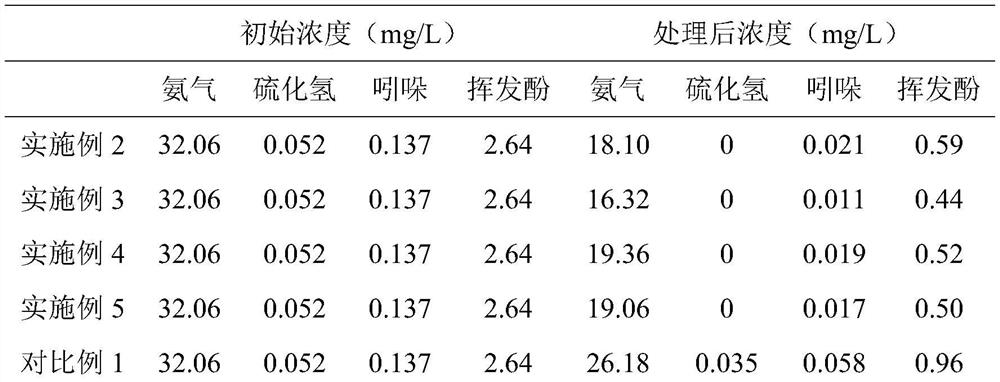

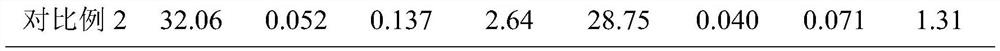

[0046] Embodiment 2 A method of utilizing biogas slurry to produce high-efficiency organic liquid fertilizer

[0047] A method for utilizing biogas slurry to produce high-efficiency organic liquid fertilizer, comprising the following steps:

[0048] (1) Primary treatment of raw materials: Potassium ferrate with 0.005% biogas slurry mass is added to the filter tank, and the reaction time after mixing is 10h for oxidation and deodorization. After deodorization is completed, 2-bromo-2-nitrate with 0.01% biogas slurry mass is added Base-1.3-propanediol bacteriostatic agent to prevent harmful microorganisms from re-breeding; at the same time, use 850μm and 250μm double filter screens to double-filter the primary treatment liquid of the anaerobic fermentation biogas slurry.

[0049] (2) Raw material reprocessing: use a nano-bubble generator to prepare a water source containing a large number of micro-nano bubbles, inject the water source rich in micro-nano bubbles and the primary tr...

Embodiment 3

[0051] Embodiment 3 A method of utilizing biogas slurry to produce high-efficiency organic liquid fertilizer

[0052] A method for utilizing biogas slurry to produce high-efficiency organic liquid fertilizer, comprising the following steps:

[0053] (1) Primary treatment of raw materials: Potassium ferrate with 0.01% biogas slurry mass is added to the filter tank, and the reaction time after mixing is 10h for oxidation and deodorization. After deodorization is completed, 2-bromo-2-nitrate with 0.01% biogas slurry mass is added Base-1.3-propanediol bacteriostatic agent to prevent harmful microorganisms from re-breeding; at the same time, use 850μm and 250μm double filter screens to double-filter the primary treatment liquid of the anaerobic fermentation biogas slurry.

[0054] (2) Raw material reprocessing: use a nano-bubble generator to prepare a water source containing a large number of micro-nano bubbles, inject the water source rich in micro-nano bubbles and the primary tre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com